|

It's hard to imagine back when

only 14 years had passed - to the month - since the Japanese surrendered to the

U.S., that this article with plans for a control line Kawasaki Ki-61 Tony model

was written in the August 1959 edition of American Modeler magazine. The

Imperial Japanese Air Force, like the German Air Force (Luftwaffe), was made up

of highly skilled pilots and increasingly capable aircraft. The Japanese were a

notable more terrorizing enemy since many were willing to sacrifice their lives

in battle, whereas the Germans were more of the mindset of living to fight another

day. It is now 52 years hence since this article was written and very few of the

men who fought WWII - on all sides - are still alive to bear witness to the action.

As long as there are people who want to dominate the world, there will be wars.

Today, it's militant Islam that wants everyone to submit to Sharia law. The difference

with this fight is that political correctness prevents us from winning by conjuring

"rules of engagement" that are more likely to get our soldiers killed than the enemy's.

All of the lawmakers should be required to fight on the front lines for a month

under the rules they impose on the troops.

Kawasaki Ki-61 "Tony"

Kawasaki Ki-61 Tony

Slick World War Two Control Line Scaled 3/4 Inch to Foot

by Walter A. Musciano

The only Japanese single seat fighter to be powered with an inline liquid cooled

engine during World War II was the Kawasaki Ki-61. This plane was used by the Japanese

army virtually throughout the war in New Guinea, Rabaul, China and Philippines and

over Japan intercepting B-29 bombers. The Ki-61 is generally considered to be the

Japanese Army's counterpart of the Japanese Navy's vaunted "Zero." The U.S. recognition

nickname for the Kawasaki Ki-61 was "Tony."

The 3,120 "Tony" fighters that saw service were powered by a twelve cylinder,

Vee type engine of 1175 horsepower, designed Ha-40. This was undoubtedly a German

design built in Japan under license. In fact, the entire treatment of cowling and

exhaust stacks gives "Tony" a typical German rather than a Japanese appearance.

Maximum speed was 348 mph with a gross weight of 7650 lbs. The craft could climb

to 16,400 feet in seven minutes. Armament consisted of two 20 mm cannon mounted

in the wings outside of the propeller arc and two heavy calibre machine guns buried

in the cowl. This was one of the few Japanese planes that was well armored.

Sporting Chinese insignia, Jap Tony (upper left) like one above

shows influence of Germans. Full size plans for constructing a Ki-61 model are available

on Group Plan #859 from Hobby Helpers, 770 Hunts' Point Ave., New York 59, N. Y.

(85c). When ordering specify plan number desired, rather than name of model.

An air cooled engine version was also produced in limited numbers during the

closing years of the war. This was the Ki-100. Reports indicate that the Kawasaki

Ki-100 could meet U.S. "Mustangs" on equal terms and the better pilot usually won.

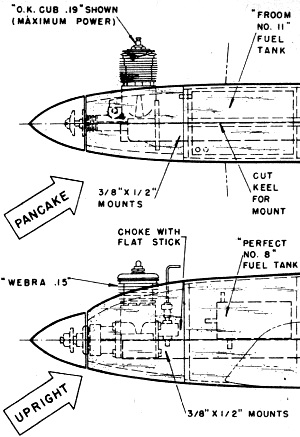

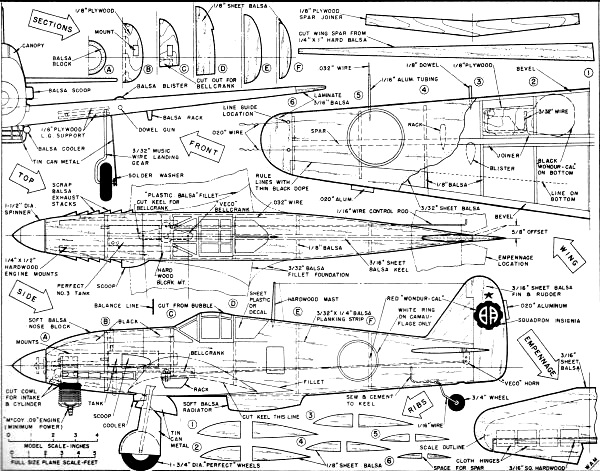

"Tony" is beautifully proportioned for control line sport flying and this 3/4"

to the foot scale model can be powered by a glow plug or diesel engine from .09

to .19 cubic inch displacement. Standard two line control system is shown; however,

the Stanzel Mono-line control system can be installed if desired. The clean, uncluttered

lines and absence of struts or rigging makes this "Tony" a pleasure to own and fly.

As is customary with our vertical keel fuselage construction, the wing is built

first. Begin by cutting the spar and ribs to shape and cementing these together.

The 3/32" sheet lower covering should be assembled to form the correct chord distance

from standard 3" balsa sheets. When the covering has been assembled and cut to shape

it can be cemented to the bottom of the ribs and spar. Start with the spar and work

the covering towards the leading and trailing edges of the ribs. Use plenty of cement

and hold the covering in place with pins until the cement is dry.

Bend the wire landing gear struts to shape being certain to make one left- and

one right-hand strut. Sandwich the upper portion of the struts between two rectangles

of plywood. Drill small holes and firmly "sew" this assembly together. Use plenty

of cement. When dry, the landing gear is cemented to the wing spar, ribs and lower

covering. This is done by passing the strut, from above, through the lower covering

in the exact location that· the strut emerges at the bottom. Do not spare the cement

in installing the landing gear. Several applications are recommended.

The 3/32" sheet balsa wing upper covering is installed in the same manner as

the lower. Before this is attached, however, be sure to bevel the leading and trailing

edges of the lower covering to match the contour of the ribs' upper camber.

Sheet balsa wing tips are laminated of 3/16" sheet balsa and cemented in place.

Entire wing should be sanded thoroughly at this time with 3/0 sandpaper.

Cut the body keel to shape and cement it to the wing. Be certain to cut openings

in the keel for the fuel tank, and bell-crank movement. Cut the bulkheads and formers

to shape and cement these to each side of the keel. Install the engine mounts to

the bulkheads using plenty of cement.

The elevator and stabilizer are cut to shape, sanded to a streamline section,

and hinged together after the control horn has been firmly installed. Cement the

stabilizer into the slot in the keel.

A hardwood block serves as the bellcrank mount. Attach the lead-out lines to

the bellcrank and then bolt the bellcrank to the mount. Slip the control rod onto

the horn and bellcrank and then cement the mount very securely to the top of the

wing. It will be necessary to make a small hole in the wing covering to accommodate

the nut.

Install your "commercial" fuel tank at this time. This must be rigidly wedged

in place.

The fuselage is planked with 3/32" x 14" balsa strips. These should be carefully

fitted and cemented to the fuselage formers as well as to each other. Hold in place

with pins until cement dries. Small hairline spaces between the planking strips

caused by improper fitting can be easily filled with "Plastic Balsa." When the planking

is complete the nose block should be installed. Install the engine mounting nuts

and bolts tightly. Apply plenty of cement around the nuts to hold them in place.

Carve the nose block roughly to shape and then split it apart along the horizontal

centerline. Hollow the interior to clear the engine mounts; and then cement the

nose to the fuselage. Complete the nose and sand the entire fuselage thoroughly.

Cement the wing fillet sheet balsa foundation to the wing and fuselage. When

dry apply several layers of "Plas-tic Balsa" with the fingers to form the fillet.

Make the fillet slightly oversized to allow for sandpapering when the "Plas-tic

Balsa" is dry.

The fin and rudder should be cemented in place.

Carve the radiator from soft balsa and sand smooth. Cement this to the fuselage

belly and form fillets with "Plastic Balsa."

The windows forward of the cockpit and the rear vision panels behind the cockpit

are cut out and covered with sheet plastic. The planking should be cut away about

1/32" all around the opening. This cut must be to a depth equal to the thickness

of the plastic sheet. Carefully cut the plastic to 1/32" larger than the opening

and cement it in place.

Seal any rough edges or imperfections around this installation with "Plastic

Balsa." Sand smooth. Those modelers who are not interested in these details can

use black or blue decal sheet for the windows and this can be applied after the

model has been painted.

At least six coats of Balsa Filler should be liberally applied. Sand each coat

when it is thoroughly dry. Up to twenty coats can be applied for a super finish.

The Kawasaki can be colored all light gray with black anti-glare panel forward

of the cockpit, or it can be colored all bright green or bright green with splotches

of yellow and a hazy blue bottom. The red ball insignia is outlined with a white

band only when the plane is camouflaged.

The splotches of yellow on the green are made by cutting yellow "Wondurcal" decals

into small irregular pieces and applying them onto the finished model. These will

adhere tenaciously and are fuel proof.

The cockpit canopy can be cut from a standard bubble. many of which are available

at most hobby shops. This should be installed now. Other miscellaneous details such

as exhaust stacks, radio mast, tin can metal wheel covers, and wheels are added.

Carefully cut a hatch in the cowl in order to install the engine. Loosen the

mounting bolts gently in order not to the nuts that were previously cemented to

the mount. Openings for the cylinder and needle valve are cut in the nose. The entire

cowl interior should be well protected with several coats of fuel proof dope. Install

the engine and attach the cowl hatch with a few drops of fuel proof cement.

The model should balance at the point shown. Lead weights, firmly attached to

the inside of the nose or tail, should be used to remedy any unbalanced condi-tion.

In view of the relatively small wheels it is advisable to fly your "Tony" from

a paved area or grassless packed earth. Flight lines thirty to fifty feet long can

be used for flying this model. The prototype airplane was flown with a three bladed

propeller.

Kawasaki List of Material

Material is Balsa except where otherwise noted.

Three 3/32" x 3" x 36" for wing covering; (1) 1/8" x 3" x 36" for wing ribs,

fuselage formers; (1) 3/16" x 3" x 36" for tail surfaces, wing tips; keel; (1) 1/4"

x 1" x 36" for spar; (15) 3/32" x 1/4" x 36" for fuselage planking; (1) 1/8" x 6"

x 12" plywood for wing Joiner, bulkheads, landing gear supports; (1) 1/4" x 1/2"

x 12" hardwood for engine mounts; (1) 3/32" dia. x 18" music wire for landing gear;

(1) 1/16" dia. x 24" music wire for control rod, tall wheel strut; (1) 3" x 3" x

3" for cowl, radiator, scoop; (1) Berkeley Canopy; 8 oz. Aero Gloss Balsa Filler

Coat; 4 oz. Aero Gloss Swift White dope; 1 oz. Aero Gloss Jet Black dope; one sheet

red Wondurcal decal.

Miscellaneous - Straight pins; "3/0 dry sandpaper; 6/0 and 8/0 sandpaper; brass

washers; Aero Gloss Plastic Balsa; one tube Ambroid Cement; small jar clear fuel

proofer to protect canopy; aluminum spinner.

Color note - add the black dope to tile whit. a little at a time until a pearl

grey is obtained - use the remaining black for the landing gear struts and the anti-glare

panel forward of the cockpit.

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted December 9, 2021

(updated from original post on 8/14, 2011)

|