|

Do a Google search on "variable inductance servo" or "inductive

feedback servo" and you will not find anything useful. That alone

these days is sufficient to prove that the concept never caught

on in popularity. I don't think it is because the configuration

is not good, it is just that the problems associated with early

potentiometer feedback elements were solved long ago. Prima facie

evidence of that is seen in the millions upon millions of servos

sold yearly for model airplanes, helicopters, cars, boats, and drones.

They all use servos with potentiometers mechanically coupled to

the rotating output shaft.

|

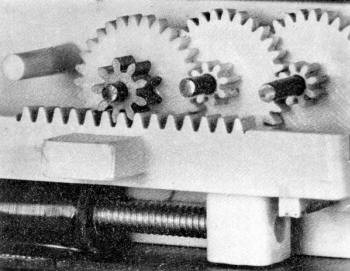

Rotary output servo gear train.

BTW, before you are tempted to dismiss the cosine relationship

as not being exponential, recall that the Euler identity

for cosine is shown above.

|

That said, this article is an excellent example of research and

development performed to solve a serious problem and coming up with

a workable solution. Many alternatives were tried, including capacitive

feedback and optical feedback. Size, weight, and reliability finally

excluded all but the variable inductor.

I

will take this opportunity to say that I have never understood why

the servo industry adopted the rotary output (rotating shaft) configuration

rather than the linear output (sliding). Because pushrods direct

force approximately along a straight line, more movement is produced

near neutral rotational displacement, then tapers off according

to cos θ as the transmitter control stick is moved. Typical

servo rotation is ±60°, so the linear transformation

ranges from nearly 1:1 around 0 to 0.5:1 at 60°. Modern computer

radios offer the ability to programmatically cancel out that response

using what is termed 'exponential

response'. This is necessary because the flier usually wants

less responsiveness near neutral and more near the extremities because

the model flies more smoothly. I

will take this opportunity to say that I have never understood why

the servo industry adopted the rotary output (rotating shaft) configuration

rather than the linear output (sliding). Because pushrods direct

force approximately along a straight line, more movement is produced

near neutral rotational displacement, then tapers off according

to cos θ as the transmitter control stick is moved. Typical

servo rotation is ±60°, so the linear transformation

ranges from nearly 1:1 around 0 to 0.5:1 at 60°. Modern computer

radios offer the ability to programmatically cancel out that response

using what is termed 'exponential

response'. This is necessary because the flier usually wants

less responsiveness near neutral and more near the extremities because

the model flies more smoothly.

A linear output servo addresses three negatives: 1) it removes

the nonlinear nature of the control surface deflection, 2) the rack

and pinion gears driven by a worm gear isolates the motor from the

reverse forces placed on the servo control arm, and 3) battery power

is not required to counter the aforementioned reverse force on the

motor (otherwise the motor might be momentarily

backwards to hold the control surface in position). There

must be a good reason for it, though. Melanie suggested maybe there

is an all-encompassing patent on the linear output servo that would

make licensing and manufacturing prohibitively expensive. I welcome

input regarding this issue.

The Variable Inductance Servo

John Cline, Engineer, F&M Electronics

|

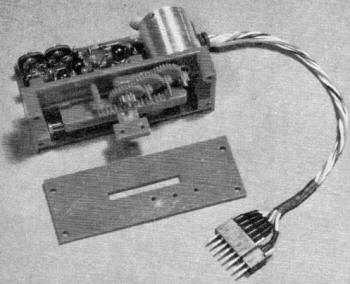

No accuracy or performance is lost with variable inductance.

Output is linear and has 3/4 in. total travel. Easily mounted.

Variable inductance is accomplished by moving a bar of

iron (a length of 4-40 steel bolt) inside the bobbin of

the tightly wound coil on the left. This bar screws into

the output arm of the servo and its position is adjustable

for servo centering.

|

Design and development of a new kind of feedback servo. An important

article for the well-informed enthusiast and the scientifically

inclined reader.

Feedback control systems, either digital or analog, must utilize

some form of feedback component to provide the appropriate reference

signal denoting servo output position. Radio control systems have

characteristically used the potentiometer as the feedback component,

either in the form of a linear wire-wound element or a circular

fired ceramic element contacted by wipers. They are subject to performance

deterioration caused by vibration, dirt and oxidation, which interrupts

contact between the wiper and the element or to more drastic failures

caused by breakage of the wire wound or ceramic element. The desirability

of replacing the potentiometer with a feedback component which requires

no phy-sical contact has long been unquestioned; however, the implementation

of other techniques has not been fruitful until recently.

Our initial attempts to eliminate the pot problems were directed

toward improving it as the feedback element. During this investigation

it was found that most of the wear in the pot was not caused by

actual control movements but instead was located in a very narrow

band around the center position of the servo as the result of control

surface flutter being transmitted to the servo assembly through

the pushrod. In general, in a system in which the servos have not

been periodically rotated between control functions, the R, E, and

A servos show markedly greater pot wear than does the throttle servo

pot.

Samples of all available commercial potentiometers were procured

and evaluated for application to feedback servos. We found that

some were unsatisfactory for reasons of: 1) Size, 2) Susceptibility

to wear, 3) Operating torque, 4) Ease of breakage, and 5) Exposure

of wipers to foreign matter. Of the types evaluated, the fired ceramic

type with a sealed housing was found best. However, it was felt

that the feedback technique still required further improvement.

Design Goals. The requirement for any replacement

for the conventional feedback potentiometer was established to be:

a) No wiping contacts; b) As economical as the potentiometer; c)

No more complex than the conventional servo; d) Easy alignment and

adjustment; e) Easily manufactured, including ready availability

of components; f) Weight and volume not to be compromised. Alternative

Approaches. Electronically, the conventional feedback potentiometer

is used as a voltage divider. A fixed voltage is applied across

the pot and the wiper serves to establish reference voltage as it

moves along the element. Arrangement is such that the voltage appearing

on the wiper is directly proportional to the position of the servo

output arm. In the digital system this voltage is used to govern

the duration of a reference pulse generated for comparison with

the incoming control pulse and the reference pulse is made to be

directly proportional to the actual position of the servo output.

The first approach undertaken was a modification to existing

circuitry using a variable capacitor in the monostable multivibrator

used to generate the reference pulse. A single-shot, or mono-stable

multivibrator, exhibits a pulse duration which is determined by

a capacitor-resistor time constant. From a theoretical viewpoint,

it is possible to change this time duration by changing the value

of either the capacitor or resistor; however, this approach was

discarded in favor of using a new design approach which utilizes

an induction as the variable component in the reference generator.

|

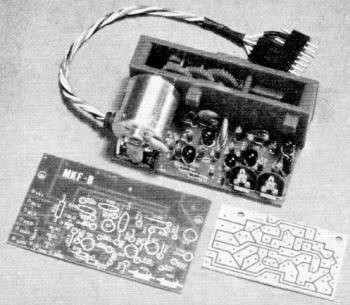

Servo under construction shows the kit's two etched and

printed PC boards whose parts are widely separated for easy

assembly.

The gear train gives lots of power and speed, three pounds

thrust and 0.6 sec. end-to-end movement. A durable and rugged

assembly.

|

The next approach involved using a variable inductor in a conventional

single-shot. An inductor-resistor also represents a time-constant

circuit. It is not practical to substitute a variable inductor directly

in a conventional single-shot reference generator because approximately

0.2 henrys of inductance is required. In our application this means

that the inductor would weigh at least 4 or 5 ounces, which would,

of course, be prohibitive.

We next examined the use of light intensity as the variable.

This system could be implemented by using a standard light bulb

for a light source and using a photodiode or photoresistor as a

detector of this light. By placing a sliding screen between the

source and the detector and making the screen such that its transparency

is a function of the position of the screen, one could achieve an

appropriate reference parameter in or at the detector which would

be directly proportional to the position of the screen sliding between

the light source and the light detector. The author had done some

previous work with this type system and found it to be most successful.

This type technique would satisfy a great majority of the requirements

established for the servo feedback element; however, it was determined

that there were four deficiencies which made the technique impractical:

a) Limited bulb life and catastrophic failure with no warning; b)

Poor vibrational environmental characteristics; c) Excessive battery

drain required to drive the light source; d) Impractically expensive.

Aircraft AC autopilots commonly use an inductor known as the

linear variable differential transformer as the feedback component.

Some basic experimentation proved this to be impractical in our

application. The differential transformer required is large and

has multiple windings, is difficult to produce or procure.

Design of Preferred Alternative. It was concluded

that any further attempt to use inductive or capacitive feedback

would have to involve new reference circuitry instead of the conventional

single-shot reference generator and, further, that they could not

be used in their conventional timing sense.

It is required that the digital servo operate on a delay on the

order of one millisecond because the FCC regulations limit the band

width of our equipment. Any further decrease in the delay means

that the limit would be exceeded.

The use of a variable inductor in a new timing circuit was investigated

next and proved to be an acceptable approach. It seemed reasonable

that one could use the reverse induced EMF which appears across

an inductor when the current in the inductor is changed. Going back

to basic electronics, you will recall that if a steady state DC

current is established in an inductor, and then is interrupted,

or turned off, a voltage is induced across the terminals of the

inductor. The magnitude of this voltage is a function of the magnitude

of the current which was being passed through the inductor and the

speed with which the current was turned off. It is also a function

of the actual inductances of the coil itself. The formula for this

induced EMF is E = L di/dt. Because the inductance is a function

of the permeability of the magnetic flux path, it is quite simple

to change the inductance of a given coil by moving an iron core

in and out of the coil.

For example, this same mechanism is used in the RF coils which are

used to tune the receiver in radio control systems. Visualize an

inductor wound on a straight hollow form with an iron core moving

in and out of the coil and you have an inductor whose value of L

is dependent upon the position of the core in the coil. In the servo

application, this core could be rigidly attached to the moving output

arm of the servo while the coil would be fixed to the stationary

portions of the servo. Hence, the position of the core would be

determined by the position of the servo output, hence the value

of inductance would be proportional to the position of the servo.

By passing a fixed DC current through the inductor, and then turning

it off abruptly, a voltage would be induced across the terminals

of the inductor with the magnitude of the voltage proportional to

the position of the servo. By properly designing the electronic

circuitry, we produce a voltage proportional to servo position and

achieve a feedback element which does not require wiping contacts.

The problem remaining is to generate, from this induced voltage,

the time delay approximately of 1 millisecond and, at the same time,

maintain a direct relationship between the magnitude of the induced

voltage and the duration of the time delay.

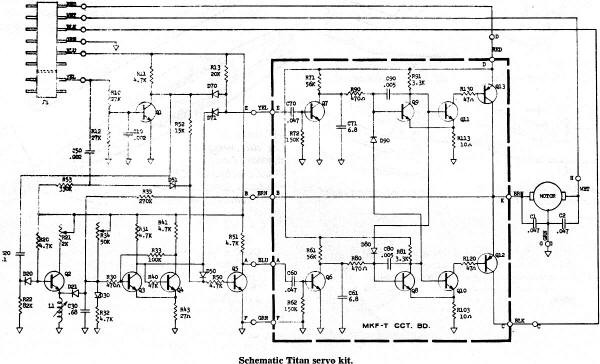

Mechanization of the preceding approach has been successfully

achieved in the Titan Magnevac servo. In order to discuss this mechanization,

refer to the schematic. The general functions of the different portions

of the circuitry are as follows: Q1 is an input buffer and amplifier.

Transistors Q2, Q3, Q4 with the variable inductor, L1, and associated

resistors and capacitors, form the reference pulse generator. Diodes

D70 and D71 form the comparator gate for one direction of servo

travel, and D50 and D51 and resistor R52 form the comparator gate

for the other direction of travel. Q5 amplifies and inverts the

output from the latter half of the comparator.

Transistors Q7, Q9, Q11 and Q13 form a pulse-stretching network

and the driver transistor which causes the motor to run in one direction

and transistors Q6, Q8, Q1O, and Q12 produce the opposite direction

of travel.

Let us now investigate the operation of transistors Q2, Q3, and

Q4. The inductor L1, is the feedback element and is located in the

emitter leg of transistor Q2. Resistor R20 (4.7K on the base of

Q2) biases Q2 ON so that, in the normal quiescent state, transistor

Q2 is conducting and draws a steady state DC current of about 3

milliamperes through inductor L1. Q3 and Q4 are cross coupled in

the basic Schmidt trigger configuration with transistor Q3 biased

ON and Q4 biased OFF. The collector of transistor Q3 is the output

of the reference generator and is coupled into both comparator gates.

With Q3 biased normally ON, the output, or collector of Q3, is at

or near ground potential.

The reference generator is triggered once each frame by the command

pulse routed to each servo via the yellow lead of connector P1.

This is a positive going signal whose duration (width) specifies

commanded servo position and is the one millisecond duration mentioned

earlier. This pulse turns on transistor Q1, thereby generating a

negative going pulse with a duration of 1 millisecond on the collector

of Q1. The rise and fall of this negative going pulse is differentiated

by C20 and R22 to form first a short negative going spike, and then

a short positive going spike 1 millisecond later. The negative going

spike is coupled through diode D20 to the base of Q2 and turns Q2

OFF i.e., causes it to stop conducting.

This means that the current has abruptly ceased to flow through

inductor L1 and a reverse voltage is induced across L1. Thus, the

top of L1 (the emitter of Q2) is caused to go negative for a short

duration. The magnitude of this induced voltage is dependent upon

the position of the core in the inductor L1. When the servo is at

one end of its travel and the core is only slightly projecting into

the coil of L1, this induced voltage is in the order of minus 20

or 30 millivolts. However, at the other end of its travel, when

the core is projecting entirely through the coil of L1, the magnitude

of this voltage is as much as minus 200 millivolts. This negative

going voltage peak is coupled through diode D21 into capacitor C30,

and, because of the low resistance of the inductor L1 and low forward

resistance across diode D21, capacitor C30 is caused to discharge

abruptly. When the voltage decays across L1 and the emitter returns

to its DC level, diode D21 becomes reverse biased.

The positive going time constant (decay time) for capacitor C30

is determined primarily by the resistance value of trimming potentiometer

R34. This causes capacitor C30 to recharge toward 6 volts with a

time constant which is determined by C30 and (primarily) R34. The

fact that the junction between C30 and R34 has abruptly become a

negative voltage has caused Q3 to be turned off, thereby causing

its collector to go positive. This action causes Q4 to be turned

on.

The base of Q3 now recharges toward 6 volts until Q3 is again

caused to conduct, and through the Schmidt trigger action, Q3 quickly

turns back on thus turning Q4 off. One cycle of operation of the

reference generator in now complete and the output, or collector

of Q3 has changed state for a period of approximately 1 millisecond.

As the core is moved further into inductor L1, the negative induced

voltage becomes greater, thereby causing capacitor C30 to be further

discharged. Since capacitor C30 recharges at a constant slope, it

can be seen that for larger negative voltages, we generate a longer

time delay during which transistor Q3 is off. This is the basic

mode of operation of the Magnevac timing circuitry. A U.S. patent

is pending on the circuitry around Q2, Q3, and Q4 and should be

granted very shortly.

The remaining circuitry of the servo is more or less conventional.

Position of the servo is a function of the input pulse width. The

reference pulse is compared to the input pulse, and the appropriate

pulse stretching and driver chain is turned on depending on whether

the commanded pulse is wider or narrower than the reference pulse.

This process is repeated once each pulse repetition period until

the widths of the reference and commanded pulses coincide to produce

a nulled condition.

A photograph shows the mechanical arrangement of the inductor

and the core. Notice that the inductor itself is a coil-form which

is attached rigidly to the printed circuit board of the servo. The

core that moves in and out of the inductor is a soft steel continuous

threaded 4-40 rod with a screw driver slot in one end for adjustment.

The slug threads into the post which is an integral part of the

output rack. When the rack or output arm of the servo moves, the

slug moves with it, in and out of the inductor. The center position

of the servo is readily adjusted by screwing the core into or out

of the post. If this adjustment is performed with a nonferrous screw

driver, the position of the servo can be adjusted for proper centering

while the servo is operating. The resolution of this adjustment

is exact.

Servo Development. Referring again to the schematic

you notice that both R21 and R34 are potentiometers which provide

for adjustment. R21 adjusts the DC current which flows through the

inductor to change the absolute magnitude of the voltage induced

across L1 when transistor Q2 is turned off. R34 controls the recharging

time for capacitor C30. Thus, adjustment of R34 changes the slope

with which C30 recharges toward 6 volts. Hence, it is possible to

adjust both the end and the center positions of servo travel.

Extensive testing has established that the linearity of the inductive

feedback principle is better than one-half percent as measured against

the theoretical straight line. Linearity is lacking only at the

extreme ends of the coil-form. This is due to the fringing effect

of the magnetic field at the ends of the coil. However, since servo

travel is restricted to 3/4 in. and the coil is a full one in. long,

the fringing, or end effect, is not observed in normal operation.

The final version of the Titan Servo was designed to provide

a full 3/4 in. permissible travel on the output arm and a transit

time of about 0.6 seconds end-to-end. The thrust is 3 1/2 pounds.

The case is made of 0.032" half hard aluminum anodized blue and

is mountable on three sides. The case has proved to be extremely

durable and most resistant to crash damage. The size of the Titan

Servo is 1 1/16" thick by 1 3/4" high by 3 1/4" long including mounting

lugs.

The variable inductance servo is available in a wide range of

models for use with most major brands of digital equipment today.

Schematic from Titan Servo Kit.

Posted June 9, 2014

|