|

Seaplanes

have always been a popular topic with modeler and full-size pilots

alike. There's something about watching an airplane take off from

or land on the water that is awe-inspiring. Flying without the constraints

of a narrow runway certainly has its advantages, but there is an

added element of risk with seaplanes because of potential damage

that can be caused by water entering the airframe or even damaging

it. The possibility of drowning, even after making an otherwise

perfect landing, exists for the full-scale pilot, and the modeler

can lose equipment that otherwise might be salvagable. This article

is pretty extensive and give a lot of food for thought concerning

taking on rise-off-water (ROW) operation. I looked up the tail number

(N3763C) of the Cessna 150 shown, but either it has been retired

or it hasn't changed owners in lo these many years. Rx for R.O.

W.

Having covered the floats and hulls in the last issues,

Part II discusses the important aspects of good model airplane design

for water operation. How to waterproof, converting land planes,

taxiing, landing and takeoff of seaplanes. By George

Wilson

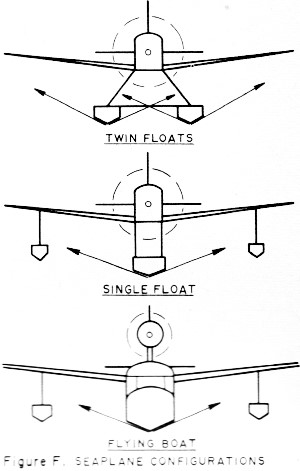

Seaplane configurations. |

There are two approaches to seaplanes: 1) Convert a landplane to

a seaplane and, 2) build an airplane which is initially designed

to be a seaplane. Obviously, the latter approach should give the

most satisfactory results. On the other hand, it has been solidly

demonstrated that a landplane with floats added can be an excellent

water performer. Seaplane Configurations: The first consideration

is whether to use one or two main floats. A single main float is

easier to build and causes less drag both on water and in the air.

A single main float - on a single-engined airplane - also has the

inherent advantage of minimizing the amount of spray that passes

through the propeller. Figure F shows configurations most frequently

used. Notice the spray paths that are possible during the early

part of takeoff run. At this time it is important that the propeller

devote all its effort to pulling (or pushing) the airplane through

the water. When spray goes through the propeller, power output is

seriously reduced. A seaplane riding on the step will often lose

this position and sink almost back to the waterline because of loss

of speed resulting from a splash of spray. An incidental factor,

is propeller erosion. If wooden props are used they will quickly

loose their tips as a result of water (spray) impinging upon them.

Nylon props appear to withstand this abuse. The superiority

of the single main float design is attested to by its choice for

full scale aircraft. Only on rare occasions such as the Italian

Savoia-Marchetti S-55 has a two pontoon seaplane design been evolved

except for conversion of a landplane to a seaplane. As an

aside for those interested in the engineering and mathematical side

of our hobby, the scale effects of hydraulics are not similar to

those of aerodynamics. In the latter case we have to deal with a

very non-linear situation (Reynold's number) which makes the application

of full-scale data to models completely impractical. The hydraulic

case is essentially linear - the equivalent to Reynold's number

is the Froude number - and, therefore, full-scaled data can be scaled

easily for model use. Another way of saying this is that water will

flow around model floats in the same manner that it flow around

full-scale floats. Airflow around models is quite different than

full-scale, requiring changes in area, dihedral angles, decalage,

etc. Single main floats require support on each side to

prevent the airplane from falling to one side or the other. This

is normally accomplished using "tip floats."

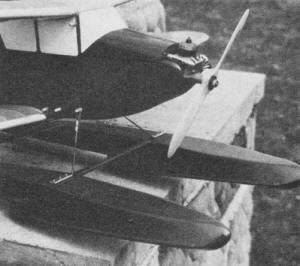

In many respects full-scale experience fits

typical model floatplane requirements- the 1967 Cessna 150 (for

example) on floats.

"Sponsons" attached to the main float have also been used

- like small wings mounted at the waterline, which provide the floatation

necessary to prevent capsizing while floating. Properly designed

sponsons provide some added lift. Sponsons never provide the positive

protection against capsizing that tip floats do. On the other hand,

it could be theorized that they would be less apt to cause "water

looping." As a practical matter, the tendency for seaplanes with

tip floats to water loop is very small. The drag caused by these

floats appear to be small with respect to that of the main float.

Additionally, the inertia of the fuselage and main float helps maintain

a near straight path even when a tip float touches first on landing

or digs in a bit on takeoff. Sponsons can be rigidly attached.

Tip floats should be attached flexibly and must have break-away

capability. All things considered - and perhaps for the basic reasons

that they are more like scale - the author prefers tip floats. It

should be noted here that the same rules apply to tip floats and

sponsons as apply to main floats. In either case their size should

be minimized to reduce drag both in the water and in the air.

Most flying boats make fine landplanes by the addition of

wheels. For temporary usage, these may be attached to the bottom

of the float using rubber bands. Care should be taken to prevent

the gear from marring the under surfaces of the float - a layer

of plastic foam will usually provide the necessary isolation.

Conversion of Landplanes: The easiest way to convert

a landplane is to add floats. The most popular system is to add

a pair of main floats - as is done in most full-scale conversions.

When a low-wing airplane (or biplane) is converted. it appears highly

desirable to consider the use of a single main float with tip floats

under the wings. In either case, three things must be considered:

1) additional fin area. 2) increased power, and 3) waterproofing.

The latter problem will be covered later, but it must be mentioned

here since it is critical to the decision of whether or not a conversion

should be attempted. If you are starting from scratch and not just

adding floats to an existing model, you can handle the waterproofing

properly. On the otherhand, if you are adding floats to an existing

airplane, have a look at the part of the article on waterproofing

before you proceed. It takes more than clipping your receiver in

a plastic bag to do a minimum waterproofing job. There is nothing

quite like a few soaking-wet balsa parts for changing the balance

of a model; or, worse yet, one section of the rudder or elevator

filled with water and not noticed until the model starts stalling

all over the sky shortly after takeoff. Because of the added

weight it will be well to use a little added power. You shouldn't

have to go more than one motor size higher if you use the proper

floats. Your model will tend to fly and take off slower with floats.

For this reason it may be well to try a propeller with less pitch

than you would normally use. Matching airspeed with propeller pitch

is something most of us do to maximize the motor's performance.

However, the choice of propeller should be reviewed as part of the

conversion.

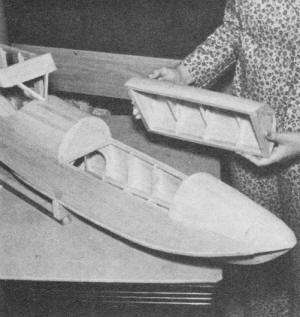

Waterproof hatch construction requires flat surfaces. Seal

it with silastic.

Waterproof toggle switches mounted on the hatch. Switch

on before starting engine.

Floats must be well braced, securely mounted and very durable.

Lots of dope and wax. |

Increased fin area is necessary to compensate for the profile area

added by the floats. The fin, and rudder of any airplane assures

that it will fly in a straight line if none of the control surfaces

are actuated. The basic rule states that the side area of the airplane

behind the center-of-gravity must be greater than the side area

in front of the CG. This is a fancy way of saying that the airplane

is like a weather vane; the area behind the CG makes the airplane

"weathercock" with its nose forward. A "sub-fin" located under the

normal fin and rudder, twin auxiliary fins near the elevator tips,

or auxiliary fins at the end of the float(s) are generally used.

An area about one-third that of the total fin plus rudder area is

generally satisfactory. If the model tends to wobble from

side to side in the glide and is over-sensitive to rudder commands,

additional fin area should be added. Many people agree that a larger

than necessary fin in this type of model is desirable to promote

added directional stability. In "thermal hunters" and airplanes

requiring extreme maneuverability it is not the case. In a seaplane,

inherent stability would appear to be an asset in any case. Although a number of stunts are possible with a seaplane, it is

not an ideal stunt configuration. Most seaplanes have a low CG which

results in what is known as a "pendulum" stability. The fuselage

and floats hang like a pendulum from the wing, It is interesting

to watch some seaplanes when they right themselves after a maneuver;

their lower sections actually swing back and forth like a pendulum.

At high speeds in turns this same pendulum effect can cause excess

banking. A docile airplane like the Seacat can lock itself into

a turn with its wings vertical if a tight, high speed turn is called

for. Once understood, the situation can be guarded against or, if

it happens accidentally, it can be "unwound." One wrong control

can cause a spectacular spiral dive, followed by a large splash.

In the first section of this article the necessity of rigid

float mounts was pointed out. We mention it again here to re-emphasize

importance. It would be a good starting point in your conversion

planning - along with the waterproofing investigation - to assure

yourself that rigid float struts can be added to your particular

model. In most cases no serious problems will be encountered, but

a little far-sighted planning at this stage can avoid disappointment

later. Taxiing the Seaplane: Perhaps the greatest joy in

seaplane flying is the takeoff and landing surface that water provides.

Most important are facts that takeoffs and landings can always be

into the wind and that the water is much softer than the hard ground.

With a water rudder and with the motor at a medium speed your model

seaplane becomes an "air-boat." It can be taxied from the shore

to a good spot for takeoff and, after landing, it can be taxied

back to the place on the shore where you are standing. "Proto" ground

handling in seaplanes is much easier than in landplanes and can

save a great deal of awkward handling in chase boats or wading in

muddy ponds. This can add greatly to your pleasure. Water

rudders can, and should be, small. A six-foot model will handle

well with a rudder 1/2" high and 1 1/2" long. Unlike air, water

is dense and, therefore, a control surface is much more effective

than air rudders of similar area. The rudder should be small to

minimize the water drag it causes. A balanced rudder with about

1/3 of its area in front of the rudder post is desirable, especially

if you are using low-power servos. If you are using rubber-driven

escapements, it is virtually impossible to make them powerful enough

to drive an underwater rudder. Incidentally, don't let this fact

stop you from trying escapement controlled seaplanes. Once up to

speeds where the air rudder becomes effective, a well designed escapement

con-trolled seaplane will handle well on the water and in the air.

Here again, the Sea-cat is an excellent example. Many of these models

have flown very well as originally designed with escapements.

Taxiing should be done at medium speeds - just short of

getting up in the step. At low speeds steering becomes sloppy and

weathervaning becomes a controlling factor. Therefore, at least

three-position motor control is desirable for effective water handling.

Note that with a well chosen medium speed many seaplanes without

water rudders will do a reasonable job of taxiing. In addition

to the water rudder and motor control, several other factors will

influence a seaplane's water handling characteristics. Since airplanes

with high wings tend to catch the wind easily and will weathercock

or actually capsize when broadside to the wind, they tend to have

the poorest water handling characteristics. With them it is often

impossible to turn it into the wind for takeoff, or to taxi back

to the starting point. Any seaplane pilot who has flown high wing

lightplanes on floats will tell of similar problems. One of the

best light seaplanes is the Colonial Skimmer. This plane has a low

profile when on the water; its propeller is well shielded from spray;

and it has won the praise of many pilots. This airplane should make

an excellent scale model seaplane; the plans from a Berkley kit

would be a good starting point. In any case, seaplane flying

is good fun but to get the most from it, water handling characteristics

should be carefully considered. The potentials in this area alone

make land flying relatively unattractive. Waterproofing:

This is one of the most important factors. The subject can be divided

into two major parts: first, waterproofing the seaplane itself and,

second, protecting the radio equipment. In. a well-designed model

seaplane, equipment protection may not be a problem if the airplane

provides water tight compartments for the equipment. If there is

any question about water reaching the equipment, it is best to wrap

it as much as possible in plastic bags closed with rubber bands

looped around the wires going to each unit. Receivers and batteries

lend themselves to this type of waterproofing. On the other hand,

servos do not since they must be mounted to the airframe and must

have both electrical and mechanical connections. It is therefore,

most desirable to design for "watertight" equipment compartments

- if possible. A major consideration in waterproofing is

the kind of water you will be operating from. Fresh water presents

little difficulty. Radio equipment has been thoroughly immersed

in fresh water, then dried carefully without any apparent deterioration.

Salt water is different and immersion should be avoided. If it does

occur, immediate flushing with good clean fresh water is in order,

followed by careful drying, using forced air if possible. Most vacuum

cleaners can be connected to blow rather than suck air. This is

a handy source of warm air for drying. Salt water will corrode all

common metals, including motors, fasteners, control linkages, landing

gear struts, switches, etc. If you fly from salt water, oil or grease

all exposed metal before and after flying and make sure you wipe

the salt water off metal parts as soon as possible after a flight

is made. Motors appear to cause little difficulty - if you

remember to run them immediately after they have been dunked! The

liberal amount of oil in the fuel provides considerable protection.

Motors start quite easily after being submerged and having ingested

water. A few flips of the propeller and a little shaking will remove

most of the water. Running out a prime or two (inserted through

the exhaust port) will cause the remaining water to be thrown out.

A wet motor sometimes starts better than a hot dry motor since the

wet motor is cool and is less liable to quickly boil-off or evaporate

the methanol in the fuel. Most wet motors will restart quickly,

quickly spitting out water, sputtering a bit and then operating

normally, all within a few seconds.

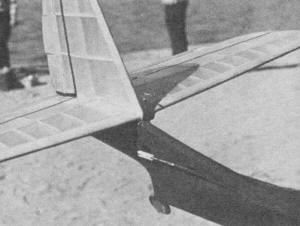

Long nylon pushrod guide keeps water out of fuselage.

|

The most fundamental problem in waterproofing is the plane itself.

The problem is to prevent the airplane from soaking up water. The

immediate effect of absorbing water is to change the balance - particularly

serious when the covering is punctured and water fills some of the

Volume within the structure, such as the Volume between two wing

ribs. And this Volume is quite significant. Because of this

probability it is well to recheck a seaplane's balance several times

during an extended flying session. A secondary problem is that of

drying out the structure (the balsa wood) once it has soaked up

water. Air circulation within the structure is poor. The water and

vapor is trapped, causing the drying process to take a long time.

To lessen the problem seal the inside of the structure, as well

as the outside. The framework should receive at least two coats

of dope, diluted no less than two parts dope to one part thinner.

Spraying will save time, but be sure to apply enough dope to thoroughly

seal the wood. It is desirable to use extra bulkheads in certain

cases to create compartments which are essentially watertight. Typically

this may be done to isolate the rear of a fuselage just in front

of the opening for the elevator. If practical, elevator and wing

openings should be permanently covered for obvious reasons.

As in landplanes the wings and occasionally the elevator of

a seaplane get knocked off. If this happens, the entrance or water

must be prevented. Gasketed covers can be mounted inside the fuselage

at these places, if equipment access through these openings is necessary.

In any case, a gasket should be installed around wing and elevator

openings. Liquid silastic rubber (General Electric "Clear Seal"

for example ) or a closed pore plastic or rubber foam make good

gasket materials.

Silastic

rubber gaskets are formed by applying a generous bead of the material

around the opening, covering it with a layer of Saran Wrap and then

mounting the wing or elevator with elastics, applying enough pressure

to flatten the bead of rubber and making it conform to the surface

of the wing or elevator. The excess rubber that oozes out should

be scraped away immediately; it can be trimmed after curing. but

it takes a real sharp razor edge to do the trick. Most plastic

and rubber foam seems to be the "open pore" type. This simply means

that it acts like a sponge and soaks up water. "Closed pore" sponges

or foams will not soak up liquids. Keep watch for the latter type

of material if you are planning to go the seaplane route. Oil-resistant,

closed-pore, foam-rubber sheet about 1/8" thick is available - if

you can find a place to buy it. This makes fine gaskets when cut

into 1/4" or 3/8" strips. Corners may be mitered and joined with

"Goo" or "Plio-bond." The latter adhesives also may be used to attach

the gasket to one side of the opening. Flat gaskets with

square outlines are desirable, since they can be made easily; and

they seal tightly with a minimum of pressure applied. A fairly simple

method of gasketing hatches in curved surfaces is shown in picture.

Double bulkheads are installed at the front and rear of the section

which will eventually be the hatch. After planking (or covering),

the hatch is cut free and a square gasket seat is installed in the

fuselage and on the bottom of the hatch. There will be slots between

the front and rear of the hatch and the fuselage; these may collect

a little water but this can be quickly removed by pulling the edge

of a rag through the slots. Hatches made in this manner can be held

down using rubber bands and dowels or wire hooks. Openings

required to pass control rods, switch-handle extensions, and similar

devices can best be waterproofed by passing the rod through a fairly

snug piece of metal or plastic tubing for several inches, as it

passes through the skin of the model. Grease may be used in the

tube to assure essentially perfect water seal for all eventualities

short of prolonged submersion. The grease can be omitted in most

cases if corrosion of the rod itself (within the tubing) is not

a problem. If your seaplane has its motor mounted on the

wing, consideration must be given to the installation of the motor

control servo and its leads. It must be possible for the wing to

break loose without breaking leads or leaving an entrance for water.

The recently available nylon tubing/flexible inner cable will allow

new systems to be devised for mounting the servo in the fuselage

and transmitting the control motion via the tube and cable. A break-loose

connection must be included in the tube and cable if this is done.

Another method is to use a slip-clutch-type servo which has an external

amplifier. The servo in this case requires only two leads that may

be connected using snap connections from a couple of old batteries

for a plug and connector that separates with little pull required.

In one case, connections were successfully built into the bottom

of the wing and top of the fuselage. When the wine was mounted,

contact was established via spring loaded fingers in the fuselage

and brass plates on the bottom of the wing. The waterproofing

problem is not half what it seems to be at first glance. The author's

venerable Seacat has now flown for eight years, and only on one

occasion has water entered the hatch in the fuselage. We learned

to fly radio control using this airplane and, needless to say, it

has had many rough landings, including cartwheels, full-speed vertical

dive-ins, nose-overs and others too complicated to describe. In

the one case of leakage, the hatch had not been "dogged" down with

enough rubber bands. CONCLUSIONS: With

small extra effort a well-designed seaplane will fly well. Water

takeoff should occur with ease if the foregoing suggestions are

followed. Briefly, the five points below should be remembered:

- Proper Design of the floats is essential for good takeoffs.

A landplane that flies well can be converted to a seaplane that

flies well. Seaplanes designed for the job will perform best.

- Proper trim of the floats and the airplane overall is essential.

Good design and construction of the float(s) will minimize float

trim problems.

- Rigid float mounts are essential for good takeoffs. Seaplane

floats must be rigidly attached; let the water absorb the landing

and takeoff shocks.

- Sharp chine edges are essential to reducing float drag and

shirring the water cleanly away from the floats.

- Polished float bottoms are essential to reduce float drag

and to let the model slip easily into the air.

- Waterproofing is essential to protect the radio equipment,

to preserve the airplane, and to maintain flight trim.

- A water rudder and motor control is essential to good taxiing

performance which is a major factor in the enjoyment of sea-plane

flying.

Posted May 12, 2013

|