|

While doing research on

rocket-powered gliders and

boost-glide rockets, I ran across the Wombat rocket-boost glider

design and tried to find either a source for buying a kit or for

buying the plans. Neither seem to be available - at least not for

me. When I posted a photo of David Wagner's Wombat, I requested

knowledge of a source for plans and someone send me an old scanned

set. I cleaned them up and posted them here. If you are the

copyright owner and do not wish to have them posted, please let

me know and I will remove them posthaste.

Your Wombat glider has been designed with simplicity, durability

and strength in mind. If you follow the Instructions closely, your

glider will afford many beautiful flights. Read the following Instructions

completely before you start construction. For best results, trace

the fin and wing patterns accurately since the glider flies best

with these particular patterns. You will need the following:

model cement, a hobby knife, fine sandpaper, and two catalogs or

large books. Step 1. Check your kit to identify all parts. You should

have: 1. 1 3" by 9" sheet 3/32"

balsa 2. 2 7/8" by 5" sheet 1/16"

balsa 3. 2 3/4" body tube 4.

1 Balsa nose cone 5. 1

1" x 5" metal sheet (rib) 6. 1

Launching lug 7. 1 Fin pattern

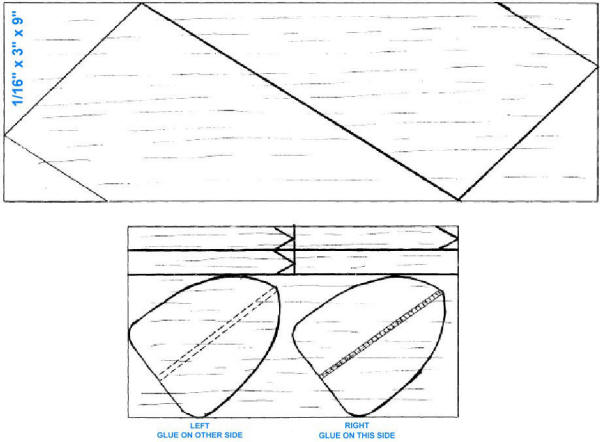

sheet Step 2. Cut the fin patterns from the pattern sheet.

Lay them on the balsa as shown on the sheet and trace them onto

the balsa sheet, being aware of the direction of the grain. Cut

out the wings, stabilizers, pylon sections and glue spreader.

Step 3. Sand all parts so they are the same size as shown on the

patterns. You may wish to round the corners on the pylon pans for

appearance and performance; it is advisable to sand them after gluing

them together as you will be assured a better fit.Step 4.

Glue the pylon parts together and set aside to dry. Next, glue the

wings together as shown in Figure 2. Be sure that the cement rib

(metal sheet) is well centered on the joint between wings. For best

results, apply a coat of glue to one side of the rib and to the

area on the wings where you intend to glue the rib. Let this coat

dry at about 10 minutes before applying a second coat to the wood

and finally gluing all 3 parts together. Put the wing assembly between

two sheets of scrap paper and under several large catalos or books

so that it will dry flat and even. Step 5. While the wing

is drying, you may sand the corners of the pylon until they are

slightly rounded. Using an empty engine casing wrapped with sand-paper,

sand a shallow slot into one side of the pylon so that the curve

of the slot fits around the body rube. (See figure 3). This slot

need not be deep since its only purpose is to increase the gluing

area between tube and pylon. Step 6. Apply a coat of glue

to the slot and to a portion of the body tube of the same size as

the pylon. Let this coat dry about 5 minutes. Apply a second coat

to the pylon slot and glue the pylon to the body tube so that the

blunt end of the pylon is flush with one end of tube. Set aside

to dry. Step 7. When your wing assembly is dry enough to

handle (about 30 minute, after gluing) remove the catalog, or book

and place it on a flat surface. Next, apply a coat of glue to the

shortest edges and let it dry. Meanwhile, apply a similar coat of

glue to the center of the vertical stabilizers along the lines shown

in the fin patterns. Be sure you apply the glue on the correct side

of each stabilizer; you may check by comparing each stabilizer with

the one on the pattern sheet with reference to grain and indicating

notes. After these coats of glue are dry, apply a second

coat to the shortest edges of the wing and glue a single stabilizer

to one edge of me wing. Be sure the pointed end of the stabilizer

fits flush with the front end of the shortest edge of the wing.

Place the wing between the books so that it is held with the attached

stabilizer above the books; that is, place the wing perpendicular

to the table on which you're working. When that stabilizer

is dry, attach the other one in the same way. Allow this assembly

to dry at least 10 minutes before proceeding. Step 8. Apply

a coat of glue to the flat side of the pylon which should now be

glued to me body tube. Let the coat dry for several minutes before

applying a second coat. Glue the pylon tube assembly to the wing

so that the pointed end of the pylon and wing are glued at the same

point. Align the body tube so that it points down the center of

the whole glider. This alignment is very important - if the body

tube is glued off to one side, or is pointing to one side, the rocket

will loop and crash upon takeoff. Step 9. While the tube-wing

assembly is drying, glue the launching lug to the wing about 2½"

to 3" from the front of the wing. Set aside the glider to dry with

the body tube (pod) up. Step 10. When your completed glider

is dry, round the edges of the wing and stabilizers to decrease

drag and turbulence.

Step

11. After the glider is completely dry, take it outdoors or to a

large, open space for flight testing. Hand toss by grasping the

launching lug and throwing it lightly into the wind. If the glider

drifts to one side, sand the bottom of the wing on that side. For

example, if your glider drifts to the right, sand the area behind

the launch lug on the light side. Keep in mind that the right side

when the pod is up is the left side when you flip the glider over

for sanding. If your glider refuses to glide at all, sand the area

behind the launch lug so that the trailing edge of the wing tapers.

If your glider stalls (nose turns up and rocket falls), add a small

amount of weight to the nose cone. Adding or subtracting weight

in a light glider like the Wombat is critical so use pieces of cardboard

glued together to add just the right amount. Step 12 When

your glider is properly trimmed, you may wish to paint it. To obtain

a smooth finish, apply one or two coats of sanding sealer, let dry

and sand with very fine sandpaper between coats. Spray with red-orange

or fluorescent red-orange paint for best visibility. Step

13. After you have completed painting, test-glide your Wombat once

more and add or subtract weight as is necessary. When you are satisfied

with the glide, glue your nose cone in place. You may wish

to alter your Wombat for use in accordance with NAR rules.

To do so, simply cut off the rear 1" of the body tube. Whenever

you fly your glider, tape a 1" wide streamer to the rear of the

engine and wrap it around several times. Tuck the loose end of the

streamer between the pylon and the engine so that it won't flutter

or come loose on takeoff. Be sure to test glide your Wombat after

removing the 1" of body tube since you may have to adjust for the

loss of weight of the body cube. The Wombat should be launched from

a 36" launching rod, Electrical ignition must be used at all times

and it is safest to fly the Wombat when winds are under 20 miles

per hour. If you are using a small area, use only ½A's

and A's. A and B engines will give more spectacular flights but

you stand a greater chance of losing your glider. Good luck and

good flying!

Wombat Printwood Patterns

Posted December 7, 2013

|