|

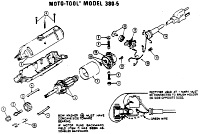

This Dremel Model 370 Moto-Tool is one of my longest-owned

tools. It was bought sometime around 1976. After 40 years of use, it began exhibiting

erratic behavior due to the motor brushes finally having worn down to where they were

not making good contact with the commutator. You can see in the photos how the original

brushes did not wear evenly, although the contact surfaces were clean and not pitted at

all. I decided that given the Moto-Tool's age, it might be a good idea to disassemble

it and do a good cleaning and inspection. This Dremel Model 370 Moto-Tool is one of my longest-owned

tools. It was bought sometime around 1976. After 40 years of use, it began exhibiting

erratic behavior due to the motor brushes finally having worn down to where they were

not making good contact with the commutator. You can see in the photos how the original

brushes did not wear evenly, although the contact surfaces were clean and not pitted at

all. I decided that given the Moto-Tool's age, it might be a good idea to disassemble

it and do a good cleaning and inspection.

Overall, the Dremel was in very good condition. It has always been well cared for and

kept clean and dry. A toothbrush and some isopropyl alcohol did a great job of cleaning

all the balsa and plywood dust off the case and internal parts. Even though it wasn't

really necessary, I let the magnet assembly soak overnight in a jar of

Evapo-Rust. As you can see from the "after" photo, everything looks

almost new.

A light burnishing of the commutators was done with 1200 grit wet/dry sandpaper, followed

by a good alcohol cleaning to make sure there were no residual metal or carbon particles. A light burnishing of the commutators was done with 1200 grit wet/dry sandpaper, followed

by a good alcohol cleaning to make sure there were no residual metal or carbon particles.

Reassembly went easily. The new brushes had to be purchased from an aftermarket manufacturer

in China because Dremel no longer supplies them for the Model 370. These brushes do not

appear to be as high a quality at the originals, so time will tell if they can last four

decades.

After breaking in the brushes with a series of slow-to-fast-to-slow cycles, and allowing

time to cool down in between, the Moto-Tool runs very smoothly and with good torque. The

reconditioning was a total success. I have used the Dremel Moto-Tool few times since,

and it works very nicely.

Posted June 17, 2017

|