|

Here

is the article and plans for the Senior Aero Sport that I electronically

scanned from my purchased copy of the March 1975 American Aircraft

Modeler magazine. You might be able to scale up the image below

if you cannot find suitable plans for sale. Plans for this fine

model were drawn by Mr. Mark Frankel. All copyrights (if any) are

hereby acknowledged. Bipes are beauteous ... they're

dramatically angular, yet subtly curved; antique in mood, but modern

in spirit. They possess an eloquence that is awkwardly graceful.

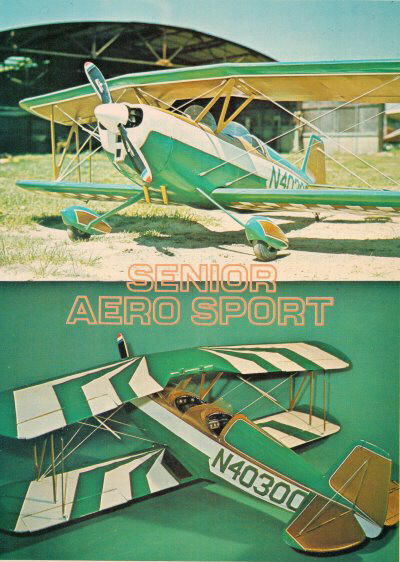

/by Mark Frankel With 67%" of span, the Senior Aero Sport

aims for realistic flight performance-it's like a biwinged Senior

Falcon in the air.

Have

you ever noticed how realistically a really large scale model behaves

in the air? As the model's size increases, its power-to- weight

ratio, wing loading, and other aerodynamic characteristics (such

as Reynold's number) apparently begin to approximate the full-sized

aircraft's. So, in addition to the static appearance of a real plane,

the large scale model presents the added thrill of handling like

the real thing. Have

you ever noticed how realistically a really large scale model behaves

in the air? As the model's size increases, its power-to- weight

ratio, wing loading, and other aerodynamic characteristics (such

as Reynold's number) apparently begin to approximate the full-sized

aircraft's. So, in addition to the static appearance of a real plane,

the large scale model presents the added thrill of handling like

the real thing.

The

Sport Biplane event, as proposed by Jerry Nelson, seems aimed at

capturing some of that realism in Pattern-type competition. The

NSPA rules are clearly intended to simulate the barnstorming stunts

and aerobatics of full-sized aircraft, as opposed to the AMA and

FAI Pattern events, which feature overpowered missiles performing

feats that no man or machine could survive. The

Sport Biplane event, as proposed by Jerry Nelson, seems aimed at

capturing some of that realism in Pattern-type competition. The

NSPA rules are clearly intended to simulate the barnstorming stunts

and aerobatics of full-sized aircraft, as opposed to the AMA and

FAI Pattern events, which feature overpowered missiles performing

feats that no man or machine could survive. The Senior Aero

Sport is an example of a large model that satisfies the philosophy

of the Sport Biplane event. Furthermore, its exact scale outline

allows it to compete in the AMA as well as Stand-off Scale events.

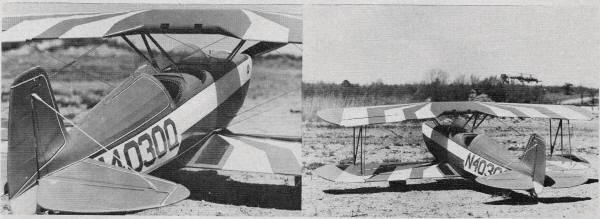

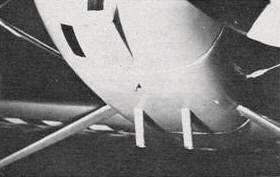

The author taxis the Aero Sport out for another aerobatic

practice session. The shot gives some perspective of the dimensions

of this 10% lb. dream ship.

I considered building the Senior Aero Sport for several years; however,

various obstacles (such as military service) kept me from undertaking

the project. Fortunately, I discovered that the designer of the

full-sized aircraft, Nicholas D'Apuzzo, lives in my general area.

Mr. D'Apuzzo supplied me with three-view drawings of the aircraft

and several photographs of various versions constructed by homebuilders

across the country. He also provided me with a list of completed

Senior Aero Sport projects, including the names and addresses of

the builders. It turned out that two outstanding examples,

Jim rankenfield's N 112JF, and Tom Luckey's N4030Q, were hangared

nearby. An inspection of these aircraft would humble even the most

gifted model builder. Tom Luckey's biplane, the aircraft that I

chose to model, won the "Grand Champion Homebuilt" award at the

1968 EAA International Convention. Jim Frankenfield's airplane,

featuring a beautiful paint scheme, also has won many awards. It

is a very photogenic airplane and, consequently, has been the subject

of many homebuilt aircraft articles. Tom Luckey's N4030Q

is now owned by Alvin Levenson, who hangars it at Zahn's Airport

on Long Island, N.Y. When I visited Mr. Levenson, I found that he

had enhanced its beauty by re-upholstering the interior, adding

Navy squadron insignias to the fin, and chrome-plating the spinner.

Jim Frankenfield's N 112JF is currently based at Executive Airport

in Ft. Lauderdale, Fla.

The paint scheme is dashing, with straight lines playing across

and around curved form.

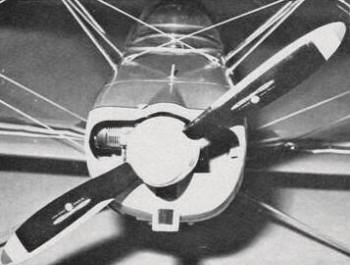

A side-mounted Fox 78 gives plenty of power for the NSPA aerobatic

sequence. The engine is well-disguised in the cavernous cowl.

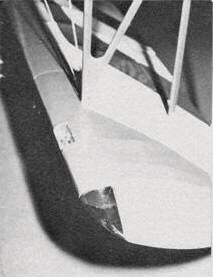

Checkerboard underpainting adds to design's racy appearance.

Detailed cockpits aren't very difficult on a model this size.

They add that final touch to any project.

Of course, there are many other examples of the Senior Aero

Sport across the U.S.-I even heard of a Navy lieutenant who was

building one aboard the USS Roosevelt! I'm sure that a letter to

any owner would bring mounds of photographs and other scale data

for your modeling project. And, a letter to Nicholas D'Apuzzo, 1029

Blue Rock Lane, Blue Bell, Pa., (with a check for $3.00) will get

you a set of three-views, with photographs and a list of all completed

Senior Aero Sports. In addition to these sources, the following

periodicals contain certain information on the Senior Aero Sport:

Sport Flying, February and August, 1970; Flight Digest, fall

1969; Sport Aviation, March, 1961 (this article covers the PJ-260,

single-place version, forerunner of the Senior Aero Sport), and

November, 1968 (Cover Photo of N112JF). If you have any trouble

obtaining scale documentation, please send me a letter in care of

AAM, and I might be able to help. CONSTRUCTION

Construction of the model can begin with any of

the major components: wings, fuselage , or tail surfaces. I'll describe

wing construction first, as it represents the major time investment.

Wings: Begin by cutting forty-four R4, two R3A, two R3, two

R2 and five R1 ribs. Pin and glue the trailing edge stock and the

lower rear spar on the lower TE sheeting. The ribs are then glued

into position, followed by the upper rear spar and sheeting, the

two forward spars, and the 1/8" sub-leading edge [this 1/8" provides

a base for the 1/16" LE sheeting)_ When completely dry,

remove the wing panel from the building board and add the LE sheeting.

The LE of 1/2 x 3/4" soft balsa is then

glued into position and carved to shape. At this point, the ailerons

can be cut from the wing panel. Use an X-acto razor saw with the

stiffener removed; the blade will remain stiff enough to make a

fine cut through the trailing edge. After installing the aileron

control horns, the wing and ailerons are faced with 1/8" balsa.

The 1/8" facing on the wing panel will be resting against the rear

spar. The aileron hinges pass through this facing into the upper

rear spar. The wing tips can be added now, followed by 1/16

x 1/4" balsa cap strips on all ribs not covered by center section

sheeting. After careful sanding, the lower wing panels are ready

for joining. The lower wing has a 1/2°

dihedral angle, or 1/4" elevation under each tip. Epoxy a 1/16"

dihedral brace to both the rear and forward spars. The upper

wing panels are joined through a center section constructed of the

remaining ribs. The 1/8" plywood W1s are epoxied between R2 and

R3. It is important that W1 is glued on the chord line of R2 and

R3, since any deviation will affect the incidence of the upper wing.

Epoxy the outer panels to the center section so that R3 butts against

the first R4 and all four of the panel's spars butt against R2,

and the center section's 5/8 x 1/8" spruce spar fits into the first

two R4s. Now, epoxy scrap blocks of balsa between the spars

and W 1 to bring the spars in contact with W1. Glue maple blocks

to the upper surface of W1 to receive the wing mounting bolts. Use

1/16" sheet balsa to cover the center sections of both wings as

shown on the plans and wrap both wings with fiberglass strips at

the wing panel joints.

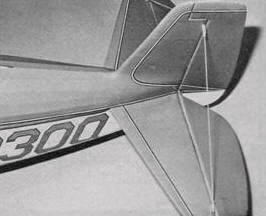

Being a homebuilt project, the Aero Sport-seen from two angles

here-has plenty of scale documentation readily available. The

full-size plane won the EAA's Grand Champion Homebuilt Award.

In some Senior Aero Sports the center section of the upper

wing carries fuel, so it is a bit thicker than the outboard panels.

This can be simulated by adding a layer of 1/8" sheet balsa to the

upper surface of the center section. The bottom of the center section

is left open between R 3 and R 3A to receive the cabane struts.

Note that some of the lower rear spar will have to be trimmed to

allow proper seating of the wing on the cabane struts.

Details, Details, Details

Before covering the wings be sure to epoxy 1/8 x 1/4" spruce

strips to the spars as shown on the plans. These strips serve as

mounts for the Proctor strut brackets (Proctor scale accessory No.

315). Fuselage and Cowl: The basic fuselage

is simply a box structure formed from two built-up sides of % x

%" balsa. A 1/8" plywood doubler is epoxied to the inside of each

fuselage side. This doubler supports the firewall (F 1), the 1/8"

music wire cabane struts, and the landing gear mount. The

basic box structure is formed by gluing F 1 and all cross members

into position between the two sides. Now all formers and stringers

are added; the music wire cabane strut is secured with "J" bolts;

and the 1/4" plywood landing gear mount is epoxied into position.

The next task is to install the fuel tank behind F 1, followed by

the main landing gear which is fabricated from two 3/16" music wire

struts. The gap between the struts is filled with balsa

and fiberglassed to simulate Cessna-type landing gear. I avoided

commercially available sheet metal landing gear because none was

large enough, nor were the struts narrow enough to give a scale

appearance. The 3/16" struts are bolted to the 1/4" plywood mount

with "J" bolts. Note that the fuselage doublers are lined

with 1/2 x 3/4" maple rails on the lower edge. These provide a strong

gluing surface for the 1/4" plywood landing gear mount. Once the

internal work is completed, the forward portion of the fuselage

is sheeted with 1 /8" balsa and a 1" balsa block is added between

F4 and F6. After sanding, the cockpit openings are cut from the

upper sheeting. I formed my cowl over a foam mold. I like

to work with foam, since it carves and sands easily and is relatively

inexpensive. The major disadvantage is that the mold must be destroyed

to free the finished component. To build the Senior Aero Sport's

cowl, simply laminate foam blocks forward of F2, F3, and F4 to match

the approximate shape of the cowl. Three-M's Sprayment is excellent

for laminating foam. Be sure the foam adheres to the fuselage structure

only at F2, F3 and F4. This will allow easy removal by simply cutting

the mold free on that line. If the mold adheres to the doublers

or firewall, it may be impossible to remove in one piece. When shaping

the foam, try to sand it approximately 1/16" undersize in all dimensions

to compensate for the thickness of the fiberglass cloth.

After removing the mold from the fuselage, glue a hardwood strip

to the inside. This "stem" can be mounted to a vise to hold the

mold while you apply the fiberglass cloth. I applied five layers

of medium-weight cloth to the mold, each held in place with 3M Sprayment.

The cloth is then liberally saturated with Hobbypoxy Formula II

and allowed to cure. The mold is removed by dissolving it with lacquer

thinner. The exterior of the cowl is then smoothed by mounting it

on the fuselage and adding a layer of Epoxolite. When the Epoxolite

is sanded smooth, the necessary openings for ventilation can be

cut. Tail Surfaces: The tail surfaces are

formed from light 3/8" sheet balsa. The elevators are joined by

a 1/4" dowel, and 1 /8" masking tape is used under the covering

to simulate ribs on the tail surfaces. The wheel pants are carved

from laminated balsa. The pant is retained on the axle by a Sig

nose wheel steering arm (drilled to receive the 3/16" axle), which

is bolted to the plywood insert on either wheel pant. The entire

wheel pant is covered with fiberglass cloth and coated with finishing

resin or epoxy. The tail wheel strut is fabricated from

.032 K&S aluminum. The "N" struts are built from %" K&S

streamlined tubing. Each strut is cut to length after the wings

are bolted into position. The forward and rear struts fit into Proctor

strut mounting brackets. The diagonal member is epoxied between

the two upright members. When dry, the strut assembly is removed

from the brackets; the joints are fiberglassed and blended smooth

with Epoxolite. Finishing and Rigging:

With the exception of the cowl and wheel pants, my entire airframe

was covered with Silkspun Coverite. Be sure to use an iron that

produces enough heat to effectively seal the Coverite. Once the

model is covered, the rigging can be fitted. Use white elastic cord

for the flying wires. The cord is cut to approximately three-quarters

of the distance between the points of attachment. Goldberg "Mini-Snap"

nylon clevises are knotted on each end of the elastic cord. The

nylon clevises not only simulate the clevises used on full-size

biplanes, but allow quick assembly or breakdown of the rigging.

I

used Du-Bro metal landing gear straps for anchoring the flying wires

to the airplane. The straps are screwed into hardwood in such places

as the "N" strut attachments or they can be inserted into the wood

and epoxied in such places as the fuselage and tail surfaces.

I painted my model with acrylic lacquer plasticized by Southern

R/C Product's Flex-All. Two coats of primer were applied and sanded.

Then the entire airplane was sanded with three coats of white. After

the white had completely dried, I masked for the first trim color,

gold. The checkerboard pattern on the lower flying surfaces

was masked by identically cut squares of vinyl contact paper. Avoid

applying extremely wet coats of lacquer over the contact paper,

as it tends to lift when covered with excess paint. The final color,

green, is followed by the addition of pinstripes - black pinstripes

on all lines where gold meets white, and gold pinstripes where green

meets white. Goldberg's Multi-Stripe tape is recommended. I then

added two coats of clear lacquer to seal the finish. You may

want to try clear Super-Poxy, since it probably will provide a harder

finish. Windshields of .015 clear plastic are attached to

the fuselage with Ambroid Cement. Cockpit detail, such as instrument

panels and seats, can be added at this point. Another advantage

of a large scale model is that the radio gear can be easily hidden

to permit an unencumbered cockpit. I mounted the servos horizontally

under the rear seat. The batteries and receiver were placed just

above the landing gear mount, forward of the front cockpit.

FLYING A reliable radio and engine,

coupled with a warp-free structure and a properly located CG should

ensure a well-flying model. Unfortunately, my first flight was not

trouble-free, since I built my model with scale wing incidence of

20 in both wings. This is far too much incidence for the model,

and the Senior Aero Sport staggered into the air at a dangerously

low airspeed. Even with considerable down elevator, it flew in a

nose-high attitude. After a full stall landing (literally), I realigned

the wing incidence and the Senior Aero Sport has behaved like an

airplane ever since. The plans reflect the current setup of 20 in

the upper wing and 00 in the lower. I am using a Fox .78

with a 14 x 6 Top Flite prop. This power combination is ideal for

effortless takeoffs and large,

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

|