|

As with most of the handyman's

type of magazine of the era, Popular Science features a very broad array

of topics, including full size and model aeroplanes. The May 1968 issue of

Popular Mechanics had plans

for a full-size

homebuilt airplane made of spruce and plywood, using a modified

Volkswagen engine. This June 1941 issue had plans for building a rubber powered

free flight model dubbed the "Minute Man." It is a simple stick and tissue job that

can be built for a few pennies worth (at the time) of balsa, glue, Jap tissue, and

rubber (of course in today's hyperinflated Bidenomics world the price is measured

in dollars). Old timers like myself are familiar with the designer,

Frank

Zaic. He was the founder of the Academy of Model Aeronautics (AMA) in 1936,

an organization which still thrives today. He was also co-founder of

Model Aviation magazine, which

has undergone a myriad of name changes over the years, and is now back to it's original

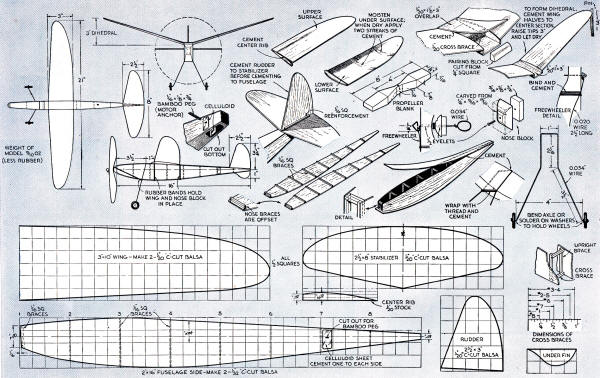

name. Frank's experience as a draftsman for the U.S. Patent Office is apparent in

the quality of his plans, as can be seen below.

All-Balsa Plane Model ... The Minute Man

All materials for this trim little ship cost less than half a

dollar.

By Frank Zaic

Editor of the "Model Aeronautics Year Book."

This little plane, capable of flights of over 2,000 feet, can be built and launched

in less time than is usually required to construct the fuselage of more complicated

models. Its sturdy, simple design is an instructive example of what can be done

with lightweight and quarter-grained ("C" cut) balsa sheets (see P.S.M., Dec. '40,

p. 198).

In selecting the balsa, see that it is light and shows the speckled surface which

identifies "C" grain. Cut the fuselage and wing parts cleanly with a sharp blade

to produce smooth edges. The dimensions of the fuselage cross braces should be taken

from the numbered scale which appears in the drawings. Notice, in the detail of

the nose, how the eight braces are offset for maximum strength. Spread cement carefully

along the full length of the edges when assembling the fuselage. The top and bottom

sheets are trimmed flush with the sides after the cement has hardened.

The wing camber is obtained by moistening the under surface with water, and allowing

the single end rib to extend the camber along each wing. The sheet may at first

tend to curve upward, but will assume the proper downward curve as it dries. When

it is quite dry, apply broad streaks of cement to the underside, as shown in the

drawings. These are important.

Cut the propeller blank from a straight-grained block of balsa, 7/8" by 1 7/8"

by 8".

Form the dihedral angle by elevating wing tips three inches above

the center, and cement on the overlapping strip and fairing block.

Propeller, detachable nose block, "freewheeler," and rubber motor.

The hook on the propeller engages the shaft while motor is under tension, springing

free when the energy of the rubber is exhausted.

Because no model plane is better than its propeller, the builder is urged to

read the instructions given in the article following this one.

The freewheeling device shown in the plans operates in this way: The long hook

is so fastened to the propeller that it normally springs out of contact with the

triangular hook on the motor shaft. After the rubber is wound, the hooks are engaged

by hand. When the motor has been exhausted in flight, the propeller overruns the

shaft, and the long hook springs free, permitting the propeller to turn upon the

shaft. It is important that there be no friction between propeller and shaft once

the hooks are disengaged. A drag at this point may cause the propeller to act as

a rudder during the glide, spoiling the model's performance. In the case of a small

ship such as this, a dragging propeller may even cause it to spin down in a spiral

dive when the rubber is exhausted.

The motor consists of six strands of 1/8" flat rubber. Form it by winding the

rubber over two nails placed 15" apart. Wet the ends, and tie with several knots.

Lubricate the motor with glycerin before pulling it through the fuselage.

The nose block is made of two parts cemented together, its upper face being grooved

for the rubber band which holds it to the fuselage. An eyelet is used for the shaft

bearing. The fuselage shape shown will give the nose block an offset or down thrust

of 1/16". After test flights have been made, or when the motor is to be wound up

for maximum duration (700 turns), the nose block should be given about 1/16" right

thrust. Only experiment will determine exactly the correct amount.

Before flying it under power, test the model's glide. Move the wing back if the

ship stalls, or forward if it tends to dive. The rudder may be warped if a circular

flight is desired. After a smooth, flat glide is obtained, make a test flight with

the motor partly wound, and correct the wing setting if necessary. Once the adjustments

have been made, the ship should readily make flights of more than a minute's duration

in calm air.

Simplicity and sturdiness¢ are the keynotes of this all-balsa design. Study the

plans before starting work.

Minute Man Plans

List of Materials

2 pc. "C" cut balsa 1/32" by 2" by 36" for fuselage

1 pc. "C" cut balsa 1/20" by 3" by 36" for wing and tail

2 pc. hard balsa 1/16" square by 36" for fuselage braces

1 pc. balsa 7/8" by 1 1/8" by 8" for propeller

1 pc. balsa1/4" by 1" by 2" for nose block and fairing block

1 pc. 0.034" piano wire, 24" long, for landing gear

1 pc. 0.020" piano wire, 3" long, for freewheeler

8' rubber strand, 1/8" flat (brown); 1 pair hardwood wheels, 1" diameter; 4 washers,

3/16"; 2 shaft bushings, 1/2'' long; cement, celluloid, bamboo, rubber bands.

Estimated cost: about 35 cents.

Posted September 30, 2023

|