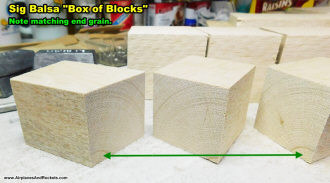

Sig Balsa "Box of Blocks"

Matched balsa block pieces.

Three sections of Sig balsa blocks with matching end grain.

Balsa block sections glued and clamped. Use plenty of

clamping pressure to assure a good joint.

The cost of balsa, like everything else, has been rising significantly since

the COVID-19 "plandemic" hit the world a couple years ago. Along with it the

price of manufactured kits has gone up as well. A simple 1/16" x 3" sheet of

balsa now costs around $2.00 (Sig price). In 2019,

you could get it for $1.13 per the stored page at

Archive.org. That's a 77% increase. Inflation has been at around 8%-9%

(higher in real world numbers) for two years, sapping the life out of everyone.

This has been but one consequence of the government-funded virus released from

the Wuhan lab, and the psychotic reaction by all the world's "leaders."

Being a scratch builder of model airplanes, I frequently watch

e-Bay (very rarely a good deal),

RC Universe,

RC Groups, etc., for

bargains on balsa, but they're getting harder to come by. In fact, you really

need to be careful on e-Bay because you'll often see a pack of maybe ten balsa

sheets for somewhere in the $30 price range, which is $3 per sheet - certainly

no deal.

Balsa blocks have also gotten outrageously expensive. If you have to order a

balsa block online, there is a good chance it will end up being more dense

(i.e., harder and heavier) than desired. Since local hobby shops (LHS's) are

very rare these days, there is seldom an opportunity to go in and look for a

suitable block prior to purchase. Sometimes you want a hard block of balsa,

but that is very rare in my experience. The only option is to use the less

desirable balsa block and hollow it out as much as possible to keep the weight

down.

Being tired of paying $3 for a 2" x 3" x 6" balsa block, I decided to roll

the dice with a "Box

of Blocks" from Sig. No description is provided on the webpage. The 10" x

12" x 15" box arrived as shown in the photo above, crammed full of balsa blocks.

They are stacked on-end with most pieces being 3" - 4" long. About half of them

are what I might buy if given a choice, a quarter are acceptable for use in some

areas with sufficient hollowing, and the remaining quarter are so hard I cannot

push a "T" pin into them. Overall, I'm fairly pleased. The only problem is that

most requirements I have for balsa blocks for wingtips is for lengths 6" - 10"

long. That requires gluing pieces end-to-end. Doing so is no big deal, but

having longer pieces to begin with would be nice.

Upon examining the blocks I noted many have matching surface grain that

looked like they were cut from the same section of balsa. The end grain pattern

confirmed it. After placing the matching pieces end-to-end, they were a perfect

match except for the width of the saw blade. Most of the balsa blocks had at

least one matching piece, with as many as four matches. I could have glued

unmatched blocks together, but then carving and sanding would be made more

difficult due to the abrupt change in grain direction and balsa density.

Since butt-end glue joints are not very strong, I sawed all the to-be-joined

ends at 10° using my bandsaw, then glued (using Sigment) and clamped them,

letting them dry overnight. I would have preferred more like a 15° or 20°

angle, but didn't want to waste that much balsa. Besides, once the joined balsa

blocks are glued to another part of the model airplane structure, they will be

plenty strong. I just need them to be strong enough for rough shaping and

hollowing prior to attaching.

Even with squeezing on a large quantity of Sigment on each of the balsa block

ends and clamping with heavy pressure, almost no excess glue came from the sides

of the blocks. That indicates the very porous end grain easily absorbed all the

glue. The same amount of glue on the end grain of even soft pine wood would have

resulted in a lot of the glue getting squeezed out. Based on this observation,

if I wanted a really strong stand-alone end-grain butt joint for a balsa block, I would

use enough glue to have it squeeze out when being clamped. That will assure a

good saturated penetration of glue into the wood grain.

I now have twenty-six balsa blocks ranging from around 1½" x 2" to 2½" x 6"

that are from 5" to 11" long.

Posted November 19, 2022

(updated from original

post on 1/7/2017)

|