|

A couple years ago I experimented

with adding rudder control to my

Comet Sparky via a radio control system salvaged from an Estes Sky Ranger model.

It used a solenoid actuator mounted on the vertical fin, and the receiver mounted

in the cabin area of the fuselage. A single cell LiPo battery provided power. To

save weight I stripped the components that came with the receiver for motor control.

It worked kind of OK, but the actuator really wasn't powerful enough to more the

rather large rudder with any authority. I vowed to make it better, but have not

had the opportunity. This article from the September/October 1965 edition

of American modeler proves that the idea has been around for a long time. Even in

1965 people were lamenting the disappearance of wide-open spaces for flying free

flight models (unless you live in the Midwest or Southwest deserts). Mr. Phillips'

airborne system boasted a mere 1.3 ounces - a ton by today's standards, but quite

an accomplishment 50 years ago. He even included plans to a custom airplane model

to host the equipment. NASA Engineer Develops Servo-Tab Control

for Rubber-Powered R/C

By W. Hewitt Phillips

The author's son brings model down by gliding

it in circles overhead. No chase!

Solo launching technique demonstrated by

Mr. Phillips. Let the model lift off and then you can take up the transmitter. All

radio flying should be like this!

Many of the old-timers agree that the greatest thrill in modeling is to have

a rubber-powered plane spiral up, hook a thermal and soar off, leading the builder

on a merry cross-country chase, unfortunately, this kind of flying requires the

wide, open spaces, which are rapidly disappearing. Even the use of dethermalizers

and the 3-minute or 5-minute max has not helped the situation much. In a 10-mph

wind, a model flying in neat circles will drift one-half mile in three minutes.

How many city dwellers have a half-mile stretch of field available? And then, there

are always times when the model will head straight down wind. The author

has always dreamed of being able to control one of these high-performance rubber-powered

jobs to keep it flying overhead. With an air-speed of 12 to 15-mph, the average

Wakefield-type or unlimited category rubber-powered model will make headway into

the breeze on any reasonably calm day. Recently, developments in radio control have

progressed to a point where this type of control is practical. As a result, the

local playground can become a flying field. All that is needed is a radio

installation, including batteries, receiver and actuator, weighing less than about

1 1/2 oz. Fortunately, miniature transistorized receivers weighing 3/4-oz or less

are readily available in inexpensive kit form. A pair of the smallest size pen cells

(Eveready No. 912 or equivalent) weighs just under 1/2-oz. These weights leave just

1/4-oz for the actuator. In this article, an actuator weighing less than .07-oz

is described! How can an actuator weighing .07-oz control a model of 3 to

4-ft span? The secret is the use of an old idea from full-scale aircraft, the servo-tab

control. This device was patented in 1922 by

Anton

Flettner, the German, who also invented the rotorship. For this reason, the

device is sometimes called a Flettner tab. As early as 1925, this tab control was

used on airplanes such as a huge old Handley-Page bomber when pilots found that

the barn-door sized rudders were too heavy to move by human muscle power alone.

Today, airplanes such as the DC-6, the Boeing 707 and the DC-8 use servo-tab controls

so that the pilot can move the controls with comfortable forces when flying along

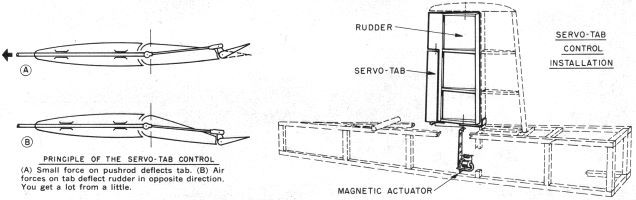

at 300 to 600-mph. The principle of the servo-tab control is that the pilot

(or in the case of a model, the actuator) is connected to a small tab on the trailing

edge of the control surface. As the tab moves, air forces developed on the tab push

the control surface in the opposite direction. Because the tab is so small, it can

be moved with extremely small force. To control a rubber-powered model a

small magnetic actuator, similar in principle to a relay, is connected directly

to the tab control horn by a push-rod. Normally, the tab is held full left by a

small spring, producing right rudder in flight. On transmission of a solid signal,

the actuator pulls the tab full right, producing left rudder. For neutral, a pulsed

signal with equal on and off periods may be used. In practice, however, it is found

that full control in one direction or the other is used most of the time anyway,

so that quite satisfactory control can be obtained with a simple on-off pushbutton

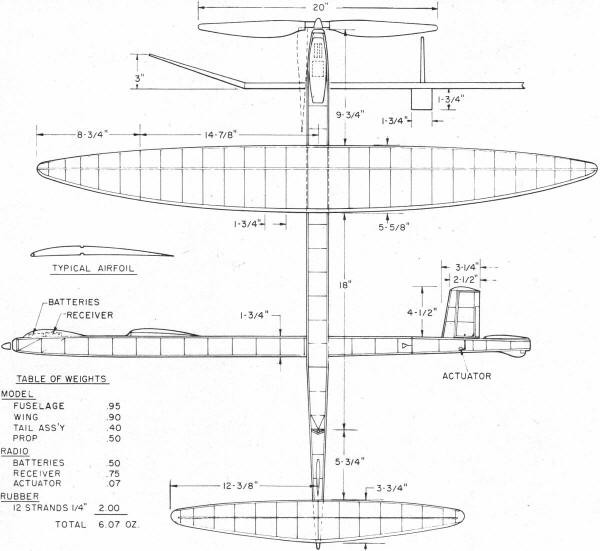

on the transmitter. The rubber-powered model used by the author for the

radio-control installation is fairly conventional. Its design, therefore, is not

emphasized in this article. Instead, the control installation is described in detail.

A three-view drawing of the model and a table of weights is shown. Any conventional

rubber-powered model of this size could readily be converted to R/C by the method

described. The radio receiver and batteries are mounted on top of the fuselage

near the nose in order to move the center of gravity as far forward as possible.

To save the weight of a battery box, the batteries are attached with Scotch Tape

and wired by soldering hookup wire to make the connections. A flea clip is used

as a switch. The magnetic actuator is so light that it may be mounted back in the

tail, eliminating the need for long control linkages which would add friction and

interfere with the rubber motor. To get the power to the actuator, a pair of strands

of No. 40 magnet wire are run from the back along the length of the fuselage. These

wires are preferably glued to the longerons before the fuselage is covered, but

they may be attached on the outside with a coat of dope if it is desired to convert

a completed model to R/C. A pair of light contacts made from bits of brass are soldered

to the wires and glued to the ends of the longerons to make contact with a similar

pair of contacts soldered to the wires in the removable tail section. The No. 40

magnet wire, .003 inches in diameter (almost as thin as a human hair), adds no appreciable

weight to the model, yet has very low resistance compared to the actuator coil itself.

Ordinary hookup wire would be prohibitively heavy for this installation.

(above and below) Practical, inexpensive radio

control of rubber-powered planes is now possible by a system consisting of batteries,

receiver and actuator which weight less than 1.3 oz. Enjoy sport flying from small

fields. Interesting new contest events are proposed.

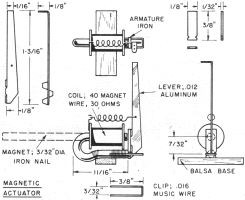

Details of construction of the actuator, tab and linkage are now described. The

small magnetic actuator used to operate the tab is shown. The small electromagnet

may be made by winding wire on a nail of 3/32 inch diameter. The nail should first

be heated to red heat and allowed to cool slowly to soften the iron. Fit celluloid

or cardboard end plates and wind with No. 40 magnet wire, using a hand drill, to

a depth of about 1/16" along a length of 3/8". About 35-ft of the fine wire will.

be required. Finally, bend the back part of the nail around to a U-shape and file

the ends square. The coil should have a resistance of 30 to 35-ohms. The

U-shaped magnet, when energized, attracts a small piece of iron, or armature, in

a manner similar to a relay. Instead of using this armature to operate contacts,

however, it is attached to a light aluminum lever about 1 1/4" long which serves

to magnify the motion. The armature may be made from a piece of soft iron 1/32"

x 1/8" x 3/8". If sheet iron cannot be obtained, a piece of a nail filed flat on

one side may be used. The aluminum extension is attached by binding with nylon thread

and gluing with model cement. Soft .012" sheet aluminum suitable for this and other

aluminum parts in the control system may be obtained from hardware stores in the

form of aluminum flashing. A small clip of .016" music wire keeps the armature in

place as shown. The armature should be a loose fit in the clip. The armature may

be inserted or removed by turning it 90° inside the clip. A small spring, made from

.006" music wire, tends to keep the armature against the magnet. This spring is

mounted oppositely from the spring found in an ordinary relay, which tends to keep

the armature away from magnet. In the present arrangement, the armature is held

away from the magnet by the tab return spring. This return spring overpowers the

spring on the armature. The two springs working against each other serve to take

up any backlash in the tab linkage and hold the armature in the correct position.

If .006 music wire is hard to obtain a piece of 1/32" rubber may be substituted

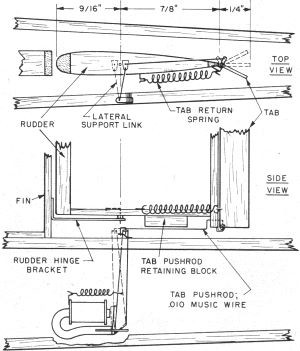

for the spring. The method of hooking up the actuator to the tab and rudder

is shown. A most important detail is the location of the end of the actuator arm

which moves the tab pushrod. With the tab in neutral, this arm must be directly

below the rudder hinge line. With this setup, movement of the rudder will not affect

the tab angle. Full travel of the actuator arm is about 1/16 inch. This motion is

shown exaggerated for clarity. In order to get adequate tab travel of plus and minus

30°, the tab control horn must be quite short, about 1/16". Though the design

of a model for R/C conversion is not critical, some attention must be paid to the

details of the vertical tail and rudder design. The tail size can be quite small

because the radio receiver installation in the nose moves the center of gravity

farther forward than usual. The rudder should be aerodynamically balanced. In other

words, some rudder area should be located ahead of the rudder hinge line to reduce

the moment required to deflect the rudder. In this way, the tab size required to

deflect the rudder may be reduced. Experiments have shown that the location of the

hinge line should be at 1/3 the total rudder chord. A tab chord of 15% of the total

rudder chord and a tab span of 2/3 of the rudder span have proved satisfactory.

Stops should be placed on the fuselage to limit the rudder motion to plus and minus

25°. The rudder, tab and all linkages must be perfectly free from friction.

They should be so free that when the model is tilted from side to side, with the

pushrod disconnected, the tab and rudder will readily flop back and forth due to

their own weight. Once the importance of this low friction is realized, it is not

so hard to obtain as might be thought. Rather than use thread or cloth hinges, common

in most R/C model practice, hinges should be made with .010" music wire shafts fitting

in holes punched in .012" sheet aluminum. Drilling the holes is quite unnecessary.

The holes for the bearings may be punched in with common pins. Small bushings or

washers to separate the moving parts may be made by stripping a short length of

plastic insulation from hookup wire and slicing it into 1/32" lengths with a razor

blade. Care must be taken when covering and doping the model to avoid getting any

dope, paper fibers or glue strings into the "works" to add friction. The

tab is made of 1/32" sheet balsa. Small pieces of .012" sheet aluminum, with holes

punched in them with a common pin, are used as bearings at the top and bottom. The

lower bearing is made integral with the tab horn. The two holes, one for the tab

pushrod and the other for the lower tab bearing, should be 1/16" apart. A small

hook is attached to the tab even with the lower rudder rib to hold the tab return

spring. This spring may be made of .006 music wire or a 1/32" rubber strand may

be substituted. The rudder is of conventional built-up construction. The

tab and rudder hinges should be installed before covering the rudder.

The pushrod to operate the tab is made from .010" music wire. This

size may sound pretty small to conventional R/C builders, but it is plenty strong

for this application and the small diameter contributes to low friction. Pinholes

punched in the tab horn and in the actuator lever to act as bearings can be a sloppy

fit because the springs on the tab and actuator keep the linkage preloaded, thereby

taking up the backlash. The pushrod is simply slipped in place and retained by a

light balsa block glued to the bottom of the rudder. A U-shaped bend in the tab

push-rod will allow adjustments in its length to get exactly the tab motion desired.

The limit of tab motion when the actuator is energized is provided by the

armature hitting the actuator magnet. A thin coat of glue or dope should be applied

to the armature to prevent actual metal-to-metal contact between the two parts,

to prevent them from sticking due to residual magnetism. The limit of tab motion

in the opposite direction is provided by a stop which bears against the hook holding

the tab return spring. An additional wire link, the lateral support link,

is shown. The purpose of this link is to keep the top of the actuator lever from

moving sideways. This link is desirable because the clip at the bottom of the relay

armature does not restrain this lever very effectively against lateral motion.

A careful adjustment and checkout of the completed installation should be

made before attempting a flight. First, the tab pushrod should be adjusted in length

so that, when the magnet coil is energized, the tab deflection is 30° left. No other

travel adjustments are necessary since a stop on the tab limits the deflection to

30° right when the magnet is not energized. The linkage design determines the separation

of the armature from the upper magnet pole when the magnet is not energized. This

separation is about 1/64 inch. This value should not be exceeded, as the ability

of the magnet to "pull in" the armature decreases rapidly as the separation in-creases.

Next, the spring tension on the tab return spring should be adjusted. As

a rough guide or as a starting point for the adjustment, the spring tension may

be balanced against a small weight as follows: Temporarily glue a piece of 1/32"

square balsa, 2 inches long, to the tab to act as a lever for hanging a small weight.

Cut out a piece of the .012" aluminum 1/8" wide and 1/2" long. Lay the tail on its

side and hang this piece of aluminum (about .002 ounces) over the lever. With the

weight 1" from the tab hinge line, the tab should just move to its neutral position

against the tension provided by the combination of armature spring and tab return

spring. Now connect a pair of flashlight batteries producing 3 volts to

the magnet coil. The pull of the magnet should snap the tab to the full-left position.

For a final adjustment of the spring tension, reduce the voltage gradually to 2

volts. The tab should not cease to operate until the voltage drops below about 2

volts. With this setting, the control will continue to function as long as the

battery voltage is sufficient to operate the receiver. A final check of

the completed installation can be performed by holding the rudder in neutral with

a piece of Scotch Tape and keying the transmitter on and off. The tab should snap

smartly from side to side. With the rudder free, the rudder motion will be random,

but in flight the air forces will cause the rudder to flip over instantly when the

tab moves. The procedure for flight adjustment of the model is very similar

to that for any conventional rubber-powered job. Particular care should be taken

to adjust the model to fly straight with rudder in neutral, both power on and in

the glide. In this way, equal control effectiveness for left and right turns will

be available at all times. First, tape the rudder and tab in neutral and check the

glide. If any turn is noted, correct it by warping the wing slightly. Then adjust

for straight flight under power by varying the amount of side thrust. Since

launching a rubber-powered model requires both hands, solo launches present a problem.

The author has found that a satisfactory procedure is to set the transmitter on

the ground, launch the model, then quickly pick up the transmitter and take control

as required. Control of the model in flight comes naturally with a little practice.

A flyer accustomed to gas-powered radio-control jobs will consider the model docile

because of its low speed. To the rubber-powered fan, however, this means of control

offers a world of exciting possibilities. The model may be steered into thermals,

allowed to hang in them or drop out as desired, and be brought down to spot landings.

All this can be done in a field no larger than the average playground. Because

the current drain of the actuator is very small (about 100 milliamps for a 30-ohm

coil) a pair of the smallest pen cells will last for a whole day's flying. To get

a little extra boost in model performance, these pen cells may be sawed in half,

using a jeweler's saw, and the ends covered with a double layer of Saran Wrap bound

on with nylon thread to keep the moisture from evaporating. These half-size cells

weigh only 1/4-oz per pair and still give enough energy for about five flights.

One of the more interesting aspects of the rubber-powered R/C model is its

contest possibilities. These models should not be flown in competition with uncontrolled

models. Such a procedure is certainly contrary to the spirit of the present AMA

rules, even if it is not specifically prohibited. Instead, the rubber-powered R/C

model offers the opportunity for a special type of contest in which all artificial

design restrictions and limitations are removed, and in which the element of luck

is greatly reduced. Consider, for example, a contest for rubber-powered

R/C models in which the rules are as follows: (A) Winner determined by the maximum

endurance (best of three attempts); (B) Flight disqualified if the model fails to

land in a specified 100-ft radius circle. The usual artificial restrictions

such as weight rules or limitations on maximum endurance are completely absent.

A review of the history of outdoor rubber-powered model development shows that in

the early days no restrictions of any kind were imposed, but primitive design and

construction techniques prevented unduly long flights or loss of many models. As

models improved, however, weight rules were imposed, first 1-oz per 50 square inches

and then 2-oz per fifty square inches. This restriction failed to hold endurance

in bounds for very long, but it did end the incentive to make structurally light

models. Finally, as dethermalizers were perfected, the max concept was introduced.

This rule has the objective of preventing out-of-sight flights. As the model designs

improved, the ability of more and more modelers to make maxes as a matter of course

has resulted in all experienced builders being placed on more or less equal terms.

The natural result is more rounds and more flyoffs, until the contest is decided

partly by physical endurance of the modeler and, in some cases, by luck.

How does radio control change this situation? With contest rules of the type

proposed previously, there is no need for the max restriction. The flyer must bring

the model in to a landing near the launch point and is thereby prevented from losing

it. In addition, there is no need for any weight rules, because the wing loading

must be kept high enough for the model to make headway into the wind and because

the radio gear provides an unavoidable "payload" weight. Skill in flying becomes

important, because the model can be allowed to circle in a thermal for a while,

but can never be allowed to drift downwind so far that it cannot glide back to the

launch point. Since thermals do drift with the wind, very long flights are unlikely.

If more emphasis on precision of flying is desired, the rules suggested

previously might be modified such that the endurance in seconds is decreased by

the distance in feet that the model lands from the launch point. With rules such

as these, the modeler is faced with a true test of skill in designing, building

and flying. He may gain an advantage by better aerodynamic or structural design,

more sophisticated or lighter control equipment, and by skill in riding the air

currents. He is no longer placed on a common level with other builders by artificially

imposed restrictions.

Plans for Rubber-Powered R/C Model Airplanes

<click for larger version>

Posted November 13, 2011

|