|

Modern day scale models are

amazingly detailed with functional miniature instruments, control yokes and joysticks

moving in unison with stabilizer, rudder, ailerons, throttle, and others. Access

to relatively inexpensive 3-D printing, laser printers, and laser cutters has greatly

enabled scale modelers. The state of the art has advanced for far that competition

is extremely stiff. Even so, in the 1960's when this "Cockpit Details for the Scale

Model" article appeared in Air Trails magazine, the skill level was quite impressive

given the resources available at the time. This particular subject is an instrument

panel for a Piper J3 Cub, but photos from scale contents of the era showed highly

detailed cockpits for civilian and military aircraft ranging from Cessna 180's to

B-36 bombers and F−86 Saber jet fighters.

See also Instruments

for the Scale Model, from the same issue.

Cockpit Details for the Scale Model

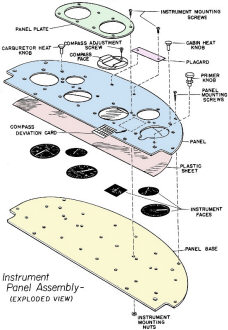

Piper J3 Cub Instrument Panel Assembly (exploded view)

Text and Art by Jim Triggs

For many years we have seen quite an assortment of large R/C planes and flying

scale jobs, most of them gleaming with a fine finish, the product of many hours

of the model-builder's loving patience and painstaking craftsmanship. In almost

every case a closer look at even the best of these models reveals a cockpit woefully

devoid of any detail whatever while others display only the crudest attempt at detailing

the interior of the airplane.

In the case of the average modeler, it is an almost complete lack of information

or data concerning airplane interiors, cockpits, instruments, which prevents him

from including them in a scale model. Other model-makers who may be thoroughly familiar

with the more conventional methods and techniques in putting together a model airplane,

find themselves at a loss to cope with the construction of the many instruments,

dials, knobs, switches, controls, and other gear found in the cabin or cockpit of

even the simplest airplane.

It would seem a shame to lavish hours of hard work on a big R/C or scale plane

that has no discernable inside detail which takes only a small portion of the total

time necessary to build such a model but which makes the ship a real outstanding

job. While it is true that some of the scale radio designs allow little room in

the cabin for excessive detailing, it is still possible to include some in most

cases.

First consideration in building an accurate representation of cabin or cockpit

detail into a scale model is accurate information. While this data is found in many

places, the best source is publications which often publish photos or details of

cockpit arrangements of various aircraft, both military and civil. Such a photograph

will at least give the modeler a partial picture of cockpit detail and panel layout.

The trick is to accumulate enough data to get the whole story.

Piper J3 Cub Instrument Panel.

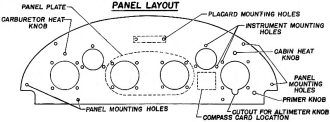

Piper J3 Cub Instrument Panel Layout

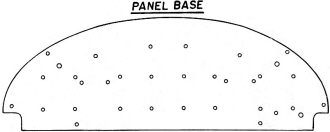

Piper J3 Cub Instrument Panel Base

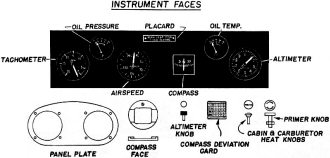

Piper J3 Cub Instrument Faces

Further research may lead the modeler to write to the various aircraft manufacturers

for data. While manufacturers of military airplanes may be hesitant about providing

such information due to security or business considerations, other concerns may

be very happy to provide assistance through their public-relations or advertising

departments. Very fine brochures and catalogs of the private plane manufacturers

are readily available. Most of this literature provides very good information and

photos of the airplane concerned, inside and out. Piper Aircraft Company, for instance,

publishes full color booklets on their Tri-Pacer and Super Cub models which provide

all the information necessary to make a completely detailed interior of either airplane.

Some model-builders have placed their reliance on some of the meager information

provided with the average kit. Far too infrequently will the commercial kit give

any accurate cockpit detail.

In his research, the modeler will soon become familiar with cockpit and instrument

arrangements of various airplanes. It becomes apparent that certain arrangements

are typical regardless of the type of airplane. Note the separate grouping of flight

and engine instruments on the panel. The arrangement technique will often help out

the modeler who is unable to determine the exact position of a turn and bank indicator,

or oil pressure gauge from his data.

In finishing a scale model interior, close. attention to detail and neat workmanship

is essential to a convincing finished product. One of the points most frequently

passed over or ignored in the scale cockpit is the structure of the interior walls

and floor of the cockpit. Most private and commercial airplanes are finished inside

- that is, the bare structure of the airframe itself is covered with upholstery,

headlining, and/or some other material, plastic, leather, etc. In the case of the

military airplane of older vintage, the bare bulkheads, channels, and stringers

of the airframe are usually exposed and visible in the cockpit with the only protection

to the pilot afforded by the outside metal skin or fabric covering of the airplane

itself. On more modern military aircraft, interior structure may vary in construction

detail but are seldom finished or upholstered as is the case with civil planes.

For the model-maker, it is just as important to include this detail as it is to

model the instruments or controls accurately. A little imagination and ingenuity

will provide the materials and techniques to accomplish this phase of the model.

For instance, it will be found that various flock-covered papers, in many colors

will often simulate exactly the types of upholstery used in many private and commercial

airplanes today.

Perhaps more interesting than upholstery will be other inside gear and equipment

contained in the cockpit. The control stick, wheel, rudder and brake pedals, flap

handle, control linkage system (or that part of it which may be visible), throttles,

knobs, switches and radio equipment can be modeled from easily obtained materials

with some ingenuity. While many of these tiny and often intricate items can be built

up in brass or other metals and delicately soldered, there is no reason why they

cannot be made from scrap balsa, heavy paper, or other more easily worked materials

and painted appropriately.

In finishing his cockpit, the modeler should not overlook some of the small details

such as a compass, deviation card, operational placards, safety belts, etc. While

some of these little cards and placards may be so small, especially in any scale

under 2", that any attempt at making legible lettering would be foolish, indication

of such lettering is desirable. A line of tiny dots; spaced as words might be, uniform

and even, will almost convince the viewer that he is seeing lettering, even if it

is too small to read.

Probably the greatest stumbling-block is the instrument panel itself. Assuming

that you have spent some time in research and have adequate pictures and data on

the panel, how do you proceed?

The accompanying drawings show the layout and steps in putting together a really

detailed panel for the Piper J3 Cub. In exact 2" scale, this should fit any Piper

Cub model in this scale with possible small variations in the extreme width or height

of the panel due to the structure of the fuselage. In the older Cubs, the top quarter

of the panel is curved toward the front of the airplane slightly; this curve could

be put into the panel after it was assembled and finished.

First layout the panel, panel base, and panel plate. These parts can be made

of thin balsa or even heavy paper in scales up to 1 1/2". In any scale larger than

2" it would be wise to use thin sheet aluminum or brass for the panel to avoid distortion

or warping. Cut these parts out together so that their edges coincide exactly. Layout

all of the holes in the panel, panel base, and plate. Drill the instrument mounting

holes and holes for knobs with a No. 56 drill (a little less than 1/16"). The holes

for panel mounting screws can be made a little larger, about 1/16", to accommodate

small round head wood screws which can be used to mount the panel to the fuselage

structure later. Clamp the panel, panel base, and plate together, then drill all

three parts at the same time so that all of the holes will be aligned. Layout the

instrument cutout holes carefully and cut them out of the panel. If your panel is

wood, keep the holes perfectly round and with sharp edges. If your panel is aluminum

or brass the holes can be cut out roughly and filed carefully to a perfect round.

Paint the panel and panel plate flat black after all holes are drilled and cutouts

smoothly finished.

Cut the instrument faces out and cement them to the panel base; be sure they

are properly centered under the instrument cutout holes in the panel. The placard

may be cemented to the panel in the proper position and holes punched through for

the mounting screws. The compass deviation card is paper and is likewise cemented

to the panel in the indicated position at the right of the magnetic compass.

A sheet of clear plastic to simulate the glass plates covering the instruments

is sandwiched between the panel base with instrument faces and the panel proper

as shown in the exploded drawing. With these parts held in alignment, the mounting

holes can be punched through the plastic sheet with any sharp tool such as a scriber.

The panel, panel plate, plastic sheet, and panel base are assembled, using short

00-90 machine screws (round headed) through the front of the panel; 00-90 hex nuts

are tightened on the ends of the screws in back of the panel base. These tiny machine

screws can be either brass or steel. If brass, they should be painted flat black,

as is the panel. Steel screws may be left shiny. Screws in these tiny sizes are

available in most hobby shops, as are the small drills described.

The compass face can be built up from thin balsa and a small screw set in to

represent the adjustment screw. Paint this part flat black and cement it into position

in the compass cutout in the panel. Compass face should protrude slightly from the

panel.

Carburetor heat and cabin heat knobs can be made up with short pieces of hardwood

dowel with the large rounded heads made from soft balsa. The shafts of these knobs

should be painted aluminum with the heads painted shiny black. Make an indication

of lettering across the face of the knob. The knobs are glued into the appropriate

holes above the altimeter and tachometer dials.

Altimeter knob is made up as above except that its head is smaller and flat across

its face. Although this knob is knurled in the prototype, this would be all but

invisible in any scale smaller than 2 1/2" or 3". Paint this knob flat black and

glue into position in its hole below the altimeter dial. The head of the knob should

protrude above the face of the panel in the cutout provided.

Primer knob is made up in wood or metal and painted aluminum. The stamped lettering

of the original can be duplicated or at least suggested pretty well with the sharp

point of a fairly hard pencil. Slip a small hex nut on the shaft of this knob and

cement the shaft into its hole on the panel to the right of the altimeter. The nut

on the shaft should be flush against the surface of the panel.

In inserting these knobs into the panel assembly, the 00-90 holes originally

drilled for them may be enlarged to suit the exact diameter of the shafts by using

a small triangular reamer such as is sold in most hobby shops for model railroaders.

Posted September 17, 2022

|