|

Website visitor Rob P. wrote to ask that I scan and post this

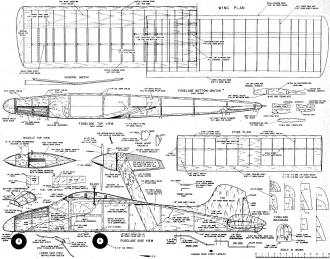

article and plans for Claude McCullough's "Chariot" radio control

model. The 58" wingspan high wing model features a pylon-mounted

.23-size engine. Although the original used rudder-only control,

no doubt Rob will use at least three channels, and maybe even add

ailerons for a fourth. He may even decide to adapt the Chariot to

electric power. Simple stick and sheet balsa construction helps

to make for easy, inexpensive building. Hopefully, Mr. P will

send a photo of his completed Chariot for posting here.

Mac's "Chariot"

By Claude McCullough

President & Contest Board Chairman. Academy of Model Aeronautics

(D.C.)

Just what the doctor ordered for the AMA's new

Pylon Racing Event, this remarkable radio plane is perfect for rudder-only

work

The original "Chariot" was built primarily as a sport flying

model for use at R/C picnic and evening fly-for-fun sessions and

the unusual layout was chosen mainly on the basis of its appeal

as an interesting, out-of-the-rut project. Considering this background,

I was agreeably surprised to find that the design has performance

features which alone make the high thrust line conformation something

for more radio control fans to sample.

Most valuable characteristic is the penetrating ability in a

high wind, something very necessary to successful rudder-only performance.

"Chariot" will stick her nose into a stiff breeze and make headway

when a more conventional job will not.

Next noticeable feature is maneuvering ability with smooth, on-the-track

turns without bouncy entry and pull-out. No design of equivalent

size that I have flown could handle power so well. The prototype

uses a .23 run full-out and I don't doubt that it could manage a

.29 if necessary.

Claude McCullough and his "Chariot." Two-wheel

gear, replaced nose wheel; nacelle changed too

Needless to say, it is a rare day when a prop is broken. Not

that this can be considered a lesser advantage - as any R/C flier

who has to add a half a dozen broken props to a day's fuel and battery

bill can testify.

The prototype model was built from selected hard balsa, carries

copious battery and equipment choices, topped by multiple coats

of dope and at 20-oz-per-sq-ft wing loading can hardly be considered

acrobatic. Still it is evident that a plane built to a lower weight

with light equipment could more than hold its own competitively.

In particular the performance suggests itself as just the ticket

for the new AMA Pylon Racing Event.

Modelers who see the ship for the first time invariably marvel

at the pylon being able to stay in one piece, since on the original

version it is made from three laminations of 1/8" balsa. The secret

is the special rock hard grade from a stock Frank Zaic selected

for me some years ago.

At the annual Iowa R/C picnic I got to thinkering (as is my unfortunate

habit) with previously worked out adjustment and snapped stalled

the ship in under full power. The pylon, then fastened only at the

top and bottom of the cabin, was thrown completely clear of the

ship, but was not damaged at all. In repairs, 1/4" sheet wedges

filled-in to the bulkheads in front and to the rear (as shown on

the plan) were added and no further trouble has been encountered

despite my un-coordinated style of operation, which gives the ship

more than its share of hard knocks.

Because of the certainty that the quality of wood I had is not

commercially available now, plan shows a 1/8" plywood center with

ordinary 1/8" hard balsa outside. This provides a pylon of similar

weight and possibly greater strength with the addition of a more

positive motor anchorage point.

For the average version of the "Chariot" I would suggest a .19

motor. If you incline to heavy batteries and lots of dope, a .23

will be best. For lightweights with small radios a .15 cubic incher

may be fitted but I would not recommend anything smaller.

In construction I made use of one of Frank Zaic's neat aids to

modeldom, the 60" R/C Wing-Stab Kit. This ingenious shortcut comes

with die-cut ribs, shaped leading and trailing edges, etc.; besides

saving construction time is of the usual high quality wood that

has characterized FZ's productions. This item is sold only by mail

and is available from Model Aircraft Co., Box 333, Station D, New

York 3, N. Y. for $3.50 postpaid. If you wish to build your own

wing and stab from stock wood, full details appear on the plans.

In a ship of this type one consideration must be kept in mind.

To keep the C.G. in the proper spot, weight should be concentrated

in the nose and saved wherever possible in the tail. Don't spare

anything forward of the wing. Use the heaviest balsa and plenty

of cement. This has a practical as well as aerodynamic application.

The nose section takes bumps and thumps of ordinary flying that

in a conventional design are mainly absorbed by the motor-firewall

unit, and the extra strength is as necessary as the weight. To the

rear select lightweight wood and go easy on cementing, this section

is not subject to very much strain and will not require additional

strength.

My version used the McNabb 465-mc CR receiver - nice deal for sport

flying because you can get many more flights logged by using the

less crowded band and with little chance of interference. Proportional

pulse is standard as far as I am concerned for rudder only flying

and the results of the "Nats" R/C events give plenty of support

for that preference.

If you prefer another type of control there is ample space for

mounting available in the actuator compartment. Cabin and nose battery

box are both of dimensions that easily accommodate any standard

single channel unit and most small multi-channel outfits. Because

the choice of mounting is so dependent on the receiver and personal

prejudice of the individual constructor, I have not specified any

particular receiver installation-you can easily adapt your favorite

setup.

Fuselage is basically built upon the bottom crutch of 1/4" sq.

balsa, but instead of the usual method of building the crutch first

and then assembling the rest of the body on it, I believe it best

in this case to build two sides over the fuselage side view composed

of just the bottom longeron and the square forward cabin section

- the part on either side of the cabin window. After these have

thoroughly dried, the crutch bottom is completed over the fuselage

top view. Cabin top is completed with 1/4" sq. cross pieces.

Add Formers F-1 through F-9 to the crutch, using a right triangle

to align them correctly. Next step is to plank the bottom of the

crutch with 1/16" sheet balsa - 1/16" plywood being used under the

nose section, as well as in the area where the rear landing gear

is mounted.

Prepare the pylon for assembly by bolting the 1/32" brass motor

mounting brackets to the 1/8" plywood center. The crankcase nuts,

or radial mount adapter nuts if your motor has this type of provision

for radial mounting, are soldered to these brackets so that the

motor may be removed easily at any time. Cement the 1/8" hard balsa

sheet outside pieces on under pressure until very dry. Use hot fuel,

proof cement for this application as well as any other near the

motor nacelle or pylon.

Cement pylon to the fuselage bottom and secure in place at the

top by assembly of the platform pieces P-1, P-2 and P-3. Add the

1/4" sheet fill-in wedges to brace the pylon to F-5 and F-6. Fill

in around the base of the pylon with 1/4" sheet.

Motor nacelle is completed by install-ing 1/8" plywood firewall

and the balsa block cowl and nacelle sections. Top half is left

solid to add rigidity to the motor mounting, bottom half is hollowed

for installation of the fuel tank. This is of necessity rather odd

in shape, but is not difficult to make from brass shim stock.

Carrying the fuel in the nacelle is a recent change in the airplane.

Originally it used a Walker Pressure Tank in the nose compartment

feeding a regulator in the nacelle through several feet of fuel

tubing. Perhaps it was my application and operation of this device

but I got rather erratic results from this long distance pipe line

and switched to direct fuel feed which has given consistent motor

operation. The slightly different nacelle shape is better from an

appearance point of view than the original shape.

Fuselage is prepared for planking by shaping platform pieces

P-1, P-2 and P-3 with a knife to conform to the fuselage contours.

Run a sandpaper block along the crutch and shape it to blend in

smoothly with the change in fuselage shape. This requires an increasing

angle as you move toward the rear section.

Install all of your equipment mountings and make provisions for

control hookup to the rudder at this point. Plank the entire fuselage

with 1/16" sheet balsa and cement the 1/8" sheet fin in place. Leave

the cabin windshield and windows until after covering and decorating.

Compartment cover for the battery section in the nose is built

separately from 1/8" sheet section T-1 through T-7. It is held in

place by a rubber band in hooks in the fuselage side. Nose plywood

bulkhead "F" and the solid block nose are added finally and shaped

to the fuselage contours.

When the ship was first built a tricycle landing gear was used.

A characteristic of the high thrust line layout is a nose-down tendency,

one of the reasons for the good penetrating qualities. This resulted

in rather long takeoff runs however and it was not long before I

had switched to a two-wheel nose gear. There are cynics locally

who say this was another attack of an ailment to which I have at

times succumbed, known as "multiple-wheelitis." But if, you will

not buy a four wheel gear for your version on the basis of takeoff

tracking characteristics then consider the punishment that a short

single nose wheel must absorb. The two-wheel nose gear simply can

take it better.

I prefer the landing gear bolted in place with light aluminum

brackets instead of cemented so they may be easily moved or modified

if you are experimentally inclined.

If you elect to use a Wing-Stab kit there will be little time

needed for this portion of construction since these deals practically

fall together. Since the construction used is simple and straight

forward you will not have any trouble making up duplicates from

the magazine plans if you prefer to do so.

Note that several .different types of ribs are required - you

can modify your rib template accordingly as the proper number of

each are cut.

There are several minor changes from the standard wing-stab kit

that should be noted. The dihedral used was reduced from 3 1/2"

under each tip to 3". This amount has been quite adequate and gives

smoother turn recovery than higher angles.

The solid balsa stab tip of the kit has been replaced with an

endplate of 1/8" sheet balsa. A small fillet of scrap balsa block

is used to blend the cabin front into the wing.

Prototype was covered with red dyed silk and doped with clear

butyrate dope. Decorations are black with silver pin-striping, applied

with a ruling pen, ruler and french curves. Secret of successful

pin-striping with a ruling pen is keeping the pen clean by dipping

frequently in thinner, wipe and refill with fresh dope.

While it is often said that a design flew right off the board,

this can't be said of "Chariot." The first flights revealed what

I already knew by hand balancing - the C.G. was too far back. Moving

it forward by shifting batteries and actuator ahead quickly remedied

this. If you take care to mount everything as far forward as it

can be stowed you should be able to hit the point indicated on the

plans without any trouble. If you can't do it any other way, ballast

the nose block with lead - but this resort will be necessary only

if you have gone overboard building the tail and fuselage rear.

My original used no thrust offset. If any are required it would

be slight right thrust to counteract torque and upthrust if it is

desired to increase the climbing angle. Don't try to increase the

climb by changing the stab incidence unless of course the glide

also shows signs of being too shallow.

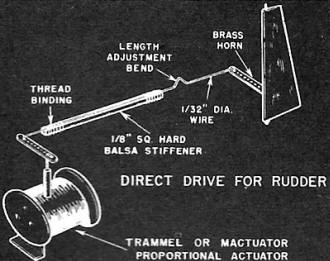

Direct drive for rudder

"Chariot" Bill of Materials

Four pieces 1/4" x 1/4" x 36" balsa fuselage longerons, cabin

frame; (1) 3/16" x 3" x 36 fuselage formers; (1) 1/8" x 2" x 36"

hard pylon outside; (2) 1/8 x 3" x 36" fin, stab endplates, nose

fill-in, compartment top; (5) 1/16" x 3" x 36" fuselage planking;

(1) 1/8" x 1/8" x 36" compartment top stringers; (1) 1/4," x 3"

x 36" platform pieces, fill-in; (1) 1/16" x 1/4" x 18" fuselage

backbone, 3" x 3" x 18" block nacelle, nose.

Following balsa if Wing-Stab kit is not used: (3) 5/16" x 1"

x 36" wing, stab trailing edge stock; (2) 5/8" x 5/8" x 36" wing

leading edge; (5) 1/16" x 3" x 36" wing planking; (1) 7/16" x 1/2"

x 36" stab leading edge; (2) 1/8" x 1/4" x 36" stab spars; (5) 1/4"

x 7 1/16" x& 5/8" x 36" wing spars; (5) 3/32" x 1/4" x 36" wing

cap strips; (1) 1 1/4" x 1 1/4" x 10" wing tips.

Also: 6" x 12" x 1/8" plywood pylon center, firewall and nose

former; 6" x 12" X 1/16" plywood fuselage bottom, landing gear mount;

(1) 18" of 3/32" steel wire wing, tail pegs; (1) 36" of 1/8" steel

wire landing gear; (1) 3" x 3" of 1/32" sheet brass motor mount

brackets; (4) 2 1/2" dia. sponge aluminum hub wheels; (1) 2" aluminum

or plastic spinner. Cement, silk or tissue, clear dope, colored

dope, heavy celluloid sheet, landing gear mounting and motor bracket

bolts.

Full size plans for "Chariot" are on Group Plan

#457A from Hobby Helpers. 770 Hunts Point Avenue, New York 59, New

York (50c).

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted January 11, 2016

|