|

Pendulums

were used way back when to help keep free flight airplanes in a

controlled climb during the powered phase of the flight, and then

in a smooth glide back to terra firma. A weight was suspended from

a wire that pivoted on an axle, and a pushrod was attached to a

movable elevator. If the nose pitched up too much, the pendulum's

inclination to always point toward the center of the Earth would

move the pushrod in a direction to apply a little down elevator,

and vice versa for a downward pitch. I have planned to give it a

try some day, but as with so many other things, I just haven't gotten

around to it. Interestingly, there is still a form of free

flight glider flying in Germany that uses a weather vane arrangement

to control the rudder for keeping the airplane fling in a straight

line. The goal is to record the farthest distance possible. Pendulum

Pete

Author-Designer

Keith Laumer until recently with USAF is now a U.S. Foreign Service

Officer stationed at the American Embassy in Rangoon. Shown is C/L

Pete. Author-Designer

Keith Laumer until recently with USAF is now a U.S. Foreign Service

Officer stationed at the American Embassy in Rangoon. Shown is C/L

Pete. Your model lifts from the runway, eases

into a right turn, builds up speed and the bank tightens until the

wing is almost vertical; a crash seems certain - but not this time

... Pendulum Pete is at the controls! Power cuts, the plane rolls

out into a glide and drifts across the runway as if reluctant to

touch down; Pete is holding her nose up for a three-point landing.

On the next flight, with a little less right rudder, Pete will cruise

in the purposeful manner of a controlled airplane, with steady climb

and smooth approach glide. After a few free flights, a little

variety is in order; so out with Pete's control line wing, add a

set of lines, and you're airborne again in two minutes with a fast

and maneuverable sport job. And if you want to see how Pete will

act with a tricycle gear (or a four-wheeler, just for fun), pop

another gear in place - no tools needed. Pete flies nicely over

land or water with floats installed, coming in on grass without

a scratch. If you've never seen a realistic float model

touch down on water, bounce off. touch again with a dash of spray,

and swing into the wind to wait for a pick - up - you owe it to

yourself to let Pendulum Pete show you how it's done.

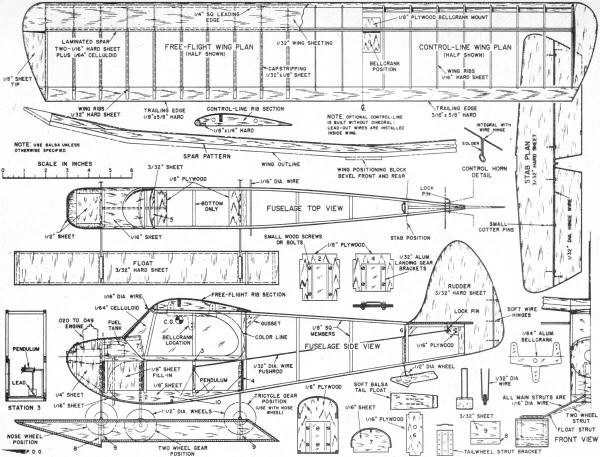

Free Flight Pendulum Pete

Three Wheel Pendulum Pete

Two Wheel Pendulum Pete

Four Wheel Pendulum Pete

Construction? Simple! Fuselage is a simple box with three sheet

balsa parts and four plywood bulkheads. Tail assembly is sheet balsa,

and the two interchangeable wings feature one-piece tips and identical

ribs. Fuselage. Begun by

cutting bulkheads 1, 2 and 4 from 1/8" plywood, # 6 from 1/16" plywood.

Parts 5 and 10 are 1/8" sheet balsa, # 7 from 1/16" sheet balsa.

Aluminum retainer plates for convertible landing gear are formed

by clamping blanks of 1/32" aluminum over a strip of steel 1/16"

x 5/8", tapping with a light hammer. They are trimmed, drilled,

attached to bulkheads 1, 2, 4 and 6. (If fixed L.G. is desired,

simply lace wire to proper bulkhead, using No. 30 linen thread,

and cement binding.) Two sides are laid out using hard 1/8"

sq. balsa. Cut two of each piece, assemble first side over plan

(protect with waxed paper); second side is built directly over first.

While side assemblies are drying, bend pendulum support

from 3/32" brass welding rod to exact size indicated. Pendulum is

soft iron wire (a medium-size paper clip is ideal). Wire is wrapped

around support shaft eight turns. A loop is formed at one end, the

other trimmed to proper length. Lead 1/8" x 3/8" x 3/8" is soldered

to long arm. Washer is soldered to support shaft behind pendulum,

and pendulum retained by wheel collar or by pin inserted through

small hole drilled in shaft end. When thoroughly dry, sides

are removed from plan, sanded smooth before separating, and joined

on bulkheads 2 and 4, with plates attached. The firewall, part 1,

is drilled for radial mount or notched for beams, to fit engine

used. Mounting nuts are glued to rear of firewall or under beams

and retained by strip of balsa glued over them. Firewall is installed;

sides are joined at the rear (note bevel of rear posts). Parts 5

and 7 are assembled, 1/8" sq. cross pieces added. Gussets are glued

in place. Plywood plates are put on at front and rear of cabin roof.

1/16" sheet balsa planking is attached to bottom from bulkhead 1

to cross-member between stations. 2 and 3. First section of fuselage

sides is filled with 1/8" sheet balsa. Interior of tank compartment

is fuel-proofed and No. 1 Perfect Fuel Tank (or equal) installed,

after which add sheet balsa covering. Sheet balsa cowling

is built up, side pieces first, then top and bottom, finally the

nose. Allow rough cowl assembly to dry before shaping with sharp

knife. Entire fuselage should be carefully sanded and coat of clear

fuel proofer applied to planked surfaces. Depending on engine used

cowl may be detached as unit or cut along thrust line so only top

half is removable. Pendulum support is glued in place and

reinforced with strip of nylon glued over wire and to sides of 1/8"

sq. balsa members at station 3. Front and rear wing mounting hooks

of 1/16" wire are added. Entire fuselage, including planked surfaces,

covered with light silkspan, wet, and clear fuel proofed. Tail Assembly. Rudder and elevator are cut

from medium hard 3/32" sheet balsa and sanded to streamlined shape.

Rudder tab is cut from rudder and mounted using soft copper wire.

Movable elevators are cut from stabilizer and elevator hinge and

control horn wire bent from 1/32" piano wire. Locking pin plate

is cut from tin can, soldered to control horn. Small cotter pins

are slipped over hinge wire, and notches to receive them are cut

in elevators - front edges of which are grooved to receive hinge

wire, which is then glued securely. Cotter pins are inserted

in trailing edge of stabilizer. Elevator is clear doped and sanded

smooth. Push rod should be bent to exact length and engaged in elevator

horn before elevator is glued in place on fuselage. With fuselage

in horizontal position elevator should rest horizontally. Pendulum

arm may be bent slightly fore or aft to adjust this neutral setting.

Glue rudder in place. Wing.

Free flight and control line wings employ identical leading

edges, trailing edges, spars. Ribs are basically similar but control

line ribs have two holes for lead-out wires and additional notch

for leading edge reinforcement. For free flight the spar

is built first. Two identical spars are cut out in four pieces each

from hard 1/16" balsa. A full-length spar pattern is cut from celluloid.

One set of spar members is assembled and glued to celluloid; the

other set is glued to other side of celluloid, forming three-lamination

spar with celluloid in center. When spar is completed rib

positions are marked and 24 ribs added. Leading edge of 1/4" sq.

balsa is next assembled over plan, marked, and attached to front

edges of ribs. Trailing edge, of pine or hard balsa, is cracked

to proper dihedral angles and attached to rear ends of ribs. Tips,

cut from 1/8" balsa, are added next and structure sanded preparatory

to planking leading edge. Hard 1/32" balsa is used to cover top

of wing from leading edge back to main spar.

This

planking is carefully cut to size and attached in four pieces. Center

section is covered from leading to trailing edge on both top and

bottom surfaces. 1/32" x 3/32" hard balsa cap strips are installed

to complete wing structure. Cap strips are glued first at leading

edge, then at trailing edge; care must be exercised to ensure their

contact with ribs full length. Entire wing is now carefully sanded.

Construction of control line wing is identical with that

of free flight wing except for additional leading edge stiffener.

It must also be noted that control line wing is flat and employs

one piece leading edge, trailing edge and spar. Top center planking

is not added until bellcrank is put in position. Plate of 1/8" plywood

is installed in center section to receive bellcrank. Lead out wires

are installed inside wing. Positioning blocks, cut from

1/8" sheet balsa to fit inside cabin roof structure, are glued to

underside of both free flight and control line wings. Special

bellcrank is cut from 1/64" aluminum and bent as indicated. Slots

for bellcrank arms are cut in underside of wing's center section.

Make sure controls work freely before covering top of center section

with 1/32" balsa. Wing is covered with light Silkspan, wet, clear

fuel proofed, sanded lightly. Landing Gear.

A complete set of landing gears for Pendulum Pete includes one

nose gear, one main gear (two wheels); a tail wheel, and two two-wheel

gears used together for a four-wheel gear, one being used with the

nose wheel for tricycle gear. In addition, set of floats may be

made and mounted on same struts as four-wheel gear, provided wheels

are secured by collars to enable them to be removed. Floats

are constructed entirely of 3/32" medium hard balsa. Aluminum mounting

fittings are bent from 1/64" aluminum, sandwiched between bulkheads

8 and 9, and 10 and 9, respectively. A small hole should be drilled

through mounting assembly and pin or bolt inserted to secure aluminum

firmly. Completed mounting assemblies are glued to float side. Other

side is added and bottom planks installed. Interior of each

float should receive two coats of fuel-proof dope and all joints

reinforced with glue. Top covering pieces should be sealed with

two coats of fuel proofer before being glued in place. Back plates

are added last, and entire pontoon carefully sanded. Floats are

given a coat of clear fuel proofer and final sanding before covering

with silkspan. Tail float is carved from soft balsa and 1/32" wire

strut glued in place. Finishing.

With all parts fuel proofed and sanded, entire model should

be sprayed with two coats of white fuel-proof dope. When thoroughly

dry, all surfaces should again be sanded lightly. Now for

the windshield. Since no two models are identical, it will be necessary

to make an individual pattern to fit yours. Use a piece of stiff

paper, such as a magazine cover, and after estimating position of

front wing mounting hook, punch a hole and center pattern on mounting

hook. Wrap pattern around sides, mark position of edges with pencil.

Cut out along lines and check fit. When pattern fits perfectly,

place it on sheet of 1/64" celluloid and trace outline with sharp

razor blade; crack and strip off excess. Install windshield, gluing

first at center; then bend around one side of cabin and glue. When

first side is thoroughly dry, glue other. Pendulum

Pete Bill of Materials 1/8" plywood 2" x 9" for

bulkheads, plates; 1/16" plywood 3/4" x 1 1/2", bulkhead; (3) 1/8"

sq. balsa (hard) 36", fuselage; (2) 1/8" x 1/4" balsa (hard) 36"

fuselage, C.L. wing; (1 1/2) 1/4" x 1/4" balsa (med.) 36", L. E.;

(3) 1/32" balsa (hard) 3" x 36", ribs, plank, caps; (1) 1/16" balsa

(hard) 2" x 36", spars, fuselage cover; (2) 3/32" balsa (med.) 3"

x 36", tail assembly, floats; (1) 1/8" balsa (med.) 3" x 15", wing

tips, fuse parts; 1/4" balsa (soft) 2" x 4", cowl sides and bottom;

1/2" balsa (soft) 2" x 4", cowl top and front; 1/8" x 3/4" pine

43", trailing edges; 1/32" aluminum 21/2" x 8", L.G. plates, bellcrank:

1/64" aluminum 1 1/8" x 6", float attach. plates; 1/32" piano wire

36", push rod, elev. hinge, tail gear; 1/16" piano wire 44", L.G.,

wing mounting hooks; 3/32" brass rod 6", pendulum support; 1/32"

soft steel wire 4", pendulum; lead 1/8" x 3/8" x 3/8", pendulum

weight; 1/64" celluloid 10" x 10", windshield; 1/64" celluloid 2

1/2" x 32", spar lamination; light Silkspan 2 sheets; small fuel

line 6"; clear fuel-proof dope 4 oz.; white fuel-proof dope 4 oz.;

colored fuel-proof dope 2 oz.; 6 small cotter pins; hinges; 12 bolts

1/16" x 3/8"; L.G. plates; (1) 1/4 oz. tank (Perfect #1); (7) 1

1/2" wheel (Perfect #34); 1/2" wheel (Perfect #30). Windows

must be masked off and another coat of white sprayed on front half

of fuselage. One-piece mask for windows may be made by tracing pattern

onto tracing paper, covering with tape and cutting out, after which

paper backing can be stripped from tape. A similar mask

should be made to cover entire front portion of model which is to

remain white. Planked portion of wing should be masked off, as well

as sides of floats. Final color finish is sprayed on entire unmasked

portion of fuselage, wing and floats, after which tape is removed

carefully to avoid tearing paper. Decal numerals can be added to

suit individual. Flying. First make

sure model balances as indicated. Then, with elevator lock pin installed,

hand-launch over grass. Correct any nose- or tail-heavy tendencies

by adding weight. When flat glide is achieved, remove locking pin

and try a low-power flight. Slight nose-heaviness will simply cause

model to drop a little more rapidly in the glide, although pendulum

will hold the nose up. Excessive tail-heaviness will cause rapid

up-and-down fluttering of tail. For control line flying three-wheel

gear is preferable to two. Control line wing is installed by first

sliding pendulum off support shaft and disengaging from push rod.

Push rod is then engaged in bell crank and wing attached by rubber

bands, wing positioning block fitting inside cabin roof to key wing

in position. When flying Pendulum Pete with floats installed,

do not attempt to ROW unless water is smooth. However, when hand-launched,

Pete lands easily even in choppy water. Always launch very gently

as a sudden lunge will cause pendulum to swing back and dive the

model into the ground. Full size plans for Pendulum Pete

are on Group No. 1257 from Hobby Helpers, 770 Hunts Point Ave.,

New York 59, N.Y. (35c)

Pendulum Pete

Plans

<click for larger

version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted May 20, 2012

|