|

Materials and methods for free flight

aeromodeling have changed significantly since this "Free Flight Action" column appeared

in the January 1975 issue of American Aircraft Modeler magazine, but the

enthusiasm has not. Carbon fiber tubing now constitutes a large portion of modern

free flight duration model airframes, electronic timers have replaced mechanical

wind-up timers (and even dethermalizer fuses), electric motors have joined (but

not replaced) glow fuel engines, and lighter and stronger covering has supplanted

tissue and/or silkspan and dope. More efficient airfoils, and wing, empennage, and

fuselage planforms combine to produce new record flights in all competitive classes.

Even modern weather detection and forecasting is being used to predict the best

moment for launching. You've come a

long way, baby.

Free Flight Action

Bob Meuser on FF Sport Bob Meuser on FF Sport

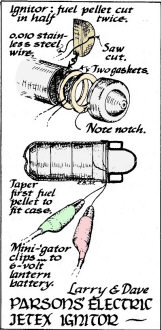

Jetex Breakthrough: Far too often, I've seen an expert fail

three successive times to get his Jetex 150 engine to ignite. We have often pondered

the problem at club meetings. Larry Parsons suggested some sort of electric igniter.

But getting the lead wires through the case was a problem. Some sort of miniature

ceramic feed-through brazed into the sides of the case, a heating element connected

between them, could perhaps provide a solution. But nobody ever did it. Years passed.

Larry didn't give up; there had to be a simple solution.

Whenever I see a beautifully elaborate solution

to a design problem, I know I'm looking at the signs of defeat. Great designs usually

look as though an idiot could have dreamed them up in two minutes. The solution

Larry finally came up with, and his son Dave put into practice, has the right look.

A stainless steel heater wire - nichrome might be better - loops around a notch

in a piece of fuel pellet. No feed-throughs are used; the heater wires are simply

brought out between two thin gaskets which are substituted for the standard gasket.

At a recent contest, Dave's engine ignited every time. He used the same piece of

heater wire all day. Whenever I see a beautifully elaborate solution

to a design problem, I know I'm looking at the signs of defeat. Great designs usually

look as though an idiot could have dreamed them up in two minutes. The solution

Larry finally came up with, and his son Dave put into practice, has the right look.

A stainless steel heater wire - nichrome might be better - loops around a notch

in a piece of fuel pellet. No feed-throughs are used; the heater wires are simply

brought out between two thin gaskets which are substituted for the standard gasket.

At a recent contest, Dave's engine ignited every time. He used the same piece of

heater wire all day.

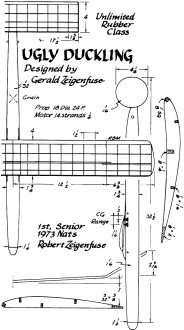

NATS Winning Mini-Unlimited: The

Unlimited Rubber-Powered Model rules permit 300 sq. inches of wing area, and such

models frequently carry nearly half a pound of precious Pirelli rubber. However,

much smaller models often perform disgustingly well. The Ugly Duckling (shown in

the three-view) is one such model, having won the Senior Unlimited Rubber event

at the 1973 NATS for Robert Zeigenfuse, with a score that would have taken second

place in the Open Age Group event. NATS Winning Mini-Unlimited: The

Unlimited Rubber-Powered Model rules permit 300 sq. inches of wing area, and such

models frequently carry nearly half a pound of precious Pirelli rubber. However,

much smaller models often perform disgustingly well. The Ugly Duckling (shown in

the three-view) is one such model, having won the Senior Unlimited Rubber event

at the 1973 NATS for Robert Zeigenfuse, with a score that would have taken second

place in the Open Age Group event.

Designed by Robert's father, Gerald Zeigenfuse, the Ugly Duckling was originally

designed to be flown with old 80-gm. Wakefield motors. The rules were changed. With

twice the rubber of a present-day Wakefield, and less gross weight, the performance

potential of such a plane is obvious; no small-field model is this! The greatest

problem with small unlimiteds is keeping them in sight for the period of a max.

The original model, built by Gerald in 1964, placed first in every contest in which

it was entered.

When Robert got to the age for serious competition and wanted to build an Unlimited,

the Ugly Duckling was the obvious choice. Robert made his NATS-winning flights,

incidentally, using a 1973-vintage Filatti rubber, the kind that barely turned the

prop and was scarcely of sufficient quality for strapping on wings. (The Fillatti

rubber currently sold is as good as good old Pirelli, according to some tests.)

However, it takes more than a well-built model of good designs to win; proper adjustment

is an essential ingredient. Robert spent most of the afternoon preceding the Unlimited

event at the NATS test-flying his model. That took lots of leg-work because of the

fierce wind, but the effort paid off.

Rubber-Powered Speed Contest: Charlie

Sotich, fastest gum-bander in the Midwest, won the IMAC-sponsored speed meet with

a speed of 50.5 mph. That's a hair short of Jim Charlie Sotich's rubber-powered

racer covered the 200 ft. course in 2.7 sec. (50.5 mph] to win the IMAC-sponsored

Speed contest. McCracken's speed made at the 1973 NATS, but Charlie hasn't finished

developing his model yet. Rubber-Powered Speed Contest: Charlie

Sotich, fastest gum-bander in the Midwest, won the IMAC-sponsored speed meet with

a speed of 50.5 mph. That's a hair short of Jim Charlie Sotich's rubber-powered

racer covered the 200 ft. course in 2.7 sec. (50.5 mph] to win the IMAC-sponsored

Speed contest. McCracken's speed made at the 1973 NATS, but Charlie hasn't finished

developing his model yet.

Here are the specs: 24" span, 34.5" fuselage length, 7" plastic prop, 2.78 oz.

gross weight, of which about half is rubber. The lightweight dolly, which uses the

bottoms from foam coffee cups for wheels, falls off after takeoff. CG must be well

forward - 6% of the chord back from the leading edge - to keep the model from zooming

up. Solid balsa wing and tail, and built-up fuselage are employed. The model has

been flown on eight strands of 1/4" Pirelli wound only to two-thirds capacity. Charlie

hasn't broken a prop yet.

"There is still much testing to do," he says. A rubber speed model must be light

- not more than about 4 oz. per 100 sq. inches of wing area - and should have a

prop diameter no larger than one-third of the wingspan. It should be driven by plenty

of rubber.

The Illinois Model Airplane Club meet was held according to the NFFS rules: 200-ft.

course, 100 ft. wide; model must take off from a table; model may not rotate more

than one turn in flight; no dimension may exceed 36".

Charlie has been experimenting with a variety of plastic props, some of uncertain

heritage: one from England, another from France, a 7" Testers prop from an ROG kit,

among others. He suggests that the 9" Peck Polymers prop might be good if cut down

to about 7". He felt that the original solid 3/32" sheet balsa wing was a little

too flexible, and has constructed a light stick-and-tissue wing only 3% thick. We

hope he completes his experiments before the NATS, and shows up with a real sizzler

for the NFFS-sponsored unofficial Rubber-Power Speed event.

Tatone Timer Modification: From

the prolific pen of the old gadgetmaster himself, Bob Hatschek, comes America's

answer to the high price of European multi-function timers. It won't pop up the

tail for dethermalizing (a fuse DT can be used for that) but it will give time-sequenced

actuation of autorudder, autostab, and engine cut. If 1/32" wire is used for the

arms, and the bent ends of the arms are nearly touching, the time delay between

functions is about one-half second. For a longer delay, a knee can be bent into

one arm to better separate the ends. The rudder and stab lines can be hooked up

to the same arm for simultaneous actuation. Tatone Timer Modification: From

the prolific pen of the old gadgetmaster himself, Bob Hatschek, comes America's

answer to the high price of European multi-function timers. It won't pop up the

tail for dethermalizing (a fuse DT can be used for that) but it will give time-sequenced

actuation of autorudder, autostab, and engine cut. If 1/32" wire is used for the

arms, and the bent ends of the arms are nearly touching, the time delay between

functions is about one-half second. For a longer delay, a knee can be bent into

one arm to better separate the ends. The rudder and stab lines can be hooked up

to the same arm for simultaneous actuation.

The lever on the left side goes to the flood-off

device. Those on the right may be connected in either order, depending on whether

the rudder or autostabilizer is to be actuated first. The disk position is shown

just before actuation of the flood-off device. The lever on the left side goes to the flood-off

device. Those on the right may be connected in either order, depending on whether

the rudder or autostabilizer is to be actuated first. The disk position is shown

just before actuation of the flood-off device.

The modification can be made to either a Tick-Off or Flood-Off timer, either

the new models or the old, as the stock faceplate is to be discarded anyway.

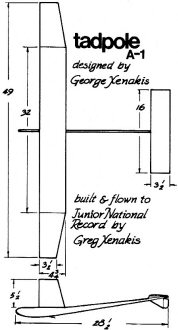

Tadpole: Designed by el maestro George Xenakis to A/1 Towline

Glider specifications, the Tadpole is one of those simple, ugly beasts that has

a special knack for finding thermals. One was flown to first place at the 1974 U.S.

Free Flight Championships by Greg Xenakis, and established a National Record as

well. The wings on the original series of models employed Jedelsky all-sheet construction.

These proved to be too weak, and had to be reinforced with spruce and plywood. The

newer series employs sheet balsa for the rear half of the wing, and built-up construction

for the front half. This promises to be both stronger and stiffer in torsion.

Posted February 11, 2023

|