|

In 1941, model airplane engines invariably were gasoline-driven

ignition systems. As such, onboard batteries were required to light

the spark plug. If you are relatively new to the aeromodeling hobby,

then when you think of an airborne battery, you likely envision

NiCad, NiMH, or Li-Po cells that are relatively compact, lightweight,

and trouble-free. Back in the day, though it could mean anything

from a few carbon cells to a lead-acid storage battery. Early days

of radio control flight routinely had lead-acid batteries to provide

the power needed to run vacuum tube receivers and electromagnetic

actuators. In the case of the Guppie, a 20-second motor run rule

for its competition class allowed a smaller cache of cells to be

carried. Its 6-foot wingspan and classic construction would make

the Guppie a great vintage conversion project using an electric

propulsion systems and R/C.

Build this Swell "Guppie" Gas Job

Because of her profile resemblance to the famed fishbowl pet,

they call her "Guppie." That's not just a name - it's the secret

of her success! Try your hand at this unusual flyer and see for

yourself.

By Martin Powell

Author of "Try This Orbit Gas Buggy."

An outstanding feature of this fine flyer is

its deep belly. Additional side area presented by the odd shaped

fuselage prevents the ship from going into the dreaded spiral "coupe

de grace."

Because model builders persist in flying their gas jobs in any

kind of weather, the tendency prevails to build rugged ships, despite

added weight. It's quite a thrill to watch your gassy battle inclement

weather and yet have the assurance that a hot landing won't result

in its winding up like a ball of wool. But how about that same ship

sent aloft on a calm day? The added weight displays itself with

telling effect. Its glide would probably resemble the descending

angle of an express elevator during the rush hour - straight down,

full car!

Probably after witnessing such a performance, you desired to

build a gas job which would combine a light but rugged structure

and at the same time possess gliding characteristics that almost

defy Newton's law. Well, fellow modelers, meet the "Guppie." With

due modesty, the author claims this is the ship that almost does

the defying!

Among the many features of this unique craft is its deep belly.

During a sideslip the model will actually fly on the area presented

by the odd shaped body and thus prevent the dreaded spiral dive

which invariably ends up you know where. Also, the deep belly enables

the model to take-off in flying position, thereby shortening the

take-off run immeasurably. Now that we must fly on the 20 second

motor run rule, the importance of the foregoing cannot be underestimated

in the least.

The "Guppie" has been designed to operate with either 1/5 or

1/6 h.p. engines. For accuracy in construction and alignment, enlarge

the plans for each part in full scale and work out such sections

on a table or board.

Fuselage and Wing Mount

The fuselage structure is rather unusual, inasmuch as its cross

section changes from rectangular at the firewall to triangular at

section "A-A" and from that point out.

Two fuselage sides are built by pinning down longerons for the

upper and lower portion. The lower longeron is cut off at section

"A-A" while the top longeron extends to the extreme end. Upright

and diagonal members are cemented in place from the firewall to

section "A-A." To assemble, cement the tops of the longerons together

at the rear end also at section "A-A" on the bottom. When thoroughly

dried, the firewall, cross pieces, and fuselage bulkhead are cemented

as indicated on Plate 1.

A third longeron, which forms the triangle section, is cemented

at section "A-A" and held in place by the uprights and diagonals.

Two cross piece retainers cemented above and below the longeron

are shown in their respective position on Plate 1. Cement all joints

generously and allow plenty of time to harden.

The metal wing mount is bent to shape from 1/16" dia. music wire

to the design shown in the front view drawing on Plate 1. The perspective

view on Plate 4 shows how a tin plate is placed upon the wire frame

mount and soldered. Imbed the wire prongs of the mount into the

fuselage sides as shown in the front view and cement securely.

Motor Mount and Landing Gear

The motor mount is of the simple beam-type, extending through

the firewall and the balsa bulkhead directly behind it. Angular

supports for the mounts are cemented to the underside of the beams

- not nailed. Use cement generously around all the joining parts.

The rear wing mounts are shaped from sheet balsa and are cemented

to the top longerons, as shown on Plate 1. A cross piece extending

between the undersides of the top longeron holds the rear wing hook,

which is shaped from 1/16" wire. A single former made up in three

sections is cemented directly over the firewall. Its stringers gradually

diminish and are glued flush to the first cross piece directly behind

the firewall. The sheet balsa fill-in is made up of sections fitted

flush between the uprights and diagonals.

Music wire of 1/8" diameter forms the single wheel landing gear

support. The design in the front view drawing on Plate 1 shows how

securely it may be bound to the firewall with either soft copper

wire or strong thread. Tiny holes bored at intervals in the firewall

allow the thread or wire to pass through and thus hold the landing

gear with great strength. Cover the entire portion with cement and

allow several hours to dry. The rear skid is shaped into a hook

from spring steel inserted upward into the lower longeron and cemented

in that position permanently. The skid, in the position just described,

heightens the angle of the take-off which thereby shortens the run.

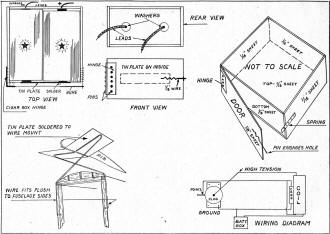

Battery Compartment

The battery box is made from the drawings shown in full scale

on Plate 4. The unit is composed entirely of balsa. Be sure that

when the batteries are inserted they make full contact at all times.

Cement the box to a 1/8" balsa sheet platform. The portion of

the underside of the fuselage between the rear of the firewall and

the balsa bulkhead is filled with this slab. This piece is mounted

on pin hinges which allow the platform to flap open and downward.

The hinges are situated at the forward end. After the battery box

is completed with the ignition leads extending through holes in

the firewall, coat the underside of the box with plenty of cement

and press firmly to the door-platform.

When the cement dries and the platform is swung up and locked

into position, the effect will be exactly as shown in the side view

of the fuselage drawing on Plate 1. A sheet of balsa fill-in of

3/32" thickness is cemented on both sides of the fuselage as shown.

This provides additional strength and takes up the stress exerted

by the torque of the propeller. The coil and condenser are mounted

with any type of wire fittings to hold them securely.

Wing and Tails

Careful plotting and trimming of the ribs assures a balanced wing.

The leading edge is made by inserting a hard balsa strip, 1/4" sq.,

in the notches and cemented at the required angle. Later, it is

rounded off to conform with the shape of the airfoil section. The

wing tips are made up in a series of parts which must fit flush.

Aft of the No.1 wing spar the trailing edge is tapered as shown.

Each half wing is joined together and held fast by cementing

plywood tie plates in the manner shown in the perspective sketch

on Plate 2. From the center rib outward, on each side of the next

rib, 1/16" sheet balsa is cemented. A small section on the underside

of the wing is covered with sheet balsa as indicated on the wing

plan, Plate 2. The entire wing structure is covered with bamboo

paper, water sprayed, and doped three times.

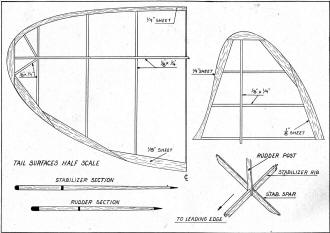

Tail surface parts are of simple design and construction. The

stabilizer is made in one unit, rounded in front and tapered at

the rear. The rudder is put together in the same manner as the stabilizer,

using the materials specified. Both units are covered with bamboo

paper, water sprayed, and doped three times. The perspective sketch

shows the manner in which the rudder post is notched to fit the

middle rib of the stabilizer. Cement this section securely.

Here's Marty Powell with his Brown-powered, single

wheel "Guppie." The ship, which may be flown with any 1/5 or 1/6

h.p. engine, is covered entirely with bamboo paper. Construction

is rugged, yet light.

Assembly and Flying

Before covering the body, attach the 1/8" dia. dowel in the position

shown. The fuselage is covered, one side at a time, with plain bamboo

paper and is then water sprayed and doped.

Attach your air wheel and solder tin washers in place to prevent

the wheels from having too much side play. A wire hook cemented

at the extreme end of the fuselage assists in holding the tail surfaces

down by means of rubber strands extending between the dowel and

the hook. The wing is placed on the metal plate. Rubber strands

extending from the front hook, across the top of the wing, and to

the rear hook holds the wing in position.

Make it a point to always keep fresh rubber bands handy for use

on the wing and tail surfaces. Don't try stretching the bands too

tight when fastening the surfaces. Under such stress the bands may

give way in mid-air.

Painting your model is, of course, optional. Inasmuch as the

"Guppie" is by no great shakes a show-off model, the matter of doping

it up like a Technicolor production is unadvisable. As mentioned

before, weight is the biggest factor in gas job construction. So

wherever fractions of an ounce can be eliminated, the better the

endurance possibilities.

Because of the simplicity of the construction of the "Guppie,"

many modelers will probably attempt to build this ship as their

initial effort. The writer in that case, with your kind indulgence,

is offering some good advice as to the proper method of handling

gas jobs.

Use ordinary precautions before test hopping and endeavor to

obtain the longest glide possible. The most important phase is in

getting the proper adjustment of the surfaces.

Under no circumstances attempt to fly the ship when the wind

is blowing up hard. Simply because you've seen a model climb rapidly

in the face of a stiff wind is no reason to assume that a craft

with more power than an ordinary rubber job will do twice as good.

Choose a calm day for the first test flights. Pour just enough

fuel in the tank for a few seconds flying. If your ship is equipped

with a timer the fuel allotment may be greater, so it won't be necessary

to refill too many times.

Spin the prop, and when the motor starts revving adjust the needle

valve for smooth running.

Face the ship into the wind, open the throttle wide out, and

with a slight shove send the ship on its way.

Bill of Materials

Six strips 1/8" by 1/4" by 36" for lower longerons and cross

braces

Five sheets 1/16" by 2" by 36" for wing ribs

Four strips 1/8" by 1/4" by 36" for ribs in tail surfaces

Two strips 1/4" by 1/4" by 36" for the leading edges

Two strips 1/8" by 1/4" by 60" for fuselage longerons

Two strips 1/4" by 3/4" by 36" for wing spars

Two strips 18" by 1/4" by 36" for rear spars

Two strips 5/16" by 1 1/2" by 36" for trailing edges

One strip 1/8" by 1/4" by 36" for spars in elevator and rudder

One strip of sheet 1/8" by 2" by 36" for wing tips

One strip 1/4" by 5/8" by 36" for motor mount; hard pine

One sheet 1/4" by 2" by 36" for leading edges

One sheet 1/8" by 2" by 36" for trailing edges

One length of 1/16" dia. wire for hooks, length of 1/8" dia.

wire for landing gear, one 4 1/2" dia. air wheel, five sheets of

bamboo paper, tin for wing mount, one length 1/8" dia. dowel, dope,

cement, pins and complete soldering equipment.

Guppie Free Flight Gas Plans

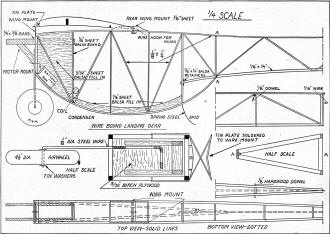

(plate 1)

Guppie Free Flight Gas Plans

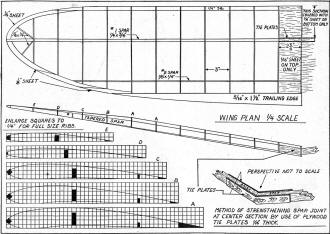

(plate 2)

Guppie Free Flight Gas Plans

(plate 3)

Guppie Free Flight Gas Plans

(plate 4)

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted August 1, 2015

|