|

Many thanks to website visitor Bob Balsie, who graciously offered

to scan this article (with many more to come)

from his collection of Young Men magazine. The front page

tag line above the title proclaims:

"Now!

'Air Trails Hobbies for Young Men' Expands into Young Men • Hobbies • Aviation • Careers"

The final issue of Air Trails - Hobbies for Young Men

was October 1955, so this November 1955 edition of Young Men

- Hobbies, Aviation, Careers was the first in a series that

ran for 13 months. "Now!

'Air Trails Hobbies for Young Men' Expands into Young Men • Hobbies • Aviation • Careers"

The final issue of Air Trails - Hobbies for Young Men

was October 1955, so this November 1955 edition of Young Men

- Hobbies, Aviation, Careers was the first in a series that

ran for 13 months.

Two things caught my attention here. First it that the article

is Part VIII, which means the previous seven were printed in

Air Trails. Second is the photo of Claude McCullough of Ottumwa,

Iowa. Ottumwa is the town from which M.A.S.H.'s

Radar O'Reilly hearkened.

How Construction Affects the Finish

Correct building techniques for any model project can mean an

easier, better finishing job; Paul tells how.

By Paul E. Del Gatto

San Francisco's John Talon turned out this magnificent

Meyers 145; took 2nd in 1955 Nationals' control line flying scale.

So far in this series on how to finish models you've heard from

some very well informed and experienced model builders. But little

emphasis has been placed on some of the general construction techniques

which directly or indirectly influence the finish of a model.

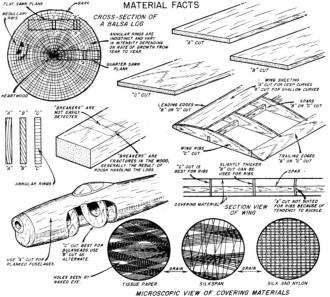

Some facts about the materials used come in handy for anyone

interested in building better looking models.

Balsa wood, our main construction material, is one of the most

difficult of wood surfaces when it comes to applying a good finish.

Couple this fact with the knowledge that balsa wood is cut several

ways for varying degrees of strength, flexibility and weight, and

the need for knowing how to select balsa becomes very apparent.

Look at the cross-section sketch of a balsa log. Note how it

is cut. To begin with any log that is sawed from the center outward

is known as a "quarter sawn" plank. Taking this plank and cutting

it into sheets will yield balsa which in model lingo is referred

to as an "A" cut. This type of sheet is most easily identified by

its flexibility and velvety feeling, and it is best used for planking

large areas such as the wing and stab leading edge surfaces or for

fuselages.

Logs that are sawn approximately tangent to the annular rings

are often referred to as a "tangent slash" or more commonly as a

"flat sawn" plank. Cutting sheets from this plank will yield "C"

cut balsa wood and an intermediary cut referred to as a "B" cut.

"C" cut sheets are instantly recognized by their speckled appearance

and exceptional stiffness, a quality which makes a "C" cut sheet

very valuable to a model builder. This stiffness is the result of

the laminated quality of the sheet due to the perpendicularity of

the annular rings.

Your "B" cut sheet is an intermediary cut between the "A" and

the "C" cuts which has its annular rings running diagonally, rather

than perpendicularly or tangent to the sheet. The "C" cut is best

for most model use where strength and rigidity are required. However,

"C" cut represents the smallest percentage yield of all the cuts

which can be obtained from a log. When "C" cut balsa is not available,

then use a "B" cut of slightly greater thickness to compensate for

the relatively lower stiffness.

Claude McCullough of Ottumwa, Iowa, and new R/C,

4-wheeled Nats entry. A-1 finish.

Because of the spongy cellular structure of balsa it is subject

to "breakers." "Breakers" are cracks or fractures at right angles

to the grain which weaken the wood to a great extent. The bad part

about them is that they are not easily detected until the wood actually

breaks. Manhandling of the rough logs at the mill is the chief cause

of breakers.

Another interesting quality of balsa is its great strength under

direct compression. Rubber-powered model builders are perhaps more

keenly aware of this because of the extensive use of 1/8" sq. longerons

to produce a light structure, yet one strong enough to house a motor

of up to perhaps twenty strands of 1/4" flat rubber. (Cross bracing

balsa, diagonals and paper covering all serve to keep the longerons

in direct compression, to absorb the load of the very powerful rubber

motor.)

Thus the strength of balsa wood is determined to a large extent

by the method of cutting used. Also a determinant of strength is

the weight of balsa for each cubic foot. The average weight of balsa

logs is 12 to 15 pounds per cubic foot; for identical cuts, wood

that is lighter would be less strong and wood that is heavier would

be stronger. Indoor model builders use balsa wood that may weigh

as little as 4 lbs/cubic foot.

It is best to buy balsa wood when the most select cuts and light

weight grades are available to you at the hobby shops you deal with

and then store it at home for future use. This way, when you require

something special you do not have to settle for something which

isn't ideally suited to your needs.

Note all the attention Tatone's Meyers model

receives from photogs at '55 Nats!

Besides balsa wood, the various covering materials used on all

types of models are well worth your attention. Covering represents

the final stage in the model's construction and knowing how to cover

and what material to use under varying circumstances is a "must."

Materials generally employed are tissue paper, light weight and

heavy weight Silkspan, silk and nylon. All these materials are porous

to varying degrees and this is one of the main reasons why doping

is required after the covering has been applied to a model frame.

If we were to examine a piece of each material under a microscope

we would notice that all the materials have a "grain" direction.

This grain direction is important for it serves as a guide to the

correct application of a covering material to either a frame or

solid wood surface.

Of the covering materials generally used tissue paper is the

most difficult to apply for several reasons. To begin with it can

only be applied dry because it lacks the "body" of the other materials

and when moistened tends to fall apart. Then too, its shrinking

qualities do not lend themselves very well in areas where uneven

shrinking is required. Round fuselages, curved wing planforms, wing-tips

and fillets are generally covered with one of the other materials

unless lightness is a serious determining factor in the model's

construction.

This particular advantage of light weight and the fact that an

airtight smooth dope finish can be achieved with fewer coats than

with the other materials makes tissue paper popular with rubber-powered

and small free-flight gas model plane builders. The disadvantages

possessed by tissue paper can be offset a great deal by exercising

particular care on sharply curved areas.

Material Facts

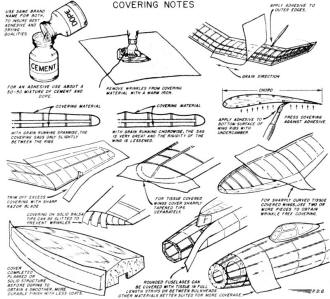

When applying covering to a wing we generally have two surface

areas to cover: an upper and lower wing curvature. Prior to covering

prepare an adhesive of approximately a 50-50 mixture of cement and

dope. With a warm iron (not too hot) press out any wrinkles that

may have been put in the covering material through folding or mishandling.

Whether you cover the top of the wing or the bottom of the wing

first or one panel at a time makes little difference.

Beginning at the wing center joint and covering just one wing panel

at a time, apply the adhesive only to the outer edges of the wing

panel and wing joint for several rib stations and lay the covering

on with the grain running in the same direction (parallel) as the

leading and trailing edges of the wing. Pull the covering taut in

all directions until all the wrinkles have been removed. Then follow

the same procedure until the entire wing panel has been completed.

Remove the excess covering material with a sharp razor blade.

When covering flat surfaces such as fuselage sides, the entire

side can be covered with one whole sheet providing the covering

material is sufficiently long. However, curved fuselage sides must

be covered in smaller sections to minimize wrinkles. If tissue paper

is the covering material use only one full-length strip or do one

bulkhead section width at a time; for Silkspan, silk or nylon the

area covered can be doubled and sometimes tripled.

Silkspan differs in that the main fibers intersect each other

in clusters running diagonally with the grain, but they are more

widely dispersed and held together by a loosely woven arrangement

of fibers running against the grain. These differences explain its

better shrinking qualities; the stronger fibers enable Silkspan

to be applied wet to a model.

Silk and nylon are entirely different in structure from either

tissue paper or Silkspan and are the most desirable of all the finishing

materials to use from the viewpoint of strength and covering qualities.

The fibers of silk and nylon are uniformly arranged and perpendicular

to each other; the grain is determined solely by the closer spacing

of the fibers in one direction than the other. Another interesting

feature is that the fibers go over and under one another. On curved

fuselages or pylons it is almost always possible to cover a whole

side at once with silk or nylon, and it can be applied wet for maximum

flexibility of use.

Covering Notes

Posted October 10, 2015

|