|

Website visitor Joe S. ,of the great

state of Texas, wrote asking me to post this article on the Grumman Ag-Cat biplane

crop duster. According to Joe, "In the 70's I worked for Grumman as a design engineer

located at the Schweizer Aircraft plant at the Chemung County Airport near

Elmira New York. I actually grew up in Elmira. For Grumman, I worked on the

design of the Pratt & Whitney PT6-15AG engine installation for the

G-164D Turbo Ag-Cat."

It's easy to see why he has such an interest in the airplane.

Grumman's "Ag-Cat" Proves Perfect Subject For Control Line Scale

Builders

By Paul J. Palanek

Big Ag·Cat with 450 hp engine totes

2,100·lb payloads using Swathmaster chemical dispenser made by Transland Aircraft,

Torrance, Calif. 220 hp Ag·Cat takes 1,600· pounds.

Grumman agricultural bipe with dummy

engine and scale prop.

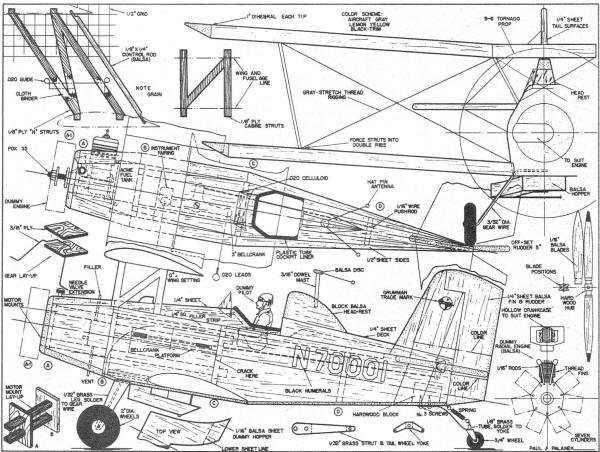

AG·CAT BILL OF MATERIAL (Medium Grade Balsa unless otherwise

specified)

One piece 1/2" x 4" x 36" for Fuselage sides; (1) 1/4" x 2" x 36" for Fuselage

deck; (1) 1/4" x 3" x 36" for Fuselage formers; (3) 1/8" x 2" x 36" for Wing ribs,

fuselage bottom; (2) 1/4" x 1/4" x 36" for Fuselage filler strip; (3) 1/4" x 1/8"

x 36" for Wing spars; (2) 3/4" x 3/4" x 36" for Wing leading edge; (2) 1/16" x 4"

x 36" for Wing bottom; (2) 1/16 x 3" x 36" for Wing top; (2) 1/16" x 2" x 36" for

Wing top; 1" x 1-1/2" x 24" block for Wing tips; 3/8" x 5/8" x 24" Hardwood for

Engine mounts; 3/16" x 5" x 24" Plywood for Formers, bellcrank platform, gear reinforcements;

1/8" x 4" x 16" Plywood for "N" struts cabane struts; Scrap block balsa for Dummy

engine and scale prop.

Misc. items - 3" bellcrank; Acme fuel tank; wheels; 1/16" and 1/32" dia.

wire; nuts and bolts; sheet brass; solder; cement; clear and colored dopes; Silkspan;

stretch thread rigging; large Veco horn; dummy pilot; decals; .29 engine; and 9-6

Tornado prop.

Wildcat, Hellcat, Panther, Cougar, Tiger and now, the Ag-Cat crop dusting bipe by

Grumman Aircraft. Like its predecessors it is a fighter-a fighter of agricultural

pests.

From the ground up the Cat is designed for crop spraying or dusting. It incorporates

a number of unusual features. For one thing, the plane will take half a dozen different

engines in the 200 to the 450 h.p. range. The choice is left to the buyer. Upper

and lower wing panels are interchangeable along with the ailerons. Rigging is simple,

no internal and a minimum of external wiring.

Both the air speed indicator and engine tachometer are mounted on a separate

panel forward of the cockpit in the pilot's "flying line of vision". During dusting

or spraying operations pilots have little time to look inside the cockpit.

Specifications for the airplane are over-all length of 24' 8"; 35' 8" span; gross

weight 3600 lbs; empty weight 2180 lbs; 29 cu. ft. (217 gals.) hopper Volume. Hopper

load is 1000 lbs. The Ag-Cat has been designed to make a continuous 1.5-G turn at

dusting speed and at maximum gross weight.

Our model is designed around a 1" scale bringing the upper panel to a 36"full

span. The .29 power plant is housed behind a dummy 7 cylinder radial engine; with

a short nose moment all movements of control are most responsive. The model floats

in on a monostrut landing gear and a spring leaf swivel tail wheel.

Construction could begin with almost any part of the model. However, we prefer

to start with the fuselage since all members fasten to it one way or another. The

sides are 1/2" sheet balsa broken and shaped as indicated. All formers aft of the

firewall are 1/4" sheet balsa. The firewall is 3/16" plywood. A 1/4" thick disk

of sheet balsa forms the nose of your Ag-Cat. The engine is mounted prone; be certain

the 3/8" x 5/8" hardwood motor bearers are secured to the fuselage accordingly.

Fasten the 3" bellcrank to the plywood platform as indicated. Secure a 1/16"

dia. wire pushrod to the crank with the tail end extending beyond the fuselage.

The deck and nose sections are built up from 1/4" sheet balsa laminations, shaped

as in the cross sections. Prior to fastening the lower 1/8" sheet covering, fashion

the landing gear from 3/32" dia. wire as shown. Sandwich this between two sheets

of 3/32" plywood, fasten to the fuselage. At this point, place the Acme fuel tank

in position in former "B", secure with cement.

As all this is left to dry proceed with the sheet balsa tail surfaces. Both the

vertical and horizontal members are fashioned from 1/4" medium grade sheet balsa.

A large Veco horn fastens the elevator halves and these are joined to the stab with

cloth hinges. These surfaces carry a full radius on all their edges. Fasten the

stab assembly to the fuselage and the fin on top in a previously cut slot. Join

the pushrod to the Veco horn. Be certain these additions to the fuselage are cemented

well.

At his point, the lower 1/8" sheet covering is put in place. A hardwood wedge

is inserted at the tail end of the fuselage, this member carries the tail wheel

assembly. Make the necessary cutouts for cockpit, lower wing and proper fitting

of the engine. Before setting the fuselage aside, shape from 1/32" sheet brass the

dummy landing gear legs, soft-solder to the gear wire.

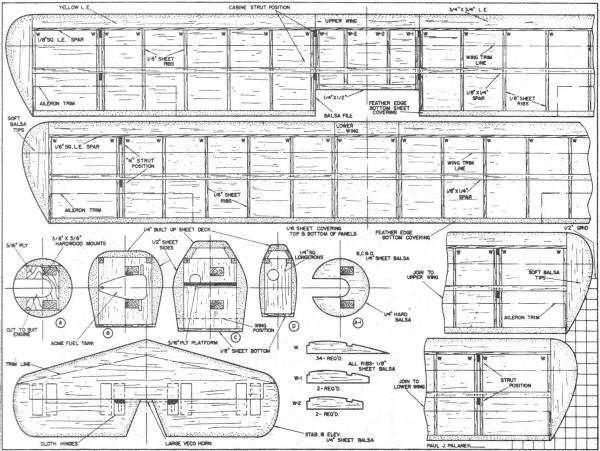

The wing panels are extremely simple, a minimum of structure is employed. All

ribs are 1/8" sheet balsa, the leading edge is 3/4" sq. strip; there is no trailing

edge. Start by laying out the lower sheet covering of each panel. Shape the leading

edge with the proper dihedral at each tip, cement to the lower sheet covering. When

dry, add the ribs; follow with the 1/8" sq. leading edge spars and 1/8" x 1/4" main

spars. Allow this assembly to properly dry.

With the panel sufficiently dry to work, sandpaper the ribs blending in all rough

spots also, feather edge the trailing edge to receive the upper covering. The pur-pose

of the spars is to support the upper wing covering which is 2" and 3" wide sheet

balsa with the joining seams falling on the spars. The wing tips are fashioned from

balsa block, 1" x 1-1/2", cement these in place, when dry shape to proper contour.

Having completed all structures and having brought them to proper finish and

contour, apply two coats of clear dope with a light sanding after each ap-plication.

Cover all wood surfaces with a light grade Silk-span, doping all over as you proceed.

When completed, apply a second coat of clear dope allowing to dry hard at least

ten hours. When satisfied, apply four coats of balsa sanding sealer, sanding after

each brushing. All surfaces receive three coats of Aircraft gray and two coats of

Orange yellow trim. Be certain the lower wing is fastened in place with lower sheet

covering added, then proceed. Allowing time for the above to dry, then add the plywood

cabane and "N" struts. Both are cut from three-ply plywood, take note of the grain

direction, this is important for maximum strength. Assemble the struts between the

double ribs, forcing the cabane struts into the fuselage deck. Both wings are set

at zero degree incidence. This assembly must be done with care and proper fitting.

All rigging is stretch thread, gray in color. The wind screen is .020 celluloid,

the pilot is a painted plastic dummy cemented in cockpit. The line guide is formed

from .020 music wire, cloth bind to the left wing "N" strut. Add antenna assembly,

decal numerals, cockpit liner, instrument fairing and other details now.

The drawing shows the components used in the assembly of the tail wheel. Brass

spring leaf is used for the strut with standard sheet brass for the yoke. The yoke

swivels in the strut with the spring neutralizing the action. This entire assembly

is fastened to the fuselage with two # 3 wood screws.

Our completed Ag-Cat carried a Fox 35 power plant; however, a "29" should show

excellent results - the difference in weight being of little consequence. A prop

of 9-6 proportions will provide good performance. On the field we use 75' lines

with little fear of slack. The Cat has tremendous area and, while under complete

control, in theory we almost have a free flight on our hands.

You will note

photos and plans show a hopper carried under the lower wing along with a 7 cylinder

radial engine in the nose. To add to the realism of the completed model these items

should be constructed and added. The hopper fashioned from 1/16" sheet balsa is

made a permanent fixture of the aircraft. The dummy engine is for display only.

In building, the crankcase is hollowed to fit the shaft and washer of the mounted

engine. The scale prop is fastened to the engine with a modeler's pin. For the radial,

balsa is used throughout. Thread is wrapped around the cylinders to simulate fins.

Crankcase and rocker boxes are painted grey, pushrod and cylinders are black. Remember,

the dummy engine is removed for flights.

Full size working drawings for the Grumman Ag·Cat are part of Group Plan

#461 from Hobby Helpers, 1543 Stillwell Avenue, New York 61, N. Y. (S5c). At right

young Ronnie Palanek, 12, prepares his Dad's model for flight. Dummy engine has

been removed and flying prop substituted for scale exhibition airscrew.

Grumman Ag-Cat Plans Sheet 1

<click

for larger version>

Grumman Ag-Cat Plans Sheet 2

<click

for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted 8/4/2012

|