|

In

2013, flying a radio-controlled airplane model with a 22" wingspan

is no major accomplishment. In 1963 it was a phenomenon. Today's

micro-size servos and receivers and powerful brushless motors and

Li-Ion batteries. Yesterday's models used relays, electronic components

with wires sticking out of them, interconnecting wires, metal frames,

heavy alkaline batteries, and in the case of single-channel models

like the Lil' Roughneck, a rubber band to power the escapement.

Oh, and you had to build the model yourself. It was all very crude

by today's standards. Pioneers like author Aubrey Kochman helped

pave the way for what we enjoy now with ready-to-fly convenience

and at a much cheaper price in inflated dollars (or rupees).

Lil' Roughneck

By Aubrey Kochman

Lil' Roughneck -- A "ballpark-size" radio control low-winger

with a lot of forgiving features, this diminutive darling

will surprise you with its steady flight and sturdy construction

which resists rough landings.

Designer-author-draftsman Aubrey Kochman with his latest

R/C success; being a New Yorker "Koch" is accustomed to

flying in small areas, hence crash-insurance construction.

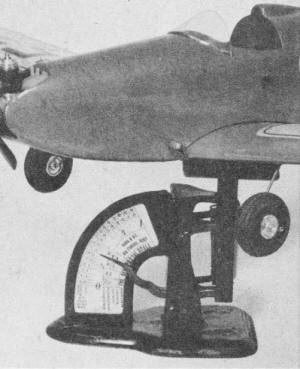

Completed model ready to fly weighs just a wee bit over

6 ounces as shown.

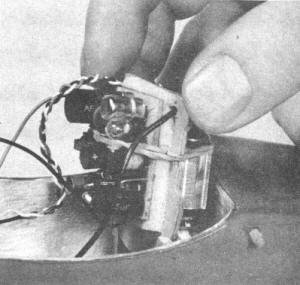

Receiver is cushioned to tray as above. Full size drawings

are on Hobby Helpers' Group Plan #1263. |

Once .01 powered R/C models proved to be an ideal fun ship, their

popularity spread like crabgrass. As is the case with any comparatively

new class the best all-around size and configuration isn't quickly

settled upon. We have witnessed flights of these mini-ships

with as little as 12" and as much as 36" spans. In our opinion the

12" jobs were too hot to handle while the 36" models were definitely

underpowered. Unless you are interested in flying either the largest

or the smallest .01 R/C in the world we see little attraction in

either extreme. From past experience, we have learned that

.01 models have extremely poor ground handling characteristics.

R.O.G. (rise-off-ground) take-offs are usually a matter of luck.

Unless very smooth runways are provided, landings - right side up,

that is - are also uncertain. Ground loops or cart wheeling can

be the rule rather than the exception. Even a perfect approach and

touchdown can't guarantee a smooth landing. A wire skid would probably

be the best answer, but our aesthetic values ruled against it. As

you can guess we feel a trike gear is of little value in so small

a model. Therefore we use a two-wheel wide-track gear. And the extra

weight of a nose gear can be put to better use by beefing up the

fuselage front with additional lumber. Silk covering was

ruled out as too heavy while tissue has always seemed to us to have

an affinity for tough weeds that can make Swiss cheese out of most

and any airframe. Although weed-proof, the single-surface sheet

balsa wing at best is pretty flimsy so it, too, was ruled out. Not

much left to choose from, so we settled on a double-surface sheet

balsa wing (which is our favorite anyway). So look out weeds-here

we come! In our design approach to Lil' Roughneck we have

attempted to lessen the jump these small models make when entering

and recovering from a turn. To accomplish this we lengthened the

tail moment to gain longitudinal stability and reduced wing dihedral

to an angle which proved a good compromise as far as lateral stability

goes. Construction-wise, this model is rugged enough to take it

when we miss the weed patch and has been found to be practically

warp-proof. Once flight trimmed, Lil' Roughneck will prove a consistent

flyer which is as it should be for a model designed primarily for

fun flying. Our completed model, painted and ready to fly,

weighed in at just over 6 ounces. To match this weight it is very

important that you spend a little extra time at the balsa rack and

choose your stock wisely. The wing, which is built in halves

and joined together glider fashion, is more easily formed if 6"

wide stock is used. Choose straight grained medium soft balsa sheets.

We used Sig contest balsa. Cut bottom sheets to outline shape. Cut

all ribs from 3/32" soft sheet and cement them in place. Add 1/8"

dowel leading edge. This dowel greatly strengthens the wing and

guards against leading edge knicks and cracks. Its weight is practically

negligible so don't leave it out. Taper trailing edge of the bottom

sheet to conform with rib airfoil. Add landing gear legs. Cut top

sheet oversize to allow for the bend and cement it to the dowel,

ribs and trailing edge. This is the most critical stage of construction

as any built-in warps cannot be corrected once the cement has thoroughly

dried. Rough carve tips from 1/2" x 1/2" soft balsa and cement in

place. Sand to final shape when both wing panels have been completed.

Join the panels, carefully checking for proper dihedral angle. When

this joint is thoroughly dry and with the wing still blocked up,

add 1/16" sheet center section doubler. Stabilizers of 1/16"

sheet have always given us trouble since they seem to warp so easily

and upset trim adjustments. To overcome this, we resorted to a double-surfaced

stab which like the wing is practically warp-proof. Choose very

light 1/32" sheet, preferably with some quarter grain mottling.

Cut both top and bottom sheets exactly alike except for the fin

notches which are in only the top sheet. The single 1/16

x 3/32" deep medium hard spar may be cut or sanded so that it tapers

symmetrically from the center to a feather edge at its tips. Cement

spar to either of the stab sheets. Run a bead of cement all around

this sheet and, along top edge of spar. Position second sheet accurately

and hold them together with clamp clothes pins or masking tape (pin

holes would mar the final appearance). Again check carefully for

warps and remove them before the cement has thoroughly dried.

The fuselage should offer no problems. Side doublers, longerons

and vertical braces are cemented in place before you add the sides.

Nose tripler is added after formers A, Band D are installed. We

recommend a white glue when installing former A. Note that the top

longeron extends 1/32" above side sheet to give 1/32" top sheet

good gluing surface. Install escapement and torque rod before

adding top sheeting. The only tricky operation for some

could be fitting the curved top sheets. Bond paper fitted and then

used as a pattern for the balsa saves both time and wood. After

cutting front 1/16" sheet and the rear 1/32" sheet according to

the paper pattern proceed as follows. Rub a thin coat of cement

onto the underneath side of the balsa and moisten the outside with

warm water. As the cement dries, the sheet will begin to curl. With

a little added assistance, the sheet assumes the proper curvature

and very few pins will be needed to hold it in place. Do not cut

out the cockpit until after the front sheet has been cemented in

place. The bottom 1/32" sheet, rearward of the wing, is

applied so its joints meet on the 1/16" sq. cross braces.

Cut

the fin from medium 1/16" sheet. the rudder from soft 1/16" sheet.

The two fin tabs which fit through the stabilizer slots insure a

strong joint and perfect alignment - provided, of course, that the

slots have been cut accurately. Finish is a matter of choice

and will depend upon the undoped weight of the finished model and

how balances with all components installed including receiver, batteries,

escapement rubber. We used three coats of clear dope over

the entire model, sanding well between each coat and lightly sanding

after the last coat. Colored dope was kept to a minimum aft of the

CG so as not to upset the correct balance we had achieved through

careful construction. Pin striping was done with 1/32" Chart-Pak

tape, available at most art supply stores. Clear dope applied over

the tape will keep it from peeling. Glide test the model

before attempting powered flights to familiarize yourself with its

flying speed. Slight alterations in trim is provided by the stabilizer

trim tab. Make your first powered flight with engine at moderate

speed or with the prop on backward in case thrust adjustments require

some change. When trimmed properly for a shallow climb and a slight

turning tendency, (to whichever side the model trims easiest) Lil'

Roughneck, through its warp-proof construction, will remain a consistent

performer, requiring only slight stabilizer trim tab adjustments

to compensate for various wind conditions. Bill of Materials:

Two sheets 1/16 x 6 x 36" medium soft straight grain; 1 sheet 3/32

x 3 x 36" soft; 1 sheet 1/32 x 3 x 36" soft quarter grain; 1 sheet

1/ 16 x 3 x 36" medium; 1 sheet 1/32 x 3 x 36" soft straight grain;

1 pc. 1/2 x 1/2 x 36" very soft; 3 pcs. 1/8 dia. x 12" birch dowels;

1 pc. 1/16 x 1/16 x 36" med. hard; 1 pc. 1/16 x 3/32 x 36" med.

hard; 1 pc .045 music wire; 1 pc. 1/16" music wire; 1 pc. 1/32"

music wire; 1 pr. 1-1/4" wheels; 1/8" plywood; 1/16" plywood; 1/32"

plywood; 1 pkg. 2-56 blind nuts and bolts; 1 Acme #913 battery holder.

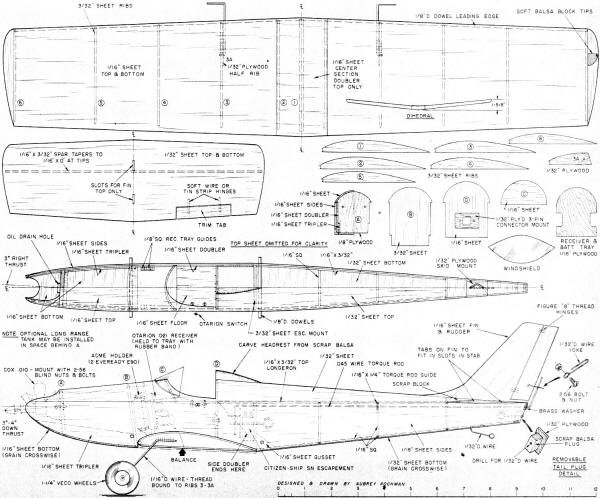

Lil' Roughneck Plans

<click for larger

version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted June 15, 2013

|