prop combination - make this a truly great stunt design." Great care

in planning was used to obtain a model that was lightweight and would fly

relatively slowly on 70-foot, 0.015" diameter (low drag) steel lines. Its 56" wingspan

and Super-Tigre .35 BB engine with a 50-oz. flying weight on 70' lines reportedly

results in a near-perfect stunter.A Precision Aerobatic Airplane - The PA-6

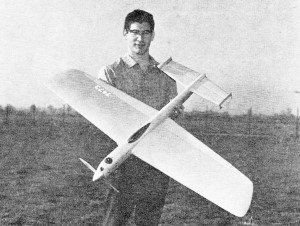

Sleek is the word! Displayed by its designer, PA-6 shows compactly

cowled nose, flowed-in canopy, and smooth surface of sheeted wing.

Cleverly blended design factors - notably engine/prop combination - make this

a truly great stunt design.

Bob Baron

My first thought in designing this plane was to use the maximum allowable line length

of 70 ft. and to take advantage of the lower drag of .015 lines for engines of 40

and below displacement. Together with a flying speed below 60 mph, the apparent

(angular) speed would be quite slow. The important trim parameters - leadout sweep,

center of gravity, tip weight, and handle width - were to be made easily adjustable

on the field to facilitate trimming.

Rounding an outside loop. Ship has moderate, but very steady

pull through all its maneuvers and nearly constant airspeed.

Several features were incorporated to reduce the physical effort of flying to

the minimum. The wing was to be very rigid and to hold its airfoil, which led to

an all sheet wing. Ease of maintenance and everyday handling were considered desirable

assets. Most important, the prop (10-4) would be of relatively low pitch so as not

to stall under loads, and the corresponding high rpm would use most of the available

horsepower of our present engines.

The resulting 50-oz. ship flies at 54 mph on 70-ft. lines and can be flown through

every corner with no tendency to yaw or roll. The pull is moderate but very steady

throughout the maneuvers. The flying speed is very nearly constant due to the low-pitch

prop not stalling, as does the traditional 10-6. In the wind the low pitch tends

to brake the plane. This minimizes the vicious whipping tendency that gives stunt

flyers the jitters. A balanced elevator, together with a proper CG, handle, and

control setup, reduces the physical effort at the handle, over a conventional arrangement.

The sheet wing (13.5 oz.) weighs less than the equivalent cap-stripped D-tube.

A table of weights is provided so the builder can guide himself toward a finished

weight of no more than 50 oz. Extruded nylon bearings were used in the hinges to

eliminate a frequent trouble spot. A fiberglass cowling and strong front end minimize

the usual deterioration of the nose. This plane has a useful life of around 2,000

flights, after which most flyers would be quite tired of it anyway.

The tank is readily removable, since when permanently installed, it will no doubt

leak due to "Murphy's Law." Aluminum plates in the bearers keep them from crushing

with age. The finish was dope, filled and colored, followed by epoxy paint. The

epoxy paint has amazing resistance to fuel, and frequently the author takes ten

straight flights without bothering to clean the ship. A stooge takes care of the

dirty work, as no one would launch a plane that filthy.

Provision of extra leadout bushings permits fine adjustments.

Play line rake and tip weight until ship does not yaw on sharp corners.

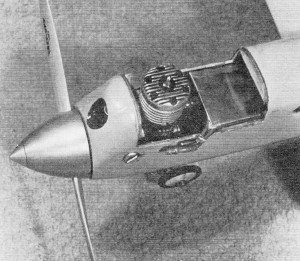

Engine-tank compartment given two coats fiberglass resin. Tank

removable. Super Tigre 35 combat engine permits 15,000 on 10-4.

The choice of wood is vital if the weight is to be kept below 50 oz. Wood of

five- to seven-pound density will give the weights listed on the table. Wood ordered

directly from Sig with a request for medium-soft will be adequate. The solid flap

and empennage are actually lighter than a built up surface, since the finish weighs

more over an open surface than a closed one. Glue is the real culprit in the weight

department. For curiosity, weigh all the ribs in a stunt wing, then hollow them

and check again. It's hardly worth the effort.

Building can be greatly speeded by assembling all components (wing, tail, fuselage)

as completely as possible separately. The fuselage in particular is built quickly

by tack-gluing the blocks and sanding everything to shape without the wing, tail,

and tank vents being in the way. After this is done, the blocks and underwing cut-outs

are removed and the wing, tail, and gear can be installed leaving relatively little

construction to be done.

The wing planking is spliced chord-wise as shown for a specific reason. The three

pieces as shown make it possible to glue the planking with little danger of it popping

up after the job is completed. First glue the trailing edge sheet and leading edge

stringer with the spar in place, but not glued. Before the glue sets thoroughly,

steam the wing as straight as possible. When you are satisfied with the alignment,

glue the main spar. Install controls and continue with the center piece. After each

sheet is in place smear each rib with glue where it meets the planking to prevent

the sheet from separating from the ribs. Do not substitute 1/16 sheet for the 3/32

planking, as it makes the job too critical. Do all sanding with a block to prevent

sagging between the ribs. Sand only enough to smooth the seams. The inboard tip

sanded and hollowed should weigh .75 ounce and outboard one should weight 1.00 ounce.

The fixed tip weight is .50 ounce giving .75 ounce of tip weight to start. The additional

.25 to .50 ounce needed is put in the tube as determined by test flights.

Table of Weights

13.5 Wing unfinished ready to install complete with

all controls and tip weight

3.0* Tail assembly including controls and rudders

2.0 Tank

0.75 Three 1 7/8" diameter Williams Bros. Scale wheels

2.0 Veco 2" spinner

8.5 Super-Tiqre .35 BB

0.5 Prop

8.0 Fuselage completely sanded with blocks

left solid with all formers and mounts installed

2.0 Assembly of components and installation

of controls, fillets

0.5 Fiber-glass cowling

8.0 Finish from bare wood

Total -- 48.75

oz.

Finish:

0.5 Two thinned clear on bare wood

2.5 Paper covering + three thinned clear

3.0 One coat of given mixture

2.0 Two coats of Hobbypoxy color

Total -- 8.0 oz.

*1/2 oz. too heavy here means 1 1/2, ounces of nose weight!

It is imperative that epoxy glue be used for the engine bearer-doubler, nose

gear mount-bearer, wing-fuselage, and main gear-fuselage joints, as well as all

horn and hinge mount installations, if the airplane is to last for a reasonable

time. The entire engine-tank compartment must be given two coats of fiber-glass

resin directly over the bare wood.

The finish was two thinned coats of clear on the bare wood, covered with Silkspan,

three thinned coats of clear. Then spray on one coat of a mixture of equal Volumes

of clear, thinner, talcum powder, and color. This last step should add no more than

three ounces when sanded properly, yet will fill all the grain. Finish the ritual

with two coats of Hobbypoxy color applied with an airbrush, not a gun.

A few words are in order on the engine. The usual plain-bearing stunt engine

has neither the power nor strength to run repeatedly at the 15,000 rpms required

by the 10-4 prop. The Super Tigre 35 BB combat mill, model G21/35, with restrictor

installed, shows no tendency to overheat at the high rpms and low airspeed of this

design. In addition, it is operating comfortably below its maximum output on a very

mild fuel of 75% methanol and 25% castor oil. No shaft extension is used, as this

is only a source of additional vibration.

Props must be carefully balanced to prevent excessive wear on both engine and

plane. The Tigre starts very quickly when hot, whereas many stunt engines simply

will not start until they have cooled. This characteristic makes it possible to

fly seven patterns an hour when practicing hard for a meet. This engine is particularly

nasty when new, but after a gallon of fuel is run through in five-minute periods

on a 10-4 it becomes relatively docile.

Proper trimming is essential to the success of any stunter. Our CG is very near

the aerodynamic center of the wing which means that inertial and not aerodynamic

forces are those principally overcome to initiate a maneuver. My handle is 2.5 inches

in line width with the control system shown and the lines are .015 x 70 ft. as measured

from center-of-plane to center-of-handle. It is very strongly suggested that the

CG and control system be used exactly as shown and that individual preferences in

feel be adjusted with handle line width only.

First determine if the engine runs exactly the same speed in both directions.

If the outsides are faster than the insides, or inverted flight is faster than right

side up, the tank is high and the engine must be raised with washers. Next establish

the engine setting that gives 55 mph on a Rev-Up 10-4 prop.

Steam the wing until line tension is exactly the same right side up as inverted.

Do not adjust this tension by bending the flaps. If the ship loses tension on insides

but not outsides, then there is more tension inverted and the wing should be steamed

accordingly. If tension is lost equally in both directions on loops, try additional

tip weight and if that doesn't help, put in additional line sweep. Play with tip

weight and line rake until the ship does not yaw on a sharp comer. The actual rake

angle agrees very closely with the theoretical calculations of William Netzeband

as published in the Sept./Oct. 1966 issue of American Aircraft Modeler.

I think you will find this ship equal to the competition, and also a pleasure

for everyday flying.

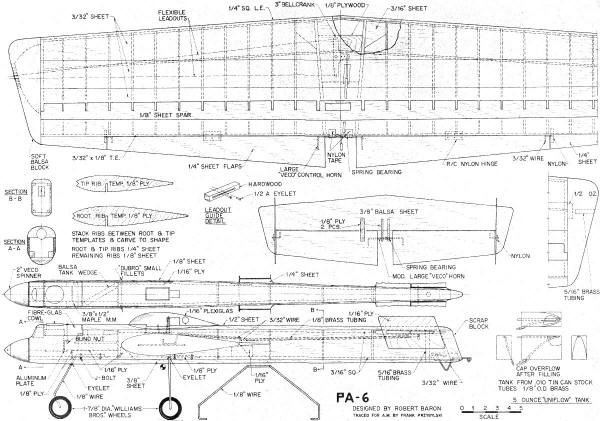

PA-6 Plans

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted February 16, 2022

(updated from original post on 8/19/2012)