|

Airplanes

and Rockets visitor Rob K. requested that the article be posted

for the Small-Fry Special, a 1/2A-powered beginner's control-line

model. Its all sheet balsa construction with the engine mounted

using rubber bands makes the Small-Fry Special easy to build and

repair, and provides a extra helping of forgiveness if you happen

to botch a landing. The wing even has ailerons glued permanently

in position for a right roll to help keep the lines tight. Photos

and flying instructions are included in the article from the May

1969 edition of American Aircraft Modeler. Small-Fry Special

For about $3, less its 049 engine, you can quickly build

and fly this sturdy control-line trainer. Howard

C. Mottin

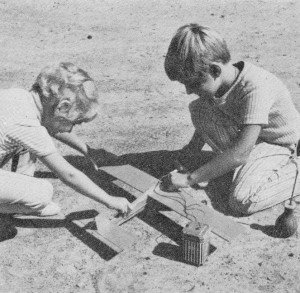

With this reliable trainer the kids can go flying by themselves.

Today's easy-starting 049 engines are no problem for a youngster.

Flyer's sister holds.

Balsa models are painted with model airplane dope so that the

fuel and exhaust do not seep into the wood. Use two coats of

clear and two coats of color.

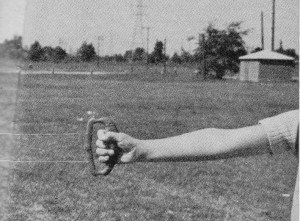

How you hold control handle is important. Keep your arm straight

at all times. Lift arm for up, lower for down. Level is neutral.

Line on top is for up, line on bottom for down. Raising your

arm causes pull on up-elevator line and releases the other line

slightly, causing the model to climb.

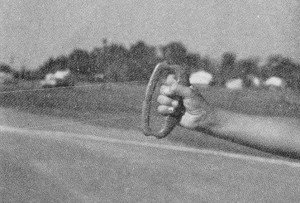

Down-elevator is the opposite of up movement. Positions are

a bit exaggerated here. Arm motions only prevent over-controlling.

Take off downwind so that model is airborne with wind keeping

line tight.

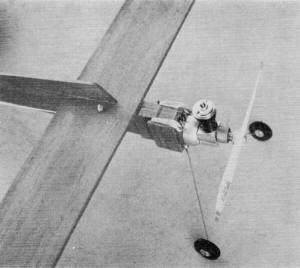

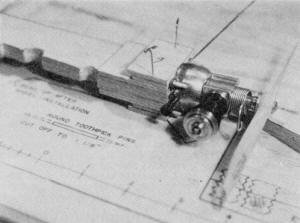

Engine is held in place with rubber bands looped around

the mount and toothpick sections which key the motor on the

nose. It will come off harmlessly in a bad crash, but is secure

in flight.

Put the engine on the toothpick studs to keep them properly

aligned while assembling the nose doublers. Be careful to keep

glue out of the intake screen on the rear of the engine.

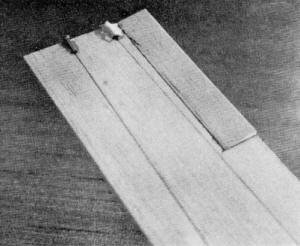

Using model cement, glue short lengths of 1/2"-wide pinking

tape to the top side of elevator and stabilizer with plenty

of overhang. When dry, fold down and across to opposite half,

then glue again.

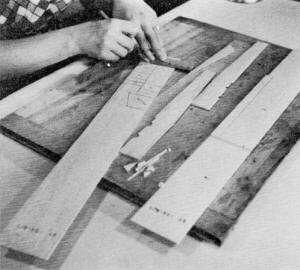

Construction begins with cutting the parts out as per the

plans. Only two sheets of balsa are needed, model airplane glue,

sharp knife, ballpoint pen, and soft building board.

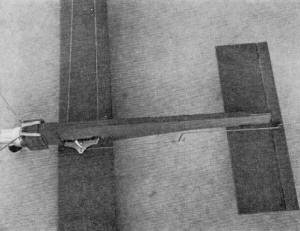

Leadouts from the bellcrank leave the inboard wing tip through

eyelets or short lengths of tubing. These must be securely glued

and gauzed to the wing. Note the aileron position.

Wire pushrod between bellcrank and control horn on elevator

has a double bend at its middle so that it can be adjusted for

neutral elevator position with bellcrank parallel to fuselage.

So you want to fly control-line models? Then try a rugged Small

Fry for an easy, economical way to start. The parts for the basic

model, namely the two pieces of 1/8-in. balsa, can be bought for

under a dollar. The rest of the hardware items can be purchased

for around $1.00, making the price for the works (less engine) around

$3.00, including paint. A 1/2A or 049-size model can

be difficult to fly because of its small size, and because it flies

on shorter lines. Contrary to popular belief, larger models, say

a 35-size, are a lot easier to fly, but they are also a lot more

expensive. Thus, thousands of inexpensive 049 engines are sold every

year, only to be stored in a drawer when the first building project

ends up in a pile of balsa, or worse yet, is never completed because

of the building time involved. The first thing to

learn in the model plane hobby is to take enough time to perform

each step properly. Something left undone or hurried over will end

only in disaster. If you follow the construction steps in this article

you will end up with an airplane that does fly well. This model was test-flown by my 5-year-old daughter! It did take

a few crashes before she flew successfully. We went through five

versions before we came to the final one, which is a cinch to fly.

If set up as described, it will fly for anyone. Another favorable

point is that it is rugged enough to survive a few mishaps, and

easy to repair or rebuild. Simple parts make it easy to repair.

But in case of a total break-up it's not hard to build a new one

reusing the same hardware. The important thing is not to become

discouraged if your first few attempts at flying result in failure.

Remember that even those of us who have been flying for years crash

occasionally. You will crash occasionally when you

are starting out. Remember what you did wrong and correct the mistake

on your next flight. Not to scare anyone away, these are just facts.

It is possible to fly successfully right from the start. All that

is required is to remember two controls, Up and Down. In between

these is Neutral - where the plane should be flown. It's that simple.

Just give a little up to take off and, once airborne, come back

to neutral and fly the whole flight. Now let's get

started. First requirement is the Cox 049 engine. I bought a Cox

Baby Bee for my model. I also used an old engine from a long-gone

plastic model. If you already have an engine you're all set. If

not, I would recommend purchasing a Cox Baby Bee or Quiet Zone engine.

These are available almost everywhere from hardware stores to department

stores and at all hobby shops. While you're at the local hobby supplier

buy the rest of the materials on the list and you are ready to start

building. A brief note on the balsa wood: try to get

a piece that is not badly warped. Hold the board on its side and

sight down the long edge. In this way you can see all the bends.

Pick a board that is fairly flat or that has a gradual curve, not

one that looks like a roller coaster. Besides the

building supplies on the list there are a few other items you will

need. If this is your first building project, you will need a knife

(X-acto No. 8 will be adequate), glue (Testers B, Ambroid, etc.),

a pack of model "T" pins, and a straight-edge (this can be the metal

edge of a common dime-store wooden ruler). Other items are pliers,

wire cutter, building board and sandpaper. An optional item that

is nice to have but not mandatory is a carpenter's combination metal

square. It can be purchased for under $1.00 at just about any hardware

department. It also can be used as a straight edge.

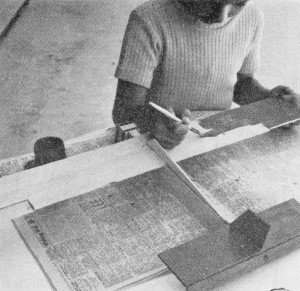

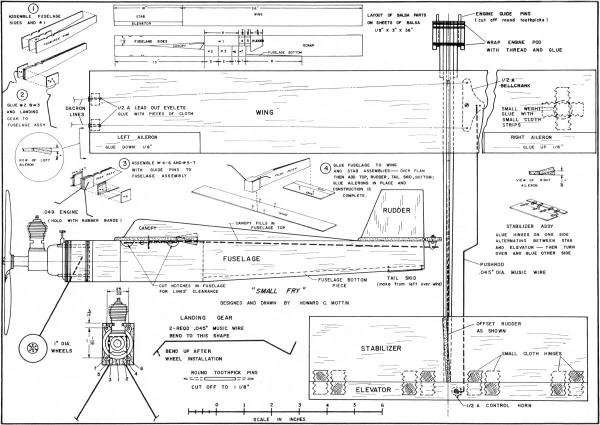

Construction: Layout all the parts on the two 1/8"

balsa sheets. A ball-point pen is used to draw these, but do not

press too hard. The sketches show how to layout these parts. It

will help to number the nose-pod pieces to avoid confusion. The

dimensions for the various pieces can be obtained from the side

and top views on the plan. When drawing the lines across the sheets,

use the square to keep these perpendicular to the sides. When the

layout is completed, cut out all the balsa parts using a sharp hobby

knife. A large balsa piece will be left over. Save this for repairs

or your next plane. We are now ready to begin assembly. I usually build the fuselage first and, while this is drying, work

on the tail or wing assemblies. Lay down a small piece of wax paper

(approx. 12" square) on your building board. This will prevent the

parts that will be glued together from sticking to the board. The

first step is to glue the two fuselage sides and the front center

(No. 1) piece together. Spread a liberal amount of glue on both

sides of the center piece and put a small bead of cement on the

tail end of one fuselage side. Then put the three pieces together

and pin down to the board on the wax paper. Put four pins through

the front section to the board, checking the alignment of all three

pieces at each step. Pry up the tail end of the fuselage side next

to the board and put a toothpick under it, so it is approximately

1/16" off the board. Pin the tail ends together with two pins.

While this is drying you can start assembling the two outside

pod pieces. Take four round toothpicks and cut off to the length

shown on the plans. Now lay pieces No.4 and 5 on the building board

with the dotted lines up. The dotted lines -should be 3/16" from

the top and 1 1/16" apart. Using just the point of the knife at

an angle of approximately 45 degrees with the piece, cut triangular

grooves in these pieces centered on the dotted lines. Do this carefully,

taking several small cuts. Measure the groove between these cuts,

using the cut-off toothpick as a gauge. Stop when the toothpick

just fits in the groove and the top edge is flush. Put the toothpicks

in the slots and place the No.6 or 7 piece on top and check the

protruding part of the toothpicks for alignment, using the engine

mounting holes for a gauge. MATERIALS LIST

Two sheets 1/8 x 3 x 36" balsa One piece .045 dia. x 36"

music wire 1/2A Bellcrank, Perfect #233 1/2A Control horn;

Perfect # 234 1/2A lead out eyelets, Perfect #236 Small

cloth hinges, Perfect # 202 Wheels 1" dia., Perfect #62

Miscellaneous: Round toothpicks, thread, small rubber bands (size

16), dope (fuel-proof), thinner, brush (1/2 or 1/4"), Goldberg 1/2A

handle with Dacron lines. If everything checks out,

glue these two assemblies together. If everything was not right,

make a new piece from the scrap-balsa piece. Use a liberal amount

of glue in the grooves to glue in the toothpicks and pin these two

assemblies down to the board to dry. Check the alignment of the

front edges to make sure they are flush and double-check the toothpicks

with the engine. Now take out the two pins in the front

end of the fuselage assembly and glue the No.2 piece flush with

the front. Unpin the entire fuselage assembly after the glue has

dried. Place the No. 3 piece and the 7-5 assembly and 4-6 assembly

on the fuselage and hold the front end with one hand. Use the engine

mounting holes as a gauge once again and check the mounting alignment.

Chances are that the pins will be too wide apart. But if the engine

slides on, go ahead and finish the pod assembly. If the engine didn't

fit, slide out the No.3 piece. Lay a piece of sandpaper flat on

the building board and lay the No.3 piece on it. Holding it flat

against the sandpaper, slowly slide it back and forth sanding it

down on one side. Recheck the fit after every three or four sanding

strokes until it fits snugly between the fuselage assembly and the

7-5 piece. When everything fits properly remove the engine, and

glue the No.3 piece to the fuselage assembly. While

this is setting, mark the location for the landing gear mounting

hole. This is approximately 5/8" from the front and 5/8" from the

top. One of the leftover round toothpicks can be used to start these

holes. The two landing gear wires should be made to the shape shown

on the plans. Now mount the wires to the fuselage assembly and cut

grooves so that the top of the wire is flush with the surface. The

engine pod is completed by gluing on the two outside pieces, reinforced

by wrapping with thread at the front and back. As the assembly is

pinned together, check the alignment, using the engine as a gauge.

Spread a small coat of glue over the thread and over the entire

front surface of the pod. The triangular hole in the bottom of the

fuselage can be filled in with a piece of scrap. Next

comes the assembly of the stabilizer or "stab." If you have not

already done so, cut apart the elevator and stab. With a piece of

sandpaper, round off the leading edge of the stab and the two edges

that will form the hinge line. It is easier to work with the stab

if it is pinned down to the building board. The stab and elevator

should be lined up properly and an approximate one-inch gap left

between them. Now take four of the small cloth hinges

and cut them in half. With a ball-point pen, make a small "x" at

each position where the hinge will be glued on as shown on the plans.

Then taking them one at a time, put a small glob of glue on the

"x" and press on the hinge cloth leaving about 2/3 to hang over

the edge. After these have dried, unpin and turn over the stab and

elevator and again mark an "x" where the hinge will be glued on.

This will be opposite to where the hinge material is sticking out

of the pieces. Slide the two pieces together so that all the hinges

are sticking straight up and pin to the board. Then repeat the gluing

procedure making sure hinges are tight. Now lay the

plan on the building board and lay a piece of wax paper over the

top view. The stab is pinned down to the location on the plan, and

likewise the wing. Glue on the fuselage following the location on

the plan. While this is drying you can glue on the leadout eyelets

and the wing tip weight. But remember the plane is upside down,

so glue them on the opposite ends of the wing from what you are

looking down at on the plan. The weight can be just about anything

from a flattened-out fishing sinker to a washer (about the size

of a penny). Small pieces of left-over hinge cloth should be glued

over these to strengthen them. We're now in the final

stages of construction. The canopy piece (top) and the rudder are

now glued on. Be sure and offset the rudder so the plane will have

a tendency to turn (yaw) to the outside of the circle. Cut out the

ailerons and glue in place as shown. The left aileron will be down

and the right will be up. The holes for the bellcrank and control

horn are added. They can be made using a round toothpick as a drill.

The control horn can be fastened on and a small amount of glue should

be put over the nut to keep it from working loose. Do not turn the

nut so that the balsa is squeezed together, but merely bring it

up snug to the surface. The glue will keep it tight. The bellcrank will be installed after the plane is painted. The

wheels now are added and the protruding wire bent up so they will

not slide off. Make a small wire tail skid from left-over wire and

glue in place at the bottom of the tail end of fuselage . This will

prevent the balsa from being scraped away. The one

remaining task is to paint the little gem. Since this plane will

never be a candidate for a best-finish award, there is no sense

in spending a lot of time here. Besides, at this point you probably

can't wait to get it into the air. So give it two coats of clear

dope followed by two coats of your choice of color and call it a

day. Be sure and coat the engine pod area thoroughly to keep the

fuel out of the wood. Now make a pushrod from the

left-over landing gear wire to the shape shown on the plan. Don't

forget the "Z" bend in the middle as this is used to adjust the

length should one of the ends be a little off. When the paint has

dried, attach the pushrod and bellcrank. Line up the bellcrank so

it is parallel to the fuselage and look at the tail and see if it

is in the neutral position (elevator straight with the stab). If

it is not, adjust the length accordingly by bending at the "Z" until

it lines up. Take off the bellcrank and thread the Dacron flying

lines through the leadout eyelets and the holes in the fuselage.

The lines should be tied to the bellcrank using three or four good

knots. Tug on the lines to make sure they are securely tied. Bolt

the bellcrank back on the fuselage and bring the nut snugly against

the wood and add a dab of glue to hold it securely. The construction

now is complete. Flying: If this is your

first attempt, the best advice is to find someone who knows how

to help you. But since this is not always possible, and since human

nature is to "go it alone," I will give the next best advice. First,

if you have purchased a new engine, you must learn how to start

it and how to keep it running. Follow the instructions on the engine

package. You can use the plane itself, or a small test stand consisting

of a board with the engine attached with wood screws for the break-in

period. You should run at least four tank-fulls of

gas through the engine before attempting any flying. By this time

you should have learned how to set the needle valve so that the

engine will run steadily for the complete tank of fuel. If not,

keep on trying until you do learn. We will have enough problems

with flying and can not afford an erratic engine run. After you

have learned how to start the engine, and have broken it in attach

it to the plane with two rubber bands per side. Check the installation

and make sure the engine fits securely and there is no looseness.

There is a little scheme we can use to make sure our

first flights are a success. This is to spring-load the elevator

so that, in effect, the plane will fly itself. This is very easy

to do and I recommend it if this is your first flight. All you need

are two rubber bands and three pins. The thin small rubber bands,

about 1 1/2" to 2" long, are best. Put one pin in the edge of the

elevator opposite the rudder. Loop one end of a rubber band around

the pin in the elevator and the other end around a pin attached

to the rudder. With no tension on the flying lines this rubber band

should hold the elevator in a slight up position (1/16"). Now unhook

the top rubber band and turn the plane upside down. Loop the second

rubber band around the pin in the elevator and around a pin fastened

to the fuselage. This should be positioned to just hold the elevator

in neutral. Now attach the top rubber band and recheck the position

of the elevator. It should be in a slight up position with both

rubber bands attached. If not, add a little more tension to the

top rubber band. With this little scheme the plane will actually

fly itself and you will still be able to control it by over-riding

these spring-loads. If the plane should go slack on the lines, which

happens most of the time in windy weather, the plane will continue

to fly and you will have no problems. For your first

flights you should pick a day when there is little or no wind. Pick

your flying site carefully. The most important thing is to make

sure that there are no overhead power wires in the vicinity. A good

site is one where there is a smooth takeoff area approximately three

quarters of the flying circle over a grass area. This will help

prevent damage to the aircraft. If we have these conditions present

then we're ready to start flying. Put your plane down

on the downwind side of the circle so that it will be crosswind

at takeoff. Then unwind the lines to the center and make sure they

are not tangled. This can cause sticky controls. Next, a pre-flight

check of the controls is in order. Have your helper hold the plane

at flying height and, keeping the lines tight, hold the handle in

neutral position. You should be facing the model with your arm pointed

directly at the model. Your helper should check and see if the elevator

is in neutral (straight with the stab). If it is not, adjust the

length of the lines until it is. Then check both up and down control

and come back to neutral and check again.

You

are now ready for the big moment. Fill the fuel tank half full by

holding the plane on its side and then start her up. Hold the handle

again in neutral position or with a little down control and signal

your helper to release the plane. Let the plane roll along the ground

and fight the tendency to give up control. The plane will rise on

its own if it is neutral and fly at shoulder height. Try to keep

it in level flight about 10 feet off the ground and soon the engine

will quit. As the model glides downward, give up control, and it

will settle to a three-point landing and it's all over.

If this is the way your flight went you are ready for your second

flight as soon as your heart stops pounding. But, if you

had problems with the first flight, here are some additional words.

First, recheck the controls. If the plane flew high when you thought

you were holding neutral, readjust the lines to give a little more

down or readjust the top spring tension to give less up. If the

plane did not take off, but rolled along the ground until it hit

the grass and quit, you can give a little more up, or try another

flight, without changing anything and give a little up control after

it has rolled about 10 feet. But come back to neutral as soon as

it is airborne. Too much up on takeoff can be disastrous and sometimes

results in a wingover straight into the ground. If you got

the plane into the air, but had trouble keeping it level, this is

caused by over-reaction or over-control. This is a common fault

with beginners. This will clear up with more experience, but keep

in mind that only a little arm movement is needed for control. Also,

with this spring-loaded elevator, all you should have to do is just

hang on and let the plane fly itself. What usually happens

is that you are applying control without realizing it. Remember

to point your arm straight at the plane as if it were an extension

of the control lines, and you should have no problems. If you should

happen to crash, check over the plane before attempting another

flight. Make sure everything is proper. Now that you have

earned your wings, welcome to the U-Control flying sport!

Small Fry Special Plans

<click for larger

version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted 11/13/2012

|