|

If you believe that servos with metal gears signify the latest and

greatest in reliable, robust, modern radio control actuation, you

are probably right... unless of course those actuators happen to

be these metal-geared servos from the 1950s. In that case, you might

look at them and wonder how anyone ever managed to get model airplanes

into the air and back safely on the ground when using them. Guys

spent a lot of time and money building large, heavy airframes and

used low power-to-weight ratio engines for lofting vacuum tube receivers,

bulky actuators, and wet-cell batteries into the air. Rubber-band-driven

escapement mechanisms were probably more advanced in design and

implementation than electromechanical servos of the era. Early gimbals

were not gimbals at all, but single-axis control sticks (arms) attached

to rigidly fixed potentiometers. The modern equivalent of a Beep

Box would be the spread spectrum sequencer that encodes the proportional

control input. I don't know if this report was exhaustive based

on all equipment on the market at the time, but the tabulated series

of equipment in the list at the end is pretty brief.

Radio Control Equipment

|

Strat-O-Seal's rotary magnet Strat-O-Rite

actuator shown mounted in fuselage mockup.

E.C.C. Telecommander's escapement.

Ace Radio Control's hi-resistance actuator.

"Rite-Controller"; pulse sequence or

proportional.

Branstner's motor-driven servo available

in two types.

Clockwise from lower left: Citizen-Ship

PSN escapement; Bonner's Standard escapement; Adams rotary

magnet actuator; Berkeley's Super Aerotrol escapement; Bonner's

Compound escapement.

Dmeco (deBolt Model Engineering Co.)

3PN Multi-Servo; one of four versions.

Polk's motorized centrifugal Flyball

actuator.

Rockwood Radio Control's motor-operated

servo.

Stanco split drum belt drive mechanical

pulser.

|

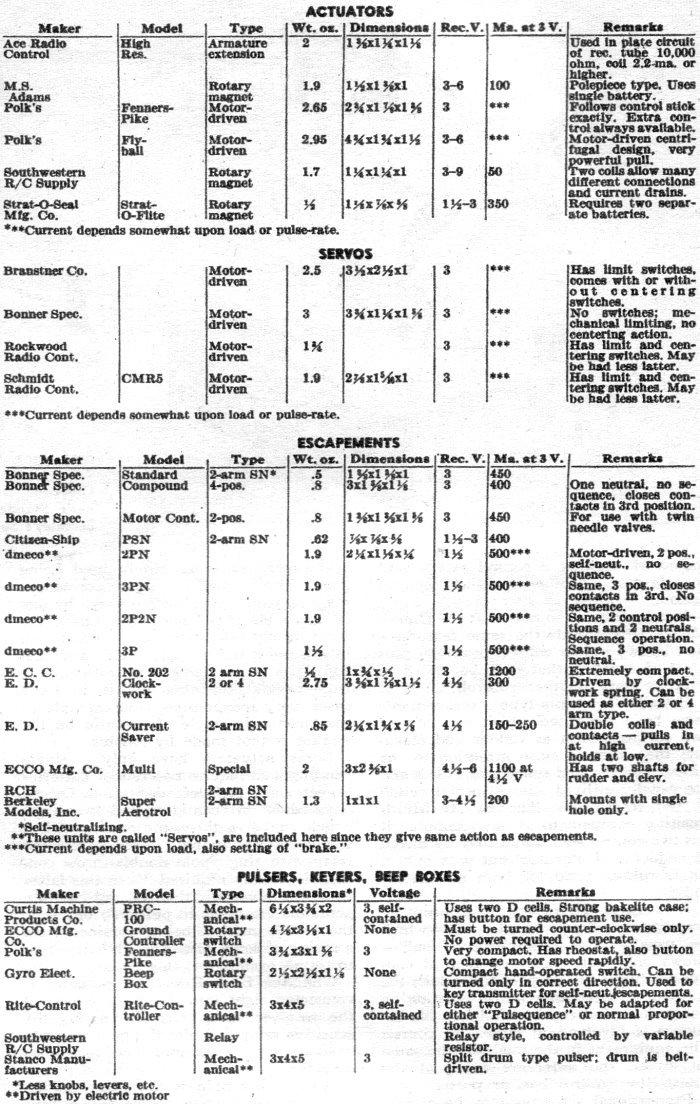

Helpful Data on Surface Movement Devices

Today the escapement is still the most widely used surface mover,

but various forms of proportional control are catching on fast.

Just to get our terminology straight, let's jot down the names of

some of these units, and then discuss them at more length. While

we're at it, we'll include the control boxes used at transmitter

for the various systems.

Escapement - generally considered to be a sequence-operating

device; to get control movement, you have to go through a set sequence

of positions, such as left - neutral - right - neutral - left -

etc. Usually the power to move the surfaces comes from a twisted

rubber band, and this power is controlled by an electrical magnet,

which in turn, is controlled by the receiver.

Actuator - an electro-magnetic device utilized

to move the surfaces in proportional control systems. Most of them

have a rotating permanent magnet, with some sort of electrical winding

to move it.

Servo - These are usually electric motor-driven

units, with a gear reduction system to increase power and reduce

speed of the operating arm. Often fitted, with limit switches, which

open the motor circuit at predetermined points either side of center.

May also have centering switches to return the control arm to neutral

when the signal is cut off.

Keyers and Pulsers - control boxes attached

to the transmitter, which send the correct length and spaced pulses

to actuate proportional control equipment in the model.

Beep Box - an automatic switching device connected

to the transmitter which sends the necessary pulses to work an escapement

in the model. Even though the escapement may require full sequence

operation, the Beep Box allows the operator to get successive right

or left turns in any number he wishes.

Not so many years ago, things were very simple; almost every

model was fitted with an escapement, and the only control in wide

use at the transmitter was a plain pushbutton. Things have really

progressed since then! Below is a quick rundown of the various new

types of equipment that you can purchase today; it will be seen

that there is no longer a sharp dividing line between the different

sorts of mechanisms.

Escapements. You can no longer visualize these

units as something to which you must attach a rubber band. We now

have them powered by clockwork and also by electric motors; the

latter, incidentally, are called "servos" by the maker, further

confusing things! The deBolt "Multi-Servos" are really electric-motor

driven escapements, and are made in four types as seen in the chart.

The traditional type of strictly sequence escapement is still

in wide use, and is the lowest-cost style to be had. Most of them

have two control positions and two neutrals, and you have to hold

the signal on as long as you want the control surface to be held

off center. This is considered a safety feature in some ways, since

if your model gets out of range the control surface returns to -

or stays in - neutral. This type of escapement is generally called

a two-arm type.

Three and four-arm escapement have been used, but are not widely

popular, and only a few of the latter are sold at present.

The first commercially available escapement that removed the

sequence requirement was the Bonner Compound, with which you can

get any number of rights or lefts at will; the surface is always

centered when the signal is cut off. This unit offers another feature

- third position in which a set of electrical contacts is closed,

allowing a very simple means of working a second escapement for

elevator or other auxiliary control action.

It is interesting to note that the Dmeco Model 3PN affords the

same features - that is, two rudder control positions, plus a set

of contacts that may be closed at will, to work another control.

Several multiple-type escapements have been marketed which can

control two surfaces, such as rudder and elevator; they require

close attention to the proper number and spacing of pulses and are

usually utilized with a special switch at the transmitter. The ECCO

Multi-Position escapement is an example; it has two control shafts

that may be linked to rudder and elevator, but uses only a single

rubber band for both surfaces.

Actuators. There are two forms of proportional

control in use: one - which we usually term "semi-proportional"

-allows only left, right and neutral control positions; full proportional

allows the operator to have any control position he wants, from

full right to full left. No sequence is involved in either, of course.

The equipment in the model is the same for either, the difference

being at the transmitter control box, or pulser.

Proportional actuators may be of several types, the most widely

used being fitted with a shaft-mounted permanent magnet, which is

caused to move by one or more electrical windings. Again, the most

widely used type has no other iron in it besides the magnet itself

(and possibly the shaft); this type is available from several concerns

and is, in some cases, very inexpensive. One example of the "iron

pole" style of actuator on the market is that made by Adams.

Some actuators have only a single winding, and require two sets

of batteries to get right and left deflection. Others have dual

or center-tapped windings, which can give the same results with

a single battery. In both cases, a receiver relay with single-pole

double-throw contacts is usually required. Even this latter is not

universal, though, for certain actuators are made to pull only one

way, the return motion being obtained from a spring of some sort.

The Flyball actuator is an example of this design.

The Ace High Resistance actuator is connected right into the

plate circuit of the receiver tube, thus eliminating the sensitive

relay and also the power supply needed for the normal low resistance

actuator.

Also in this field is the Fenners-Pike actuator; an electric

motor-driven unit which has a means incorporated for obtaining a

second control action, when wanted. Both controls may be worked

at the same time. As with other styles of electric-motor-driven

mechanisms, this one has considerably more pull than the strictly

magnetic type.

Servos. Servos on the market are powered by

small electric motors. Some are fitted with limit and centering

switches, others are not. In general, the units with both limit

and centering switches have been used for elevator control, while

those with only limit switches work the rudder. Limit switches are

always fitted, however, as they open the circuit when the

control arm reaches an extreme position off-center, and so prevent

jamming of the gearing; connections are such that opposite rudder

(or elevator) will always bring the surface back to center.

Lately, more and more flyers are using what is called "trimmable

elevator," which means simply that the elevator stays where the

operator puts it and does not automatically go back to center when

the control signal is cut off. This system is a lot harder to learn

to fly properly, but offers much more flexibility in aerobatics,

flying in the wind, and so on.

The Bonner servo, which is specified and sold with the Babcock

multi-control system, has no limit or centering switches; the latter

are not required, since the makers advise the use of a trimmable

elevator. Limiting is handled by mechanical stops and a slipping

clutch in the drive gearing; when either limit position is reached,

the operating arm stops moving, but the motor continues to turn.

Keyers and Pulsers. These are made in three

main types, the relay type, the electronic and the mechanical. All

have their own pros and cons. The relay types do not require any

tubes, and many of them are little more than a relay, an electrolytic

condenser and a variable resistor. A source of high voltage is required,

sometimes tapped off the transmitter B battery. Current drain is

quite low and small batteries of 45 V. or so may be carried in the

same case. Chief disadvantage of this type is that the pulse speed

varies as the pulse length is altered - a condition that is troublesome

in some cases and not in others.

The electronic pulsers have one or more vacuum tubes, and hence

require both A and B power. They are somewhat more flexible than

the relay type, and usually the speed and spacing of the pulses

may be varied quite independently of each other. With miniature

battery tubes, power requirements are low and all the batteries

may be put in the pulser case. A relay is always used to connect

the pulsing circuit to the transmitter.

The mechanical type is felt by many to be the most reliable,

but ia the toughest to make and often quite noisy. An electric motor

is geared (or belted) to a set of rotating contacts, with a control

lever arranged so that the pulses may be varied in spacing. Since

battery motors are normally fitted, quite good life may be had from

flashlight cells, and these are sometimes carried in the pulser

case. The PRC-100, Stanco and Fenners-Pike are good examples of

this type.

One other motor-driven unit should be mentioned, the Rite-Control

Pulsequence box, which afford both rudder and elevator operation

on the model; a single 2-arn escapement is all that is needed in

the plane, but since it is stepped around continuously, it must

be fitted with a long rubber band. Rudder and elevator may be applied

separately or together and in any degree and combination.

The control box comes with an extra contact plate, which when installed

allows it to be used as a regular proportional pulser.

Some manufacturers have adapted various sorts of rotary switches

for transmitter control. The ECCO dual escapement is stepped through

its paces by such a switch, and Gyro lists a Beep Box, which is

a rotary switch so made that it can be turned in only one direction,

and will step a regular 2-arn escapement around to the desired control

positions as fast as you can turn it.

To our knowledge, there are no motor-driven Beep Boxes on the

market, though a few custom-made jobs may be had.

From the above it may be seen that the complexity of control

equipment is increasing. Enterprising builders combine various of

the units mentioned above and in the chart, to get all sorts of

special arrangements. Of course, many of the units we have presented

are equally useful for boat and other model purposes; for such use,

the electric motor-driven equipment is preferred, due to the greater

force needed to move boat rudders or car wheels.

Radio Control Equipment

c1955

Posted February 23, 2014

|