[Table of Contents] [Table of Contents]

These articles are scanned and OCRed from old editions of the The Saturday Evening

Post magazine. Here is a list of the

The Saturday Evening Post

articles I have already posted. As time permits, I will be glad to scan articles

for you. All copyrights (if any) are hereby acknowledged.

|

Ask any American

what is his all-time favorite World War II fighter aircraft and the answer

will most likely be the P-51 Mustang. It's sleek lines, rocket-like speed, and the

guttural roar of its 12-cylinder engine creates a demanding presence whether in

a museum or on an airshow flight line. That same person would also probably name

the AT-6 Texan as his favorite trainer of the era, and the B-25 Mitchell as his

favorite bomber. What do all three have in common? They were all designed and manufactured

by North American Aviation. At the helm of the company during the era was James

Howard "Dutch" Kindelberger. This story from a 1949 edition of The Saturday Evening

Post magazine takes a look at the man behind those legendary aircraft, and

gives a singularly good example of how management of a production facility

should not panic and take to "throw

it at the wall and see if it sticks" approach.

Merchant of Speed

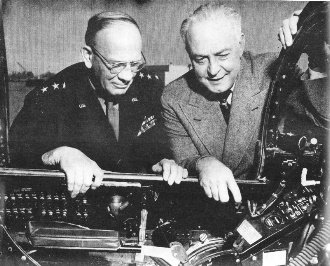

Kindelberger shows General Whitehead,

boss of Far Eastern Air Force, cockpit of the F-86, which holds world mark of 670.9

m.p.h., combat-loaded.

By Wesley Price

Dutch Kindelberger, the hustling big chief of North American Aviation, has turned

out more - and faster - warplanes than any other man on earth.

James Howard Kindelberger, chairman of the board of North American Aviation,

Inc., and perhaps the foremost salesman of warplanes this side of the iron curtain,

has allowed his baptismal name to get lost in the pages of Who's Who. Boy and man,

he has pleased to call himself "Dutch" Kindelberger. Using this handle, he commands

22,000 employees and a $380,000,000 backlog of plane orders, demonstrating, as Ike

Eisenhower has done, that a nickname is no bar to success.

Dutch builds military airplanes, nothing else. He built more military planes

than anyone else on earth in wartime. He is building them in large quantities today,

and he expects to go on building them until peace breaks out all over. He is the

only airframe magnate with a full line of trainers, fighters and bombers, who manufactures

no air liners, no private planes - although he did once - and positively no aluminum

kitchenware.

The pots-and-pans business tempted airframe companies on V-J Day, when the market

for warplanes dropped dead. Erstwhile speed merchants stood ready to produce anything

that was legal, and made of metal. Members of the Aircraft Industries Association

were test-flying frozen-food lockers, stainless-steel coffins, artificial limbs,

tractor parts, kitchen stoves, truck bodies, dishwashers, tricycles, razors, scooters

and canoes. Most of these dodges lost money. Dutch Kindelberger spared himself the

double humiliation of making pots and taking losses by thumbing the pages of Sears,

Roebuck and Montgomery Ward catalogs.

Cluster of Dutch's beauties. From left: The XAJ-1 attack bomber; the F-86, of

which the Air Force has many on order; the B-45 four-jet bomber.

As Kindelberger drives into his yard, an ultrasonic whistle on the bumper alerts

a robot ear above garage door, activating the door-raising mechanism.

More bacon and eggs? Mrs. Kindelberger transmits the order to the kitchen over

an intercom. Scores of electric motors perform various household tasks.

"Here," he told his staff, "are most of the world's consumer goods, described

and priced. Let's see what we might manufacture at a profit."

Skipping the section on ladies' underwear, Dutch and his lieutenants pored over

hundreds of offerings, from Abrasive Wheels to Zithers. When they came to something

good, like ash buckets or ironing boards, they figured production costs. Their"

bids" for North American ran 30 percent higher than the mail-order prices.

The Sears, Roebuck seminar was held in 1944, at the peak of the war boom. It

convinced North American's bosses that precision-tooled aircraft plants were ill-suited

to cheap mass production. Dutch gave postwar plans a wave-off, saying, "They won't

pad our butts for the fall we have to take."

Some of Kindelberger's offhand remarks are suitable for engraving, and they lose

nothing in the delivery. In a voice that rumbles like a kettledrum, he urges his

men to speed delivery of new jet models, "An airplane is like an egg. It has to

be sold when it's fresh." His dictum on how to assemble aircraft - Don't let them

get too big too fast" - is widely quoted in an industry that once hired midget riveters

to work inside bomber wings.

Naval intelligence was puzzled recently by news leaks concerning a North American

bomber. Dutch might have pointed out that the ship was parked at the Los Angeles

municipal airport in full view of thousands of sight-seers. All he said was, "We

have never found a good invisible paint for our airplanes."

Dutch has no Boswell embalming his words for the ages, but his cronies have been

known to put a wire recorder on him when he was wound up. They can quote Kindelberger

on world peace: "There are piles of gunpowder all over the world, and people playing

with matches"; Kindelberger on Californians: " You become a native the day you sell

your trailer"; and Kindelberger on labor relations: "If the men in the shop are

happy in their jobs, it is surprising how many more times they can hit something

with a hammer than if they are sour about it."

Admirers are apt to credit Dutch with the pithy maxims of Anon., our national

wit. Also, he borrows freely from others. It was probably Edgar Schmued, assistant

chief engineer of North American, who coined the classic directive for streamlining

airplanes: "Get all the humps and bumps inside."

Then there is Dutch's view of lint-picking perfectionists who delay production.

"It takes two men to make an airplane drawing," he has said," one to sit on his fanny

and draw lines, the other to knock him on the head with a baseball bat when he's

through." Dutch claims he was paraphrasing Lee Atwood, president of North American.

The ribald tone, however, is authentic Kindelberger.

Atwood is a lean, drawling Texan who has shared Kindelberger's ups and downs

- mostly ups - for nearly twenty years. He stepped into the presidency of North

American last summer, when Dutch was elevated to the board chairmanship. Their worst

times came at war's end, when the Air Force canceled huge orders. A thin paste of

experimental work remained, too weak to hold a great corporation together. Overnight,

the entire airframe industry loosened at the joints.

What to do? The Kindelberger-Atwood team had an air liner on paper, but the drawings

were years out of date, development might cost ten to forty millions, and competition

was stiff. Twin-engine sales were being shared by Martin's 2-0-2 and Consolidated

Vultee's Convair-liner. Douglas was coming out with the DC-6; Lockheed offered a

new-type Constellation; and Boeing was taking cash deposits on double-deck Stratocruisers.

Meantime, air line barons had been mooning over market surveys which forecast

a great boom in air travel The surveys were wrong. In consequence, air lines ordered

far too many ships. Then, soberly counting their passengers, they canceled nearly

half of the orders. Some of the manufacturers had to eat development costs, dulling

the pangs with massive doses of tax-carry-back credits.

Dutch Kindelberger let other firms have the air-line business. He closed factories

in Texas and Kansas, beat a retreat to North American's home plant, alongside the

Los Angeles airport, and set engineers to designing new warplanes. This move kept

a priceless staff from disintegrating. By 1947 Dutch had two jet fighters and a

jet bomber in test flight. By 1948 Russian policy had jolted Congress, the armed

forces were shopping with fresh millions, and behold, there was Dutch, lugging a

full sample case.

But a long dry spell intervened; North American lost 87,000 workers from war's

peak to the bottom of the peacetime slump.

The 5000 survivors included men who had taken demotions and laid away white shirts

with "Foreman" emblazoned in blue letters. Dutch gave a dinner for the die-hards,

saying "Don't throw away your foremen's shirts, boys, you're going to need them

again."

North American suddenly put a four-place private plane on the market. Officially

dubbed the Navion, it was known in the shop as "The Baby." Dealers begged for doubled

quotas. Production rose to ten a day, until 1100 Navions had been built. All at

once the suction vanished. The market analysts, wrong again, had grossly overestimated

the demand and underestimated prices.

Government bureaus guessed we would have 450,000 private planes by the year 1950.

So far, we have about 96,000. Prices were forecast between $1500 and $3000. The

N avion, built to opinion-poll specifications-four seats, retractable gear, 150-miles-per-hour

speed-started at $6100 fly-away-factory, and quickly went to $7500. A friend told

Kindelberger that he would like to buy a Navion at cost.

"Write the check," said Dutch, "and make it for ten thousand dollars."

North American eventually sold all Navion manufacturing rights to the Ryan Aeronautical

Company, which now makes the Ryan Navion. When the armed forces looked around last

year for thousands of new airplanes, Kindelberger's vast production bays were wide

open. He had the men, the tools and the jet samples. Few were surprised that he

won a lion's share of the military contracts, and if anyone murmured that Dutch

once more had pulled a rabbit out of his hat, he had an answer: "You can't pull

a rabbit out of a hat unless you carefully put the rabbit in the hat beforehand."

North American's postwar rabbits include the Navy jet fighter FJ-1, first to

have a straight ram duct; the Air Force's B-45 bomber, first four-jet plane ever

built; and the F-86 fighter, faster than anything else in production. The F-86 holds

the official world's speed record at 670.9 miles per hour with a combat load of

gas, guns and ammunition. Unofficially, it has flown faster than sound. Now there

is an even faster model, designated the F-93A. The Air Force has many of both types

on order.

The President's Air Policy Commission reported last year that national survival

in the air age required a strong aircraft industry in being. Kindelberger detected

the musty odor of Government subsidy and discharged a refreshing blast of ozone:

Let lazy companies starve to death, he advised the commission; keep alive only those

companies which would fight for contracts with superior planes, prompt delivery

and low prices.

Such concern for the American taxpayer is rare indeed, but one must not conclude

that Dutch is prepared to make a blood sacrifice of his stockholders. The fact is,

he favors ding-dong competition because he expects to win. He takes pride in North

American's new T-28 trainer because, in an Air Force contest, it beat out designs

submitted by twelve other firms. As an engineer, he boasts that the wartime P-51

Mustang excelled all other fighters in speed, range and ceiling. As a salesman,

he points to the bargain price tag. Mustang frames sold as low as $17,200; all other

fighters cost more and flew slower.

Kindelberger minds his engineering and refrains from sounding off to the press.

Assuming that our need of air power is obvious, he is disinclined to give the public

a tin ear on the subject. He is silent on Russo-American tension, leaving the task

of advising the State Department to nuclear physicists, radio oracles and sententious

bartenders. Dutch talks about things he knows for sure: factory methods, European

versus American; orchid growing; outdoor cookery; workmen's troubles.

He started working as a steel-mill laborer in Wheeling, West Virginia, where

he was born in 1895, and where his parents still reside. His father was a molder.

Dutch quit high school in his second year to earn five dollars for a , six-day week.

He studied correspondence-school lessons at night, taught himself mechanical engineering,

and became a civilian draftsman for the United States Army Corps of Engineers. By

the age of twenty-one he had crammed enough homework to pass entrance examinations

for the Carnegie Institute of Technology.

Dutch Kindelberger paid his own way, nursing $300 he had saved, and quieting

appetite with buttermilk at five cents a glass; soda crackers were free. He left

Carnegie after a year. His $300 was intact, and he had a buttermilk thirst which

is not quenched yet.

During the first World War he rose from private to lieutenant, learned to fly

in the Signal Corps, and became an instructor. He was not outstanding as an aviator.

A month after Armistice Day, 1918, he landed a job as draftsman in Glenn L. Martin's

aircraft plant in Cleveland. His boss there was the chief engineer, Donald W. Douglas.

Dutch eked out a $27.50 pay check by teaching night classes in aviation, processing

photos in his bathroom, drafting freelance for inventors, and writing how-to-do-it

pieces for a scientific magazine. By 1920 he had risen to assistant chief designer

for Martin. Don Douglas resigned to found the Douglas Aircraft Company in Los Angeles.

Dutch was invited to go along, but he postponed the move five years. "Had to save

up the railroad fare," he says.

He helped Douglas pack up. Technical publications covering the entire science

of aeronautics fitted into two small cartons. Nowadays two cartons wouldn't hold

the bibliography; the Air Force is shrinking mountains of technical literature with

micro printing and microfilm.

"Up to the year 1930, I could carry in my head practically all you had to know,"

Kindelberger says. "Now we have subdivided specialties. We have people who work

on flutter - nothing but flutter. We have six kinds of aerodynamicists, including

internal aerodynamicists, who study air's behavior in the ducts of jet engines.

If an internal aerodynamicist bungles, your airplane is a cluck."

Kindelberger was newly settled in his job with Martin, after the Armistice, when

an order for 1000 bombers was slashed to ten. He saw skilled mechanics playing volleyball

on an empty assembly floor. While the industry languished, the armed forces designed

and built planes themselves, which Dutch describes as "boiler-plate

monstrosities." Foreign planes got so much better than ours that a law was passed

to squelch Army-Navy whittling and encourage private bidding for contracts. Everybody

got a little work. Aviation shares rode the stock-market boom of the late '20's.

"There were three hundred factories by 1929," Kindelberger recalls, "including

those where you had to shove the cow aside to see the airplane."

Investors paid more than $300,000,- 000 for pieces of paper embellished with

pictures of airplanes. A good half of the money was wasted, but the balance financed

a revolution in design. Wood and fabric gave way to steel and aluminum. Exposed

struts and wires vanished. Ships brought forth by Boeing, Northrop and Lockheed

had the New Look. Donald Douglas unveiled the first of his great family of DC air

liners. Engineering on the DC-1 and DC-2 was supervised by Dutch Kindelberger, who

joined Douglas in 1925. He stayed there nine years before going to North American.

North American Aviation, Inc., was formed as a holding company in 1928, a year

of easy money and grandiose ideas. Its rival combines were United Aircraft and Aviation

Corporation. These three engorged most of the air lines and aviation industries

in the country. General Motors soon controlled North American, which held in its

turn a score of airline, airframe, engine and instrument corporations, some of which

had devoured smaller firms.

In 1934 Congress told the boys to break it up, slightly. The name" North American"

was salvaged and applied to a moribund grouping of airframe enterprises. Dutch Kindelberger

signed up as president. He detached Lee Atwood from Douglas' engineering department

to serve as vice-president. They left sunny California, went to humid Maryland and

viewed the remains. North American was a gloomy building near Baltimore, enclosing

the skeleton of an outmoded trimotor transport.

The shop had a tiny order for trainers. There was a fighter that didn't fly.

Not more than seventy-five trained mechanics and engineers were in the place. Many

were Dutchmen, brought here by Tony Fokker, Holland's great designer. The Fokker

company, of course, had been folded into North American.

Kindelberger junked the trimotor air liner. He made preliminary freehand sketches

for a military trainer and all observation plane. He had nine weeks to build the

trainer for an Air Corps competition. In those days the blue-eagle NRA limited the

workman's week to forty hours. Kindelberger called his Hollanders together. "No

overtime," he warned, "or I'll be in the hoose-gow."

One night he found the plant all lit up. There was an uproar of pounding, yelling

and singing.

One of the Dutchmen explained, "After eight hours' work we ring out and go to

Helen's place for beer. Then we come back and have fun getting the job done. There's

no law against having fun."

So they won the trainer competition of 1935, and a quantity order. The observation

ship sold too. Kindelberger resolved to move North American to California and take

his fun-loving craftsmen along. He had trouble persuading them.

"There were rumors about hostile Indians west of Pittsburgh," he says. "I fed

them beer and crab cakes, and lectured on the marvels of the West."

The whole gang migrated to a rented factory near Mines Field, now the Los Angeles

airport. Trainers were their bread and butter for years. The matured design, best

known as the AT-6, became the military standard in thirty-three countries. Soon

North American was selling more planes abroad than at home.

Kindelberger visited Europe in 1938 to boost sales and to see what foreign engineers

were up to. He was in London when Hitler was appeased at Munich. Dutch toured aircraft

factories in England and Germany, and found out why Chamberlain could do no more

than wave his umbrella. What he saw, long hushed up, may now be summarized.

He found only eight Spitfires assembled in England; two were in flyable shape.

In Germany he inspected production lines that were clicking off 1000 planes a month.

His comparisons of factory techniques shocked insiders. German engineers designed

for quick, easy manufacture; British engineers didn't.

The Spitfire's lovely elliptical wing, for example, caused too many workmen to

spend too many man-hours bumping out compound curves. Moreover, well-meant advice

from British motorcar experts had made matters worse. Their automotive tooling was

all wrong for airplane production. Expensive auto-type dies, made to knock out 100,000

identical parts, were outdated at birth by swift changes in airplane design. Kindelberger

saw the dies rusting in junk heaps.

He whipped over to Germany and looked up the late Ernst Udet. In pre-war days,

Udet was a famous stunt pilot who met leaders of American aviation at air shows

here. Now he was a big wheel in German warplane expansion. Kindelberger asked him

for passes to the factories. He was shown not only the factories but secret research

laboratories as well. Kindelberger was the first foreigner to set foot in the Messerschmitt

plant. Later he guessed the reason: Udet hoped the American engineer would tell

Nazi brass hats that good old Ernst was doing a grand job.

Little escaped Kindelberger's eye. He noted that airplane designs were cunningly

adapted for simple tooling.

Machinery and plant layouts were superb. The Heinkel factory reminded him of

his own in California. A German engineer admitted that American methods had been

copied. Dutch saw that a single extra shift would double production to 2000 planes

a month; he visited schools where the reserve workers were in training. After ten

eye-popping days, he returned to London. There he made pointed remarks in the proper

quarters and pocketed an order for 200 trainers.

The trainers were delivered so fast that the pleased British asked for fighters

too. North American had none. The British said that copies of the obsolescent P-40

would serve. Kindelberger and Atwood did some scratch-pad figuring and made a counteroffer:

they would layout a brand-new plane, undercut the P-40 price and fill orders in

record time.

Edgar Schmued took over the preliminary design. One hundred and twenty-seven

days after his first pencil stroke, a P-51 Mustang stood on the floor, wanting only

its engine. Flight tests disclosed top speeds that the British disbelieved and put

down to Yankee boasting. Hence they gave P-51's meek reconnaissance jobs - until

Spitfire fighter pilots complained that Mustangs were whizzing past them over the

Channel. Later triumphs of the P-51's over Berlin and Tokyo of course are too well

known to need recounting.

Only three military types bore the North American label during the war: the AT-6

trainer, the P-51 and a blue-ribbon medium bomber, the B-25. Dutch Kindelberger

lived partly in a B-25-speeding between his plants in Los Angeles, Dallas and Kansas

City, Kansas - and partly in hotels. In his mind's eye he had a dream house. He

put it all down on graph paper, bit by bit, as he rocked along beside his pilot.

The house now stands atop a high palisade overlooking the Pacific Ocean. Dutch

was his own contractor-architect. The result is a home owner's delight and an engineer's

paradise. Hundreds of electric motors are buried in the structure. The orchid house

humidifies itself automatically. Guest beds retract into a study wall. The porcelain

chill of bathtubs yields to overhead heat lamps. A pilot's microphone behind the

bar lets Kindelberger ask the kitchen for ice; a wall panel twirls; Roger dodger,

there's the ice. A storage wall with sliding panels holds every stitch of family

clothing, and every stitch was carefully measured before Dutch shaped the drawers.

He bought an automatic garage-door opener. A magnet on the approaching car actuated

a tip switch in the concrete driveway. A motor whirred and the door rose. Sometimes

it failed to work. So he put a radio transmitter in his car, one mouse-power, and

a receiver in the garage. Pressing a button on the car's, dash signaled the door

to move. One night in Washington, Kindelberger had a long-distance phone call from

his wife, Helen. "The door is going up and down, up and down, up and down. Oh, Dutch,

what can I do?"

Kindelberger guessed that a radio ham was sending on his garage-door frequency.

He discarded the transmitter. Now he has an ultrasonic whistle on his front bumper.

Too high-pitched for human hearing, it alerts a robot ear on the garage. The ear

notifies an electric motor that Dutch wants in; the door rolls up. It can be whistled

down, too, and it always works.

Six months of cut and try went into those doors. Dutch cites that fact to suggest

why years of effort go into airplanes. New models are substantially redesigned three

times before they pass tests. You install a clear plastic canopy, for example, which

resists a ton of pressure per square foot. The pilot flies at 600 miles an hour

through rain, and your fine canopy is chewed up by water drops.

The engineering problem increases as the cube of the speed. A prewar North American

bomber took 103,000 man-hours to design and test. The new B-45 jet bomber, about

the same size, has used up 1,000,000 engineering man-hours so far, and needs an

estimated 237,000 hours more for polishing.

To plan for next year's airplane is shortsighted. Kindelberger looks three long

years ahead. He guesses what speeds will be wanted in 1952; what tactics will evolve

by then; what engine powers will be available; what gadgets and plumbing and spaghetti,

not yet invented, will have to be fitted into planes not yet born.

At the back of his mind, he knows that he is trying to outguess Russia. Nearer

the surface is his powerful urge to outguess and outsell the airplane store down

the street. He was toasted recently at a dinner celebrating his thirtieth year in

the industry. Responding, he told the distinguished company, "We will all go on

doing our best." At another party, for North American foremen, he was more explicit

. "There is nothing I like better," he said, "than being up to my tail in business."

Posted December 4, 2023

(updated from original

post on 2/3/2013)

|