|

Here is the article and plans for the Piel Emeraude that I electronically

scanned from my purchased copy of the April 1969 American Aircraft Modeler

magazine. Because they span two or more pages, I had to adjust the size

and alignment a bit to get halves to line up properly. You might be able

to scale up the image below. Plans for this fine model were drawn by Mr.

Bob Morse. All copyrights (if any) are hereby acknowledged.

"The Piel CP-30 Emeraude is an aircraft designed in France in the mid-1950s

and widely built both by factories and homebuilders. It is a low-wing cantilever

monoplane with fixed tailwheel undercarriage and side-by-side seating for

two. The prototype was designed and built by Claude Piel."

- Wikipedia

Piel Emeraude Article & Plans

The May, 1964, issue of Experimental Aircraft Association's Sport Aviation

magazine carried an article describing the Emeraude, designed by Claude

Piel of France and built by Wayne Barton of Rush, N. Y. The May, 1964, issue of Experimental Aircraft Association's Sport Aviation

magazine carried an article describing the Emeraude, designed by Claude

Piel of France and built by Wayne Barton of Rush, N. Y.

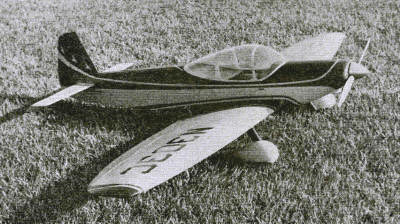

Popular French-designed home-built makes an ideal R/C ship capable of

AMA pattern maneuvers, including snap-rolls and inverted spins.

BOB MORSE as told to Leon "Duke'" Crow

After seeing the photos of, this beautiful home-built aircraft, we had

to duplicate Mr. Barton's marvelous ship for R/C. We obtained from Falconair

Aircraft Co. of Edmonton, Alberta, Canada, a descriptive brochure and three-view

drawings.

The Emeraude is quite an airplane, having a wing span of 26 ft. 4 in.,

length of 21 ft., and a wing area of only 117 sq. ft. It can tote two adults

at a maximum speed of 112 mph, or cruise at 103 mph on only 65 hp. Increasing

the power to 105 hp jumps the cruise speed to 120 mph and maximum speed

increases to 137 mph.

The cost of building a ship at home can be difficult to nail down. Mr.

Barton man-aged to build his Emeraude, using all new materials except for

instruments, wheels and a majored engine, for only $1,223. This is really

a lot of airplane for the money! We plan, someday, to begin construction

of our own Emeraude, but until then, we will have to enjoy our model.

The real plane also is an exciting aircraft. Clean

lines give fast cruise performance. Large wing area permits slow

easy landing. Model's airfoil also permits aerobatics.

Since building the ship in 1964, we have enjoyed many many flights. It

is an excel-lent flyer, very stable and will perform the complete '68 AMA

pattern (including snap rolls and inverted spins) maneuvers. And you wouldn't

believe the ground handling; takeoffs and landing have to be seen to be

believed with these old-fashioned bicycle landing gears.

Wings: Construction is straight-forward and should present no

problem. While the wing appears difficult to build because of its

elliptical shape, it is, in reality, a straight wing with only the

outboard portion, incorporating

the ailerons, being elliptical. We chose the full-depth spar with inter-locking

ribs as the most practical method of obtaining the elliptical wing shape

and to provide the, correct spar profile in the outboard section of the

wing.

Begin construction of the wing by pinning the inboard trailing edge

Sheet to the flat building board. The main spar with the ribs keyed loosely

in place is then placed on 3/8" square spacer blocks (you'll see the reason

for this when you pin the ribs down to the bottom trailing edge sheet).

With the loose assembly in place, key the outboard ribs in place and then

position the aileron spar so that all ribs are in line. With this spar pinned

and blocked in place, the ribs can be disassembled and, reassembled with

glue. After the glue has taken its permanent set, the leading edge, nose

sheeting and trailing edge sheeting can be installed. Add the rib cap strips

and, when the assembly has cured, lift the panel and add the landing gear

blocks, lower nose sheeting, and lower cap strips.

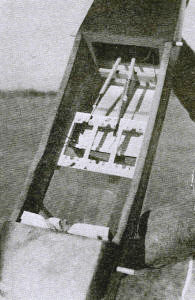

Looking through wing opening and out the canopy from the inside. There's

plenty of room for three large servos side-by-side.

Inverted engine easiest to start. Don't prime into cylinder; just wet

side of piston with fuel just before flipping prop.

Wheel pants.

Repeat this for the opposite panel and you are ready for wing joining.

Sand the skin sheeting at the roots to the dihedral angle shown and butt

glue the two panels together. Take all the time you need at this point and

make absolutely sure that the two panels are perfectly mated. If you do

this right, you will have a wonderful flyer. Do it wrong and you'll have

a dog! Assuming you have done it right and your glue has set, paint a 2"-wide

strip of resin around the center-section joint, press a strip of glass cloth

into the resin, and finish off your basic wing structure with a final coat

of resin over the cloth.

The ailerons are built now and can be either built-up as shown, or hogged

out of soft 3/4" sheet stock.

Fuselage: It is rather straight-forward and should present no problems.

Start by making two complete side assemblies; don't forget, one right-hand

and one left-hand. These consist of the 3/32" side sheets, the ply wing

opening doubler, the vertical 1/8" x 3/8" stiffeners and the stringers.

After these have been finished, gently crack the 3/32" sheet at the forward

edge of the ply doubler as shown in the top view; this will make things

a little easier later on. Assemble the fuselage upside down on the building

board with the front hanging over the edge of the board so that the firewall

and the fuel tank bulkhead can be installed. Add the gusset blocks and engine

mount beams, then add 1/8" x 3/8" cross pieces at the uprights and top of

sides, then the 3/32" bottom sheeting.

Pick up the fuselage now and complete the rounded, stringered top. To

get straight stringers, pre-notch only the aft cabin former and install

the other three turtle deck formers without the notches. Position each stringer

as shown and mark the position on the rest of the formers, then cut in

the notches and install each stringer as you go along.

Miscellaneous: As the model is built to 1/5 the size of the real ship,

there is room for almost any type of radio gear. If you would like to operate

the wing flaps, there is plenty of room for the control installation.

Conventional torsion-bar landing gear used wheel pants from Stafford

Chipmunk kit with strut faired by balsa and silk wrapping. There are two

pretty hard nuts to crack in building this bird, and we will tackle the

tough one first. The cockpit canopy resembles a rather small birdbath!

There are two ways of getting a canopy on your ship: 1) carve a hard balsa

pattern 1/16" under-size from the drawing contours and finish it glass-smooth

with Hobbypoxy, or a similar hard coat, and then heat. 1/8" Acrylic or Polyvinyl

sheet to a pliable state and quickly press over pattern. The second

problem is wheel pants. We did it the hard way - made molds and laid up

our own with resin and cloth. Our next ship will have Jack Staffords' fiber-glass

Chipmunk or the Williams Bros. plastic parts.

As far as power is concerned, the ship is an excellent performer with

a 45 mill up front, but for competition flying, a 60-size engine will really

put those rolls "on a wire." Our ship is silk covered and finished in butyrate

color in the same scheme as Mr. Barton's N9441H.

Every construction article we've read has cautioned the new builder to

check things out before you go down to your favorite 5,000-ft. runway. We're

no exception. Almost is not good enough. It's got to be right. Check out

your control system. Recommended ground range, control linkages free, vibration

checks with engine running, and so on. If anything doesn't look quite right,

fix it now, or you won't have anything to fix later. Flying: An experienced

flyer will have no trouble with the Emeraude. One word of caution to our

hot-dog tricycle-geared pilots, take it easy on the throttle on take-offs.

Ease her up to about half throttle and watch the tail lift off. When she's

got some speed and the controls---become effective, you can firewall the

throttle and really go!

We have flown the trike-geared ships for a long time now, but two-wheel

lift off and touchdowns of a bicycle gear really give you a thrill.

For the new R/C flyer, Emeraude is a gentle, forgiving ship, and with

an experienced flyer as a copilot, she makes an excellent trainer.

If you would like to get into the scale competitions, here's your chance

to grab a few points with a relatively easy-to-build dependable flyer.

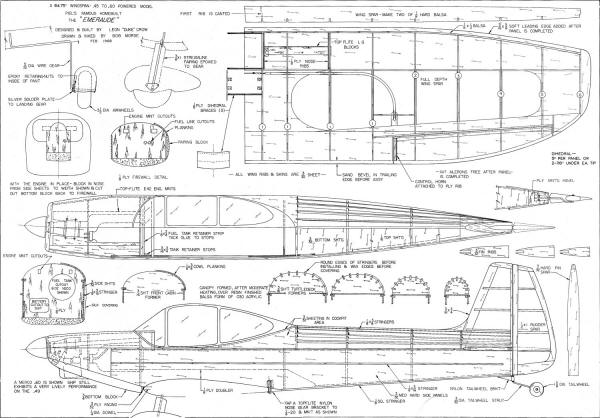

Piel Emeraude Plans Sheet 1

Piel Emeraude Plans Sheet 2\

Piel Emeraude 3-View

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

|