|

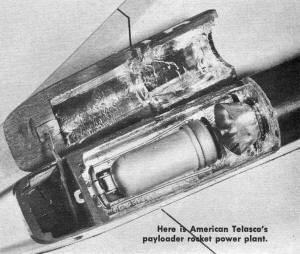

This rocket boost

glider called the Dyna-Soar was powered by

American Telasco's version of the

Jetex 50 engine. Jetex rocket

engines were quite popular with model airplane, boat, and car builders through the

early 1970s, at which point the fuel supplies began to disappear. Most Internet

sources posit that

Imperial Chemicals Industries (ICI) ceased making the fuel pellets

due to a combination of liability and regulation issues. ICI, based in Scotland,

manufactured the

Jetex fuel pellets* from a measured blend of guanidine nitrate,

2,4-dinitroresorcinol, potassium nitrate (aka saltpeter), iron oxide, kaolin, and

asbestos. Today, obtaining the required chemicals, or even doing an Internet search

for them (as I just did), will probably get you a big red flag in the Department

of Homeland Security's database. There are probably a couple agents on the way to

my house as I write this.

* See the

Jetex Propulsion Lab for a incredible bit of information on the

motors and the fuel.

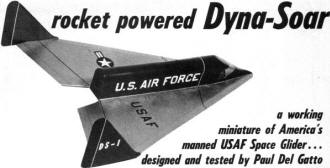

Rocket (Jetex) Powered Dyna-Soar

Designed and tested by Paul Del Gatto Designed and tested by Paul Del Gatto

Dyna-Soar, the manned space glider, is an incredible flying machine. Compared

with this Mach 25 terror, even the famous X-15 is a toy. Boosted aloft by a Martin

Titan, it will combine the high speed of the ballistic missile with controlled,

accurate flight of manned aircraft.

Dyna-Soar's pilot will shorten or lengthen its range by thousands of miles, changing

course to reach a landing site. He can choose fields as far apart as Point Barrow,

Alaska and San Diego. Able to operate subsonic, transonic, supersonic and hypersonic,

Dyna-Soar will be capable of operating like a large, fast aircraft when approaching

an airport.

Later developments of Dyna-Soar for weapons-system and escape missions and to

circle the moon will take various combinations of Saturn boost stages.

U.S. Air Force's rocket boost glider.

Boeing is prime contractor for system and the piloted glider.

Surprisingly, a model Dyna-Soar is easier to make than many a free-flight design.

Deltas like Dyna-Soar long ago demonstrated their performance and stability capabilities.

The Jetex Pay-Loader "150" rocket motor with its augmenter tube provides plenty

of push and the craft presents no adjustments problems.

Your Dyna-Soar, built as a unit, is practically complete before lifting it from

the workbench. Only the fins, part of the elevons and the landing skid remain to

be added.

Since weight and balance are important, the craft should be covered with lightweight

Silkspan tissue and colored dopes should. be used sparingly. Follow the hardnesses

of balsa specified.

Wing: Pin down 1/8" x 5/8" hard-balsa tapered leading edges

and wing trailing edge pieces, followed by medium 1/8" x 3/8" balsa center-section

pieces. Fit and double-cement in position 1/8" x 3/8" medium ribs and diagonal pieces.

Assemble built-up portions of the "elevons" using hard 1/16" x 1/4" trailing

edge pieces and medium 1/16" x 1/8" and 1/8" -sq cross pieces where required. Aft

sheet-balsa pieces (elevens) are added later.

It is important that this procedure be followed in making the elevons ... for

each elevon pin down and cement to wing trailing edge the four main cross pieces;

attach the elevon trailing edges flush with the top of the cross pieces, then the

diagonals. Elevon cross sections (on side view) are obtained later by sanding the

bottoms of the elevons cross pieces and diagonals to match the 1/16" thick elevon

trailing edges.

Fuselage: Cut formers from medium sheet balsa, noting thicknesses.

Erect formers F-5, F-5B, F-6, F-7 and F-8 on center section pieces, then slip augmenter

tube into position. Tube is rolled to shape from .005" aluminum 2-5/8" wide plus

allowance for an overlapping seam.

After erecting formers F-1 and F-2, cement in motor mount. This is assembled

from 3/32" medium balsa base (full body width) and 1/16" thick plywood overlay 3/4"

wide (to which metal motor-mounting bracket is screwed).

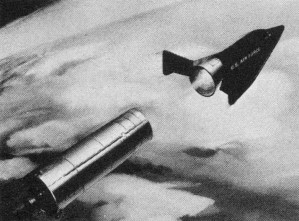

Dyna Soar will be boosted into space by modified Titan III missile

as seen above.

Before sheet covering the fuselage make sure you understand the hatch construction.

Fuselage sides are 1/16" medium balsa sheet, extending forward to 1/8" sheet fill-in

cabin nose piece. Sides are feathered together where they meet at the nose. Fill

in where necessary with balsa scraps.

Forward portion of removable hatch is carved from soft balsa block 5/8" thick.

Hatch extends to F-4. To complete hatch, insert formers F-3 and F-4 and plank with

soft 1/16" sheet. When thoroughly dry, model is removed from work surface.

Final Assembly: Add 1/16" x 3/4" soft-balsa sheet elevon pieces,

then sand smooth entire model, taking care that elevons taper from the bottom to

a thin edge at their trailing edge, as per the side view. Cut fins and rudders,

sand smooth, cement in place. Note they are offset slightly relative to centerline.

Round off leading edge pieces.

Cut air-intake holes in forward fuselage. This air flow is required for augmenter

tube to serve its purpose - stepping up thrust. Cover the holes with fine wire screening.

Shape 1/4" thick landing skid from two laminations of 1/8" sheet balsa, cement

securely in position.

Painting and finishing: Give wing framework a coat of clear

dope wherever covering will touch. For sheet-balsa fins, rudders and elevons plasticize

dope with four drops of castor oil per ounce of dope. This minimizes warping due

to dope shrinkage.

Cover wing top and bottom with lightweight Silkspan; use one piece for the bottom

and two for the top. Run grain spanwise. The fuselage is not paper-covered. For

overall doping of completed covering, use mixture of 1/3 thinner and 2/3 dope. Give

covering three coats, allowing each to dry, and each time apply a coat of dope to

the fuselage. After each of the first two fuselage coats, sand sheetwood skin with

fine paper.

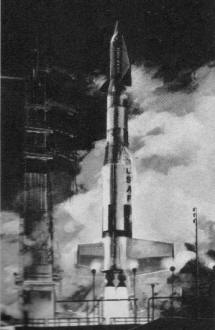

Dyna Soar launched into the wild blue yonder.

Here is

American Telasco payloader rocket power plant.

Color scheme is dark blue fuselage and silver wings. Mix colored dope with thinner

2/3 and 1/3 as before, apply two coats. Lettering and insignia trim are from hobby

shop decals.

Flying: Test glide model, launching it by the landing skid.

If tail heavy, add clay ballast to nose. If nose heavy bend up elevons slightly.

For best performance model should be trimmed with elevons raised 5° to 10°.

Make these initial tests over soft grass and avoid windy weather. Aim the model

at a ground spot about 50' ahead in these hand glides.

When flying with power point nose up slightly, launch with the same force as

for hand gliding.

Further adjustments are carried out by bending individual elevons and/or the

trim tab (note bend line) of the left fin. For example, bending up the left elevon

(looking down on the craft from the rear) will cause a right hand turn and vice

versa. Never bend an elevon down.

If more turn control is desired, or if a smoother, coordinated turn-and-bank

is needed, bend the fin trim-tab in conjunction with elevon adjustment. Thus, bending

the tab toward the center line while bending up the left elevon, coordinates both

controls for a right turn. If Dyna-Soar turns too tightly, use opposite adjustment.

Be sure to select plenty of flying space because your Dyna-Soar will live up

to its name. It climbs like a homesick angel and probably will come down out of

sight unless adjusted to circle.

Dyna-Soar Materials:

(Balsa unless otherwise specified)

One 1/16" x 2" x 36" (medium) for fuselage sides and formers; (1) 1/16" x 3"

x 18" (soft) for fuselage top and elevons; (1) 3/32" x 3" x 18" (medium) for fin,

rudder arid engine platform; (1) 1/8" x 2" x 18" (medium) for fuselage formers,

gussets and wing fill-ins; (1) 1/8" x 5/8" x 36" (hard) for tapered wing leading

edge; (1) 1/8" x 1/2" x 18" (medium) for wing trailing edge; (2) 1/8" x 3/8" x 36"

(medium) for wing ribs and diagonals; (1) 1/8" x 1/4" x 18" (hard) for elevon trailing

edge; (1) 1/16" x 1/8" x 36" (medium) for elevon ribs and diagonals.

Also: 1/16" plywood engine mount; aluminum foil liner; fine wire mesh screen

air inlet; 1/32" diameter wire; light weight Silkspan covering; Pay-Loader "150"

engine; clear and colored dopes; cement; decal; .005 aluminum for augmenter tube;

clay ballast.

Full size drawings for Jetex-powered model are on Hobby Helpers' Group Plan #762A

(85¢).

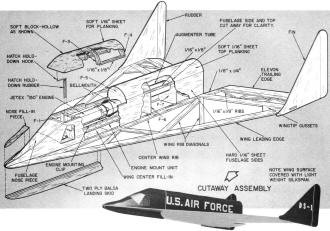

Rocket (Jetex) Powered Dyna-Soar Assembly Drawing

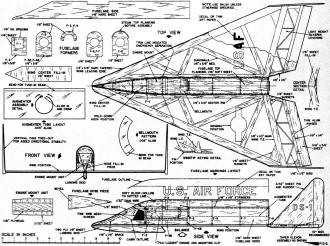

Rocket (Jetex) Powered Dyna-Soar Plans

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

|