I remember receiving my copy of the September 1973 issue of

American Aircraft

Modeler magazine with the photo of the

Sparrow RPV

on the cover. Such a thing was a big deal back in the day. It was

ground-breaking research and development for small RPVs with real-time video

feedback. There was no GPS to help guide the

airplane and flight stabilization was relatively crude. Well-known R/C modeler

and former AMA president

Don Lowe was on the team. "On Monday, Oct 19th Jim

Dalton and Doug Erhardt delivered a new aircraft to the museum, the Sparrow.

Offered by Jim and accepted by the Museum's Acquisition committee, the aircraft

was designed by Raymond Fredette of the Flight Dynamics Laboratory at

Wright-Patterson Air Force Base in the early 1970s..."

Website visitor David M. wrote

to request this article Sparrow RPV, from the September 1973 edition of American

Aircraft Modeler. The Sparrow was the forerunner to many of the world's modern marvels

of technology in the RPV - now called Unmanned Aerial Vehicles (UAV) - world. Why

"unmanned" rather than "remotely piloted"? Simple, it is because many of the aircraft

now fly autonomously for at least a segment of their missions; therefore, it is

its own pilot. Author Dave Scully could not have known at the time he was describing

the future of everything from mass produced large, prefabricated aircraft, high

displacement engines, 14"-plus propellers, and the installation of wireless sensors

in aircraft. A large (80" and 160" wingspans), heavy (25 lbs. & 200 lbs.), with

2 hp & 12 hp engines, and 16" props was a novelty back in the day, and was mostly

the realm of government-financed research projects and wealthy private modelers.

Today, dozens of manufacturers offer affordable (not by me, though) giant scale

models and a complete line of accessories. Use of more than 5 servos was virtually

unheard of, but now even some sailplanes have 6 or more. For less than $200, you

can now buy a complete wireless video system, radios include remote telemetry data

on system health as well as airspeed, altitude, engine or battery temperature, and

much more. Hobby Lobby was selling a complete wireless system (PilotView FPV 2400) for a

few hundred dollars until the FCC filed a violation order. Any day now I expect

to see a model scale synthetic aperture radar (SAR) system for 3-D terrain mapping

and remote infrared (IR) night vision. The military already has it.

Say, why didn't I get to work on this kind of a cool project when I was in the

USAF, like MSgt. Scully here?

Sparrow

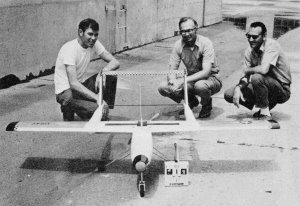

Principal members of the Teleplane Team are (left to right):

Dave Scully, Don Lowe, and Jim Cline.

Sparrow flies with 24 lb. of video equipment and both Ross 4

and Ross 6 cylinder engines. Here Jim Cline puts the starter to it while Dave Scully

holds on.

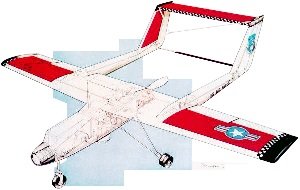

This colorful plane waits patiently for flight duty. Construction

utilizes mostly fiber-glass and foam/plywood flying surfaces.

Top view shows that a great deal of flap area is available for

slow flight work.

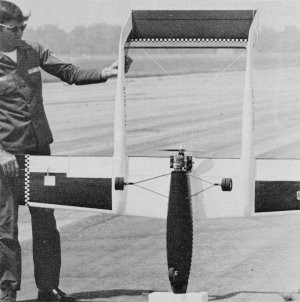

Underside, Ross 4 installed at this time. Spreader bar at tail

is streamlined K&S tubing. Rudder linkage passes through it.

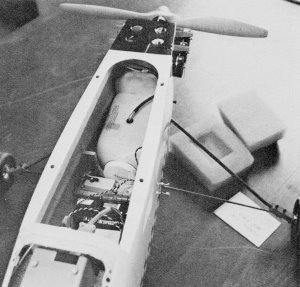

There's plenty of room in here for equipment installation. Remember,

it must have a payload for flight to keep the CG forward.

One servo pictured here is just for steering the nose gear. A

parallel servo handles the rudders.

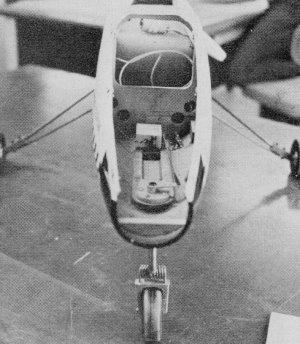

The pod hatch removed. That Sony TV camera, in its present location,

could handle weather sampling equipment, radar, a laser, etc.

Lighting all the plugs at once is easy with the springs seen

here. Engine runs both ways, so a pusher prop is not required. Note sump tank at

firewall.

This RPV is more than an interesting project designed for carrying movie

cameras. It is a multi-purpose research or practical application industrial tool

for carrying substantial payloads in a pusher configuration.

by Dave Scully

Sparrow is a special purpose, remote-controlled model being used by the Air Force

at Wright-Patterson Air Force Base to develop RPV (Remote Piloted Vehicle) technology.

This design represents the groundwork of a concept which may someday see the RPV

emerge as an operational weapons system performing missions which are presently

relegated to manned aircraft.

The advantages of such a concept are numerous. Aircraft no longer limited by

man's physical tolerances would be more maneuverable in air combat situations. Hazardous

missions such as low level recon, weapons delivery, and target marking could be

performed by expendable RPVs. Other advantages include a high degree of mobility,

lower development, production, and maintenance costs.

What role does the RPV play in civilian aviation? Remote-controlled models have

been used for some time as an aid in the development of full-scale aircraft, and

more recently as a means' of obtaining special aerial sequences for the film industry.

Universities and re-search agencies have utilized radio-controlled models for various

projects, among which the development of the Hill autopilot is probably the best

known.

Tomorrow's need for special purpose RPVs may exist in such areas as weather sampling,

high altitude research, and environmental control. We will undoubtedly see a growth

in engine development, control systems, and RPV design to meet these future requirements.

Sparrow is one design which could be adapted for use where requirements dictate

a model capable of carrying a substantial payload or a model suitable for aerial

photography.

Sparrow was designed by a team headed by Aeronautical Engineer Raymond Fredette

of the Flight Dynamics Laboratory at Wright-Patterson Air Force Base, Ohio. Mission

requirements for the full-size vehicle called for an aircraft which would carry

up to 100 lb. of payload and cruise in the range of 80 to 100 mph. Design considerations

included an unobstructed forward view for video experiments, and the capability

of accepting a variety of payload configurations. As a result, the design presented

evolved as the most desirable configuration for planned remote piloting experiments.

The model presented in this article is actually a half-size version of the Fredette

design, which was built as an engineering aid, and proved to be extremely useful

as a low-cost method of elevating performance, and developing fabrication techniques

relative to its full-scale counterpart. A Sony video system was later installed,

and basic piloting experiments via video were performed with excellent results.

Sparrow exceeded our expectations in its flight characteristics, and its suitability

as a test bed for future experiments. Apart from a lack of readily available engines

for models of this size, I can honestly say that we encountered no major problems,

either in constructing or in flying Sparrow. Our plane has flown well with a Ross

4 and even better with the Ross 6.

A model of this design as published, or possibly as an enlarged version, might

be useful to a modeler interested in performing experiments of his own, or in taking

in-flight movies. As I mentioned before, inexpensive available engines pose a problem

and possible alternatives might consist of using two engines (60s or 80s) mounted

on the booms as in the P-38. Little would be gained by shrinking the design, as

the wing loading would increase with a corresponding decrease in payload capability.

Generally speaking, the larger the model (wing area), the more efficient the design

will be in terms of its payload percentage.

Fig. 1 shows a comparison of the half-scale to the full-scale that may be helpful

to those who would want to determine their own requirements for an enlarged model.

| |

Figure 1 |

|

|

Half-Scale |

Full-Scale |

| Wingspan |

80" |

160" |

| Engine |

2 hp |

12 hp |

| Wing area |

7.5 sq. ft. |

30.0 sq. ft. |

| Wing loading |

3 lbs. sq. ft. |

7 lb. sq. ft. |

| Gross wt. |

25 lb. |

200+ lb. |

| Payload |

10 lb. |

100+ lb. |

If a five-lb. movie camera was the desired payload, two 60s on the half-scale

would probably be sufficient to achieve good takeoff and flight performance.

Construction

A very general description of the techniques used in fabricating this model are

all that will be described, as it is anticipated that the experienced builder will

adapt this design to his own proven methods of construction. Suggested changes for

a simplified method of building this model would be to use a balsa wood box construction

for the pod and the booms, and the more conventional method of control surface found

on most RC models. The flaps could be eliminated on the half-size version, as we

found we could land quite slowly without them. However, for larger models or flying

fields that require steep approaches and the slowest possible touchdown, by all

means include the flaps.

Pod - Fiberglass construction was utilized to gain maximum internal space to

accommodate payload requirements consistent with minimum cross sectional area. As

I mentioned, balsa wood construction could easily be substituted and past construction

articles on scale models of the OV-10A would be a good source of ideas, however

I leave this to the ingenuity of the readers. Fiberglass construction is not really

difficult; the following is a brief description of the steps we used in constructing

the fiberglass pod. Experiment with small parts such as wheel pants, cowls, etc.

before tackling a complete fuselage. Once you learn the process, it's hard to go

back to the glue and pin method of construction in terms of the savings in cost

and time.

The original pattern was carved from urethane foam (Pro Foam would be suitable

for this purpose) and sealed with K& B coating resin. The resin is sanded and

reapplied as necessary to obtain a smooth surface. The pattern was designed to split

along the thrust line and the two halves were mounted on plywood boards. The pattern

is then coated with a good paste wax and buffed thoroughly. A coat of vinyl separator

is applied by brush or spray and allowed to dry. The mold is constructed by brushing

on a gel coat (commercially available) to the prepared pattern and allowing it to

set up. The mold is then built up to the required thickness (1/8" is sufficient)

with layers of fiberglass mat saturated with polyester resin. The mold is allowed

to cure at least 48 hours before removing it from the pattern and is then washed

with water to remove the separator. The steps involved in making the finished pod

are the same as for the mold except that fiberglass cloth is used instead of mat.

The pod on Sparrow is laid up with one layer of seven-oz. cloth and a doubler of

two-oz. cloth. The rear of the pod is reinforced with seven-oz. cloth to handle

engine vibration. The excess cloth above the parting line of the mold can be trimmed

off with a sharp knife just after the resin sets up (about 30 min.). The pod halves

are left in the molds at least 24 hours and then removed, washed and held together

with masking tape. They are then joined with a one-in. strip of cloth applied to

the inside with polyester resin. Plywood formers are installed using a putty made

of polyester resin and silica powder as an adhesive. The forward hatch is cut out

last with a razor saw and a flange installed to accept hold-down screws.

Wing - The wing sections used are NACA 23012 at the root and NACA 4412 at the

tip. The leading edge radius has been reduced and the forward coordinates have been

modified to allow the wing to operate within a Reynolds Number range of .88 to 1.5.

Standard foam wing construction techniques are used with the following exceptions.

Access tunnels are cut through the cores using the guides pro-vided on the wing

templates. The wing is covered with 1/64th plywood using Bestine rubber cement as

an adhesive on foam-to-wood bonds and Formula 2 epoxy on wood-to-wood bonds.

If the wing templates are lined up on the datum line, you will notice that the

tip has effective wash out (e.q., the tip has negative incidence as compared to

the root section and insures that the tip will stall last). This factor contributes

to the outstanding slow flight characteristics of Sparrow and it is important to

insure that the wing is built accurately. We found it advantageous to cover the

wing in the same manner as a Formula I racer. Each wing panel was cut from a separate

foam block which was parted to form an upper and a lower mold; the wing core was

then placed in these forms while wrapping. Since the wing has no dihedral, the wing

panels were joined together using the lower foam blocks as an alignment guide. The

flaps are connected via a fiberglass arrow shaft pivoting on plywood bearings. The

flaps are glued to the shaft with epoxy and pinned with toothpicks. The ailerons

are connected using 90° bellcranks and 3/16" dowel pushrods running through the

access tunnels pro-vided in the wing. The extension harness for the boom servos

are also routed through these tunnels. The wing center section is reinforced with

fiberglass cloth and epoxy after joining.

Booms-The booms are fabricated from Styrofoam and covered with 1/64th plywood

with the exception of the section at the wing saddle, which is built up and sheeted

with 1/8" balsa plank. A 1/16" balsa spline is glued down the top center of the

boom and a 1/16" plywood plate is installed below the vertical stabilizer to add

rigidity and serve as a mounting plate for the elevator bellcrank. The 1/64th plywood

covering is dampened with a mixture of ammonia and water to prevent splitting while

wrapping and is bonded to the foam with rubber cement. The plywood is lapped on

top of the boom and the seam covered with a 1/2" strip of 1/64th plywood secured

with epoxy. The forward section of the boom is rein-forced with fiberglass cloth

and epoxy.

Tail Surfaces - The foam and balsa surfaces are constructed in much the same

manner as the wing. Note that the left vertical stabilizer requires an access tunnel

for the elevator linkage. The rudders are mechanically interconnected using a nylon

linkage housed In a strut made from K&S streamline tubing.

Tail boom at wing saddle shows location of elevator servo here,

rudder servo in other boom. This part of boom is balsa; rear part is fiberglass.

Bottom of wing shows receiver location, flap servo and aileron

servo.

Engine and Miscellaneous - Sparrow has been flown with both the Northfield Ross

4 cylinder and 6 cylinder engines. The Ross was chosen primarily to reduce vibration

effect on the video equipment and proved to be satisfactory, although a bit expensive

for the Sunday flier. The Ross was not designed to be flown as a pusher but since

it is a reed valve engine it can be operated in either direction. To date our Ross

engines have been operated in reverse rotation using 14/6 and 16/6 tractor props

respectively without suffering any ill effects.

Woodcraft Mfg. was the source of our props and I believe they can supply the

larger props in either the tractor or pusher configuration.

The fuel systems we use on our project aircraft are strictly homemade (Jim Cline

specials) and the normal procedure is to find a container that will fill the available

space. In this case we used a plastic aspirin bottle which was modified for fuel

lines by using grommets (similar to the Tatone stick-a-tube method) to seal the

tubing where they enter the tank. Sparrow's fuel system is not designed for prolonged

inverted flight and it proved satisfactory to run a feed line from the lower rear

of the tank and a vent line from the top of the tank to complete the system. With

the Ross engines it proved necessary to run a larger than normal feed line (about

1/4" I D) to the engine and cobb up a brass tubing manifold to feed the individual

carburetors.

The main landing gear strut was bent from 1/4" drill rod and re-tempered, however,

two pieces of 5/32" music wire bound together with brass wire and soldered would

do just as well. The tandem wheels (three-in. Du-Bro slicks) on the main gear have

worked well in the absence of larger commercially avail-able wheels.

Finishing - The model was completed using K&B products. All wood was sealed

with coating resin and the model primed and finished with SuperPoxy paint.

Checkout - Our ground checks prior to flying consisted of the following. CG located

between 21.5" and 24" aft of the nose. Control deflections: ailerons 150, rudder

300, elevator 250 up, 300 down, and flaps 00-450 range. The radio was given a thorough

range check both with the engine running and static. It was found that a capacitor

(Erie Red Cap PN 8101-050-651-10ZM) had to be added on the Pro Line receiver to

eliminate problems caused by the long leads to the boom servos. One cap was added

on each channel between the decoder output and ground and the receiver was then

retuned. We then went one step further and secured the aircraft to the top of a

station wagon and charged up and down the runway checking for flutter and the odd

chance that we could get a 4000-lb. payload off the ground. Finally, deciding that

there was nothing left to tighten, adjust, or paint, the batteries were charged

and we headed for the flight line.

Flying

Takeoffs with a gross weight in excess of 25 lb. (ten-lb. payload) requires a

long ground roll. With 100 of flaps lowered, the model accelerates approximately

150 ft. before the nose wheel is lifted off, about 15 feet later the plane is airborne

and climbs out quite rapidly. In flight, Sparrow is stable and relatively easy to

fly. I'm not going to "put you on" and say that the design will fly the entire FAI

pattern with a sick engine. In fact, with a three-lb. wing loading on a model of

this size it should fly like a nervous brick, but the point is, it doesn't. Sparrow's

flying and handling characteristics compare more closely to a light aircraft than

to a model, although forgiving in most circumstances, she won't tolerate rough handling

and is definitely a model for the experienced flier. The control response is positive

without being touchy and stalls are gentle and predictable. (You can almost feel

the controls get mushy.) With full flaps and down trim the plane can be slowed to

a crawl with no indications of a stall.

I can't give much of a comparison as to the flying qualities at different weights

since Sparrow has to carry payload or ballast to balance properly. The lightest

weight the model was flown at was 22.5 lb. on the first test flight.

The only aerobatics that have been performed to date have been rolls and one

short field landing. That is to say, I landed about 50 ft. short of a long field

when I found you can't stretch a glide with a dead engine. The airplane suffered

only minor damage but my pride suffered more by missing a 7000-ft. runway with a

seven-ft. model.

On landing, Sparrow's sink rate is somewhat higher than one is used to (as you

might have gathered), but touch-down is quite slow and, as I stated before, flaps

have not been found necessary as a landing aid on this size model.

I would be interested in hearing from groups or individuals who would benefit

from a special purpose model such as described in this article. Let me know the

payload requirements and purpose of its use. Sufficient interest in this area might

warrant production by a kit manufacturer of fiberglass and foam components that

would satisfy a variety of needs.

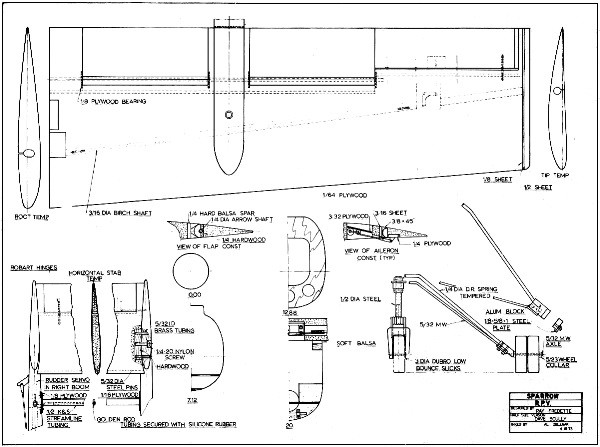

Sparrow RPV Plans, Plan Sheet #1

<click for larger version>

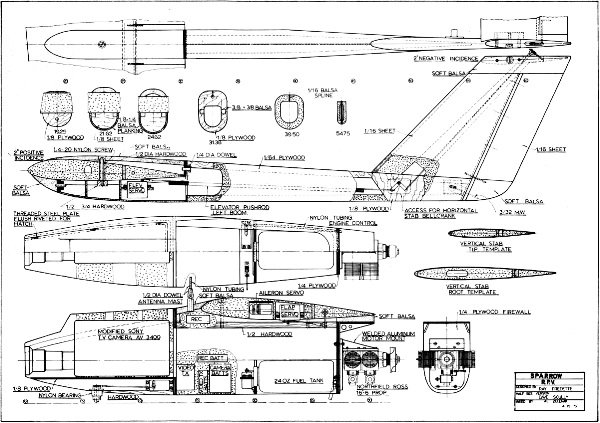

Sparrow RPV Plans, Plan Sheet #2

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted October 31, 2022

(updated from original post

on 4/25/2011

|