|

From what I can remember, this

October 1972 edition of American Aircraft Modeler magazine is the first

I received after joining the Academy of Model Aeronautics (AMA). I was thrilled

to be having a monthly modeling magazine delivered to my rural home because it was

rare that a copy of Flying Models or Model Airplane News would appear on the rack

in our local convenience store. Unlike today's age of instant and ubiquitous information,

getting ahold of desired reading material was not nearly as easy before the Internet.

Somehow, I managed to retain possession of that issue for nearly 40 years now. With

few exceptions, everything else from my childhood has vanished.

I remember being particularly interested in the Charybdis because it satisfied

the desire for a lot of different modeling interests - helicopters, airplanes, and

nitro-powered engines. In 1972 I was 14 years old and didn't have a lot of walking

around money - only what I scraped as profit from my paper delivery route and odd

lawn mowing jobs. So, I never actually built one, but I sure did pour over the plans

and article intently.

Having forgotten about the Charybdis until running across it again, I'm thinking

maybe a modern, electric-powered version would make for a great winter project.

Check back here in the spring to see if I make good on my idea.

Charybdis

With a twist of your wrist, this single-bladed, .010-powered thing swishes aloft.

Great fun and easy to make.By H.D.M. Sherrerd, Jr.

In Greek mythology, Charybdis was an extremely

powerful whirlpool off the Sicilian coast. This helicopter is not particularly powerful,

but like its namesake, everything revolves at a rather high rate of speed, and to

that degree at least the name was appropriately chosen by the inventor, Charles

W. McCutchen of Princeton, New Jersey. In Greek mythology, Charybdis was an extremely

powerful whirlpool off the Sicilian coast. This helicopter is not particularly powerful,

but like its namesake, everything revolves at a rather high rate of speed, and to

that degree at least the name was appropriately chosen by the inventor, Charles

W. McCutchen of Princeton, New Jersey.

Charybdis was developed 18 years ago, while McCutchen was living in Cambridge,

England, and caused something of a sensation when he took it to the British Nationals

of 1954. Since that time, variations on the "McCutchen Machine," as the design is

more generally called, have occasionally appeared in European magazines, but a prophet

is usually without honor in his own country, and the Charybdis seems to have been

completely ignored in the U.S.-a pity, since it is no tougher to build than a good

hand-launched glider, and more fun than tying firecrackers to your old flying scales.

Construction

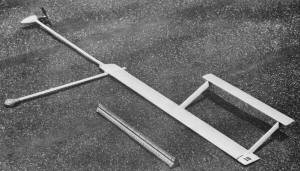

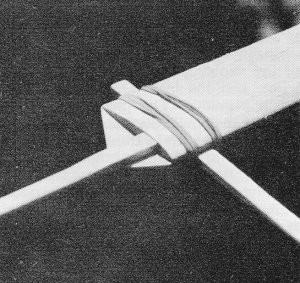

Construction is quite simple, with the emphasis on strength. The blade and stabilizer

are of sheet rather than built-up, the motor and balance arms are of spruce, and

the hub is reinforced with 1/16th plywood. The motor arm is inlaid into the lower

surface of the blade, the reinforcing plate double-glued over the joint, and the

whole bound with silk or other light cloth. This area is then virtually unbreakable,

and also a good flat surface for the balance arm to bear against. You can, of course,

glue or even bolt the balance arm in place, but Charybdis is much easier to carry

around if the arm is detachable.

The blade is simply a 2' x 2" lath of 1/4-in. medium sheet balsa, shaped to a

constant Clark Y section. No wash-in, no wash-out, no dihedral breaks; the squarest,

easiest wing you ever made. Use a template to maintain section accuracy. Don't try

something with undercamber instead. McCutchen tried both undercambered and curved-sheet

airfoils, and found the resulting Charybdis to be unimproved, at best, or just plain

unstable, at worst.

The stabilizer struts are 1/8th hard sheet sanded to a streamline section. Use

plenty of glue and perhaps even some silk reinforcing at the strut-to-stabilizer

joint, the only vulnerable area of Charybdis. The stabilizer itself is also 1/8th

hard sheet, but is given a lifting section. Be careful to set it at an angle of

at least -50 or -60 relative to the blade, as this is most important.

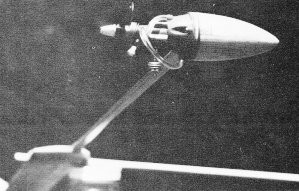

The motor pod is so designed mainly because it looks good. The streamlining probably

helps a bit, but is really unnecessary. On the other hand, it does provide a solid

mass behind the firewall (if you can call it that) and a little more weight. (The

Cox 010 is awfully light.) The 1/8-in. plywood firewall is inlaid into the motor

arm, and the pod itself built up from the same 1/4-in. stock used for the blade,

or anything else in the scrap box, then carved and sanded to shape With the motor

inverted, as shown in the photos, the mounting screws bear through into the spruce

arm instead of the soft balsa. Add a wire guard loop if you think it necessary,

but the prop generally seems to be enough protection for the glow plug even when

landing on bare spots.

This has got to be the easiest helicopter type thing yet-only

one rotor blade!

Rubber band mounted weight boom affords easy adjustment of CG

and crash protection.

Inverted Cox .010 works much better than if it were upright,

but no one knows why. Don't fly over concrete.

Thinned, clear, hot, fuel proof dope is used on everything except the motor pod

and adjacent portion of the motor arm, where straight dope is used for extra protection.

Colored dope could be used, of course, and should produce a pretty jazzy effect

with Charybdis revolving at the speed it does.

The inverted position of the Cox 010 has been found the best after much painful

trial and error. The tank outlet is slightly high, but the fuel line itself is at

the extreme outside of the swept circle, and fuel does not have to fight centrifugal

force on its way to the needle valve. The other arrangements that seem so obvious

either don't work for one reason or another, or offer no particular advantage.

Because of variations in engines, fuels, weather, altitude, etc., finding the

proper needle valve setting is something you must do yourself; there is nothing

else for it. But there is one peculiarity of the system worth mentioning that makes

all the difference in running time: an odd combination of forces and pressures is

at work that requires blocking off one of the filler nipples for maximum engine

duration. With both nipples open, engine run will be 15 to 20 seconds. With one

blocked off, the run will be well over a minute. This can be done with a short length

of pinched-off tubing, or a longer piece running to the pressure-tap nipple. With

this latter system you don't lose the short piece in the grass while fueling-it

stays attached to the pressure-tap. You can, of course, use a control-line tank

and find the optimum setup yourself. However, the shortest fuel line is always the

best, and use of the integral tank has the advantages of simplicity, strength, and

aerodynamic cleanliness.

Flying

Launching may seem a bit hairy at first, but is really no problem if the CG is

located approximately as shown. To avoid losing fuel from the inverted tank, turn

the Charybdis upside-down and start as usual. Now grasp the hub area with your fingertips

on the blade leading edge and thumb on trailing. Raise the whole affair over your

head while simultaneously turning it upright; snap your wrist to start rotation,

and push upwards. Then duck, and run into the wind, since you probably haven't got

the carburetion right to begin with. Try again, until the engine continues to run

and Charybdis climbs away like a startled mallard.

An alternate launch method is to gusset the general area of the CG, drill a small

hole at the approximate center of rotation, and impale the Charybdis on a headless

nail driven into the end of a stick. In this case Charybdis will simply fly itself

off once it picks up sufficient speed. McCutchen remarks that this is a good idea

while getting the carburetion and balance unscrambled, since it prevents powered

crashes while in an unstable condition.

Once properly trimmed, Charybdis is remarkably stable. The rate of climb can

be varied by adding or removing clay, and by sliding the balance arm in and out.

But this will not make as much difference as you might think, and unless carried

to extremes, will not seriously disturb autorotation characteristics following engine

shut-down. If the Charybdis is really out of balance, of course it won't take off

to begin with. Changing the stabilizer angle, on the other hand, will make a great

difference in rate of climb. An adjustable stabilizer, or at least a movable tab

on the' fixed one, would permit complete freedom of experimentation.

The other factor that most strongly affects performance is power. With the 3

x 1.25 standard .010 prop, time from launch to touchdown averages around a minute

and 30 to 45 seconds. Charybdis climbs steadily for several hundred feet, depending

on engine run, then descends in autorotation for anything from 30 seconds to a minute.

On one memorable flight of this sort, the Charybdis got hung up in a thermal at

100 feet or so and just sat there, silently autorotating over one spot for something

close to two minutes. Total time was 3:15 for a rather different max flight.

But to really have a ball with Charybdis, try this: Turn the prop around to reduce

thrust, or use a 4-1/2 x 2, .020 prop, pile more clay on the balance arm, maybe

try a masking tape trim tab on the elevator-anything to hold it down. It will take

a while to work out, but you can get the Charybdis to hover waist-high. It will

first sink to a grass-cutting level, then find an equilibrium altitude in ground

effect at two or three feet, and just sit there, drifting with the breeze, following

the contour of the ground. McCutchen rigged one to do this so well that it would

go down the gentle bank of a stream, cross over, then climb the opposite bank and

continue wandering off across the fields. He says it was quite upsetting to casual

observers along the flight path.

While hovering like this, Charybdis will produce the weirdest sound you have

ever heard outside a science-fiction movie. You'll think the Martians are coming-it

is a kind of whoop-whoop-whoop-whoop gradually increasing in pitch and frequency,

with an underlying humming note, and the scream of the engine. All this may be only

a peculiarity of the author's Charybdis, and may not be true for others-even working

from the same plans, everyone builds slightly differently. But for the Charybdis

in the photos it's real. And strange.

AAR Note: The Charybdis' principle of flight is very similar to that of the familiar

maple tree seed. Here is

NASA's

page on them.

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted October 31, 2010

|