|

Here

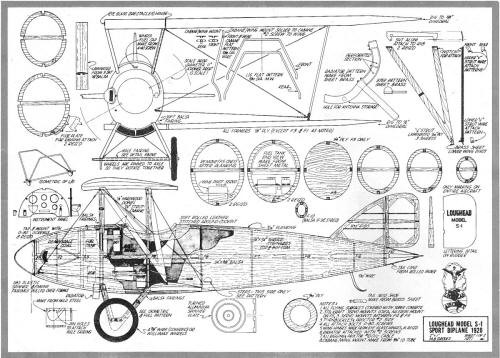

are article and plans for the Loughead Sport Biplane Model S-1 Plans,

that I electronically scanned from page 42 of my purchased copy

of the October 1972 edition of AAM. You might be able to scale up

the image below if suitable plans cannot be located. Plans for this

fine model were drawn by Mr. M. B. Groves. All copyrights (if any)

are hereby acknowledged. Click here for the accompanying

historical article on the

Loughead S-1. "In 1919, Loughead [later renamed Lockheed]

Aircraft entered the small aircraft market with the revolutionary

single-seat S-1 Sport Biplane. Intended to be "the poor man's airplane",

it featured an innovative molded plywood monocoque fuselage for

which the Lougheads, Northrop and Tony Stadlman received a patent.

Its foldable wings allowed the plane to be stored in a garage, and

the lower wings could be rotated to act as ailerons and airbrakes.

Because no suitable engines were available, the company designed

and built its own 25-horsepower water-cooled engine for the S-1.

The S-1 was tested successfully at Redwood City, CA in 1919

by Gilbert Budwig and flew well. After the S-1 completed its test

flights, the pilot said it was the most flyable plane he had ever

flown. The plane went on to make hundreds of flights and proved

to be a very successful design. At an aircraft show in San

Francisco, thousands admired the little S-1 aircraft, but not a

single person ordered the $2,500 plane. Only then did Allan Loughead

realize that the government's sale of war surplus aircraft for as

little as $300 had killed the market for new aircraft. As a result,

Loughead Aircraft closed its doors in 1920 and its assets were liquidated

in 1921. -

Wikipedia"

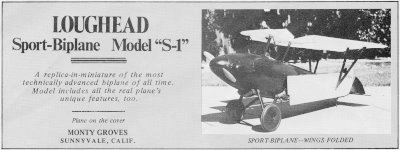

Loughead

Sport-Biplane Model "S-1" Loughead

Sport-Biplane Model "S-1"

A replica-in-miniature of the most technically advanced biplane

of all time.Model includes all the real plane's unique features,

too. Plane on the cover. by Monte Groves, Sunnyvale,

Calif.

Loughead S1 - Finished side view

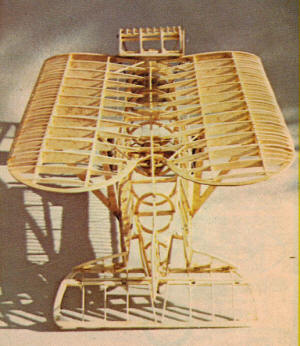

Loughead S1 - Open framework

Loughead S1 - Open framework, wings folded

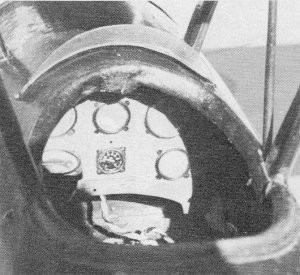

Loughead S1 - That's all the instrumentation the real plane

had, too, but arrangement of dials is only a guess.

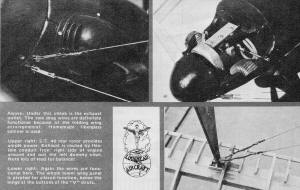

Loughead S1 - Scale detail

Loughead S1 - The one-and-only Loughead S-1 engine and the one-and-only

Tony Stadlman meet again in San Francisco. As Loughead's factory

superintendent, Tony's support in this research project has

exceeded all bounds.

One can become addicted to early aviation research. After researching

and building a model of Wiley Post's beautiful Winnie Mae (August

1970 AAM), we became interested in the aircraft im-mediately preceding

the Lockheed Vega. Precursor to the Vega was the Loughead Sport-1

biplane, and research into this little-known one-of-a-kind air-craft

has been an engrossing and fas-cinating project. Though built

and flown 52 years ago, with the exception of Allan and Malcolm

Lockheed, most of the original participants are still with us. And

with-out their cooperation, the S-1 project would never have gotten

off the ground. During the Vega research we came across

six photos of the slender little bipe. With these and five or so

others we located in the Lockheed-Burbank files, we began the project.

After two years of constant correspondence and probing into various

personal and public ar-chives, some 55 construction and flying photos

have been amassed. The original 1920 Loughead sales brochure, as

modi-fied, provided all the dimensions. Interviews and correspondence

with Jack Northrop, the principal engineer, Tony Stadlman, the shop

superintendent who built it, Gil Budwig, the original test pilot,

and several others provided an almost complete story. One

of the more exciting side effects of historical aviation research

came the day my wife and I drove home with the original, one-and-only,

two-cylinder engine, its propeller and spinnerring. The S-1 engine,

which had dropped out of sight for over 30 years, is slated to go

to the Smithsonian as soon as it's overhauled and test run, providing

I can locate a Master Carburetor. Since no original drawings

have been found, the drawings with this article were generated over

a long period of time, and are based on the photos, published dimensions

and review by the men who created and flew the S-1. Data and photos

are still being located, so the search will continue. The

Loughead S-1 had several unique design features-an elliptical molded,

monocoque fuselage, and for lateral control the entire lower wing

pivoted at the root. After landing and during the landing roll,

the pilot could disengage the lower wing and pivot the entire lower

wing 90° to assist it in braking to a stop. The wings folded up

so that the plane could be towed down the highway and stored at

home. The configuration of the model of the Loughead S-1

is scale, and based on the 1:1's appearance at the 1920 San Francisco

Aero Show. Like the original, the model is complete with folding

wings. Since most of the flying of the real aircraft was done without

the cheek cowls, these can be eliminated and you'll still be "scale."

While the model has folding wings, they can be eliminated

too, if you're concerned about the structural integrity of what

appears to be (but isn't) a Mickey Mouse arrangement. The folding

wings were built into the model to confirm the functional operation

that the original designers intended and to further confirm that

the dimensions and proportions were correct. Except for the

lateral control surfaces, which may seem strange but really are

practical, the aircraft is conventional in configuration.

Construction Wings: Wing construction

is conventional with the exception of the trailing edges. To obtain

the scalloped effect, use 1/32" wire, much the same technique as

on the original. Small brass tabs are spaced two in. apart and soldered

to the wire edge prior to attaching it to the ribs. This, coupled

with the use of one-piece Super Coverite covering for each panel,

provides the proper amount of shrinkage for the scale, scalloped

effect. The lower wing is built up using a spruce box spar

which will carry the required loads when it's used for lateral control.

The number of ribs and their spacing is scale with respect to the

original. However, the airfoil still isn't exactly known, so the

model airfoil is approximated from the photos we've collected.

The "V" struts, the cabane strut construction, and their

installation are shown on the plans, and are easy to follow. The

small fittings on top of the cabanes for wing and wire attachment

are made from tubing and soldered to the cabane wire mounts before

the wood fairings are attached. The plans depict a different

leading edge than that shown in the construction photos. The more

solid leading edge shown on the plans will tend to keep the wings

from warping. To cover the wings, cut one piece of Super

Coverite to cover both top and bottom of the wing. Start at the

leading edge and cover the bottom to the trailing edge; follow Coverite's

instructions. With the bottom section now covered, continue up and

over the top so that you end up back at the leading edge. Super

Coverite provides additional strength to the wing, and the shrinkage

can be controlled without getting out of hand. Fuselage

and Empennage: As with the Lockheed Vega model, we chickened

out in making a scale concrete mold for the molded fuselage halves.

The model is planked over a preformed skeleton frame. Unlike

the Vega, which was made up of two identical symmetrical shells,

the Loughead S-1 required two asymmetrical shells. (On the S-1,

there's greater depth below the centerline.) Construct a

crutch, and attach the top and the bottom formers and stringers.

This helps reduce the likelihood that you'll run into a fuselage

warping problem, which is, as we all know, a giant pain in the neck.

All formers, except for F-1, the firewall, F-3. and the end former

F-1D, were made from 1/8" ply. F-4 and F-5 are to be doubled later,

as shown, and provide suitable landing gear and cabane mounting.

Form the front and rear landing gear struts from 5/32"

wire from the flat pattern as shown. After confirming alignment,

solder the struts to the mild steel fittings as shown in the isometric.

After the landing gear assembly is completed, install it and epoxy

it well in between F-4 and F-5. (Double up F-4 and F-5 as shown.)

Be sure of your alignment because it's difficult to get to afterwards.

The S-1 had an axle, which, when used properly, helped

prevent ground handling problems. Pin the wheels to the axle so

that they'll turn together as a unit, not independently.

The

conventional, early Loughead tail skid is made from 5/32" wire with

a soldered brass shoe. Attach this to the lower stringer, blocked,

as shown. Remember to keep the entire structure lightweight toward

the rear. The end former, F-1D, is made from 1/4"

balsa and is left solid until after planking is complete. When you've

finished planking, cut out as required to give enough clearance

for the empennage controls. The cabane struts are

installed between the doubled F-4 and F-5, and epoxied well into

place. Because of cramped working space, solder up

a fuel tank that mounts per-manently behind the firewall, then snake

the venting fuel feed lines through the firewall. The filler tube

is installed up through the top of the fuselage, and is threaded

to match a 4-40 screw which was modified with a butterfly head.

(On the real S-1, this screw cap covered the water tank to the water-cooled

engine.) Be sure to completely check your home-made tank for leaks

before installation. Because of limited space I selected

a rear rotor, Supertigre 40, with a Perry carb to improve idling.

Mount this to a wooden rail mount of your own design. Attach the

rail mount to the firewall with No. 6 blind nuts with Allen head

screws. The ST 40 is mounted flat with the cylinder out

the right side for cooling. This places the exhaust downward. A

friend of mine, who has access to such things, provided some flexible

beryllium copper wave guide material for the exhaust stack. This

was attached to the engine exhaust, folded under the engine, and

directed out to the left side (opposite the cylinder). Thus, the

now somewhat muffled ST 40 is a deep-throated powerhouse. (If you

don't have access to wave guide, silver solder up something similar.)

The lateral control provided a unique challenge to implement,

and while it eventually worked like a charm, it gave us all sorts

of headaches until Jim Sunday, famous local "test pilot" and bosom

chum, came up with the clever concept shown on the plans.

The wing pivot block, which provides the lower wing support

and pivot drive, is a ply structure with the pivoting assembly supported

in a Teflon block. There's no way that this can bind. The pivot

block is installed and blocked in as shown just aft of F-5. Check

for alignment and centering. The total movement of the lower wing

is only ±60°. It must be positive with little or no slop.

The lower wing is attached to this pivot point by scrounging

some eyeglass hinges from your local optometrist. The lower wing

is held on with the screw that holds the hinges together. Carefully

solder each side of the hinge - one side to the plate which you've

epoxied and screwed to the wing, the other side to the pivot shaft

in the block. Provide two additional balsa formers up front

around the engine compartment: one in front of the firewall, F-3,

and one behind the front ring, F-1. Force them into place between

the crutch and glue to the top stringer, but do not glue to the

crutch or F-1 or F-3. You're almost ready to plank. But

first install your servo trays, and check out your servo action

on the lower ring pivot and throttle. I used standard servo mounting

trays mounted to hardwood rails between the formers. Now,

plank! For ease of assembly, the 3/16" planking strips should be

cut to 3/8" widths. After planking and preliminary shaping and sanding,

finish the fairing around the lower ring pivot block with soft balsa

blocks. Now's also the time to fair in the landing gear and cabane

struts. (Check for fuselage warping as you glue, pin and plank.)

Attach and glue the Super Coverited horizontal stab to the

fuselage. This should be done with the elevator attached to insure

proper operations. Now glue the vertical fin directly to the fuselage

after squaring it with the stabilizer. Cut out F-10 and connect

the rudder and elevator controls. Layout and cut the planking

for the cockpit. This requires cutting through the top stringer

and the doubled F-5. Use your razor saw to cut F-5 vertically.

After some additional sanding and filling, cover the entire

fuselage with Super Coverite, using longitudinal strips overlapped.

This adds unbelievable strength and cuts finishing time by more

than half. Up front, cut out the cowling using a razor saw

to cut vertically between the formers F-1 and F-3 and the extra

unglued balsa formers. Now cut horizontally along the top of the

crutch between F-1 and F-3. And out pops a cowling! Cut

out the cylinder and exhaust areas, and install the engine and exhaust.

Fittings, etc.: The S-1 had a non-standard Albatros,

Halberstadt, rounded-type, Snyder-type spinner. To achieve this

miserable shape, heat 1/8" ABS sheet plastic, and pull over a turned

form. The ABS plastic spinner is mounted to the aluminum spinner

plate with 0-80 screws. Cut out notches on either side of the plastic

spinner for the 11" wooden prop. Cheek cowls, if used, can

be made in a similar manner to that of the spinner. Just remember,

you've got a double compound curve over which it must fit.

The removable instrument panel is made from ply. Using double

sticky foam tape, mount your battery pack to the back of the panel.

Sprinkle the panel lightly with the basic instruments: airspeed,

throttle (right side), oil pressure, water temperature, altimeter

and compass. Other than the type of instru-ments used and the location

of the throttle, the exact panel layout is not known at this time.

The bottom of the pilot's seat is made from balsa and the

back is made from shaped cardboard. The whole thing is covered with

an old, thin piece of scrap leather. The tail cone is a

piece of bond paper that's been rolled and glued with a balsa plug.

Attach the tail cone to the fuse with pins. The windshield

frame is brass. A single piece of butyrate plastic windscreen is

set in the frame and attached to the fuselage. A soft, old,

bought-in-Hong Kong leather wallet was used for the padding around

the cockpit. Contact cement will attach it around the cockpit. Then

stitch it through the planking and Coverite to hold it securely

and, at the same time, give it an authentic appearance.

The original S-1 had wire wheels with fabric wheel covers. Use four

circu-lar disc pieces of old sticky Coverite. (Cut a 1/4" axle hole.)

Very carefully remove the tire, place the Coverite over the wheel,

and press the Coverite discs up and over the edge of the flange,

one for each side. Carefully replace the rubber tire. This will

hold the cloth discs in place while they're being painted. The wire

spokes tend to press through the cloth covering which provides that

little extra touch of realism. Using the pattern provided

on the plans, solder up the underslung radiator from a piece of

sheet brass. Attach it to the fuselage with 0-80 screws. Incidentally,

use the inside of the radiator to stow your antenna when you're

not flying. Rigging: Proctor turnbuckles are used

in the rigging, one on each wire. When rigging, be sure there's

zero incidence in the wing with respect to the stab. Allow no twists

in the wing, and, by all means, safety wire those turn-buckles.

(I test ran the engine once without safety wires, and thirty minutes

later I was still looking for pieces and parts.) Paint and

Color Scheme: The S-1 had about as simple a color scheme as you

can imagine. Wings, elevator and rudder are cream. The fuselage,

wheel discs, spinner and horizontal stabilizers are maroon. Both

the cockpit leather and the lettering on the rudder are black. And

paint that radiator Brewster Green-or you'll get a thorough Czechoslovakian

tongue-lashing from Tony Stadlman. (Stinson Green, as packaged by

Pactra, will do nicely.) Use butyrate dope for the cream

surfaces and Hobbypoxy for the maroon. You'll have to mix all colors.

As for cream, it is cream, Insignia White plus a little yellow.

As for the maroon, this nondescript color just about brought our

happy marriage to an end. Mix maroon, call it Maroon, and stick

to it! The color that best matches is the same as fresh beef liver.

How about that reference? Wing Folding and All That Jolly

Fun: Now if wing folding is your bag, then have at it. But

after this experience, it's no longer mine. Disconnect the two drag

wires at the nose on each side. Remove the two forward screws on

the upper wing. Fold up the center section and the triangular folding

sections on the stab. Reach inside and slip off the two vertical

pivot drives. Then fold the lower wing 900, trailing edge up. Now

each wing assembly can pivot toward the rear. (And when I think

of all the sweat, well, never again.) Center of Gravity:

With respect to CG, after much debate we decided to ignore the small

lower wing and place the CG as shown. When I'm building,

I have a tendency to get a little tail heavy (as well as on the

model), so I had to add a remov-able lead horseshoe around the engine.

If you have to add such a mass, be sure that it's well secured.

Flying With an 11" power prop and

the ST 40, we took it to the field and fired it up. Cameras at the

ready; fingers, etc., crossed, we watched Jim Sunday start his take-off

roll. Man, straight as a die. Up and out. Jim was a little

concerned about using the lower wings for lateral control, so he

didn't plan to try them until he'd gotten up a little higher. But

just after it broke ground, it started a very slight roll to the

left. Jim hesitantly and cautiously applied the correction. It worked!

Then, up and around the pattern. For the benefit of all

the highly-skilled photogs, he made several circuits. High-speed

passes. Low-speed passes. Around and around and around until my

suggestions to "bring it in, Jim" were bor-derline violent.

"Ya know," he laughed as he made one more circuit, "a guy could

get addicted to this little wing-pivoting toad." Then lining

up for the approach, he throttled back and the engine quit cold.

(This, due to a minor pre-flight adjustment.) On in she came, then

touched down just like it was supposed to. Those pinned-together

wheels are the only way to go. After congratulations all

around, it was discovered that the only problem was none of the

ground cameras were working. So, confident with our S-1, Jim did

it all again, and when I became certain he was determined to run

out of gas, I had to threaten him to bring her down.

Epilog Shortly after the second flight,

we discovered a leak in the fuel system and my receiver was soggy.

I got my radio out of there in a hurry, and we hung up the S-1 in

a place of honor in Jim Sunday's hobby shop. One evening, a

few weeks later and just before Christmas, Jim was open late. Along

with the fact that it hadn't been exactly a banner-type day, Jim

was alone in the shop and hadn't had his: dinner. He was feeling

less than jaunty-jolly when a young guy strolled into the shop and

started the normal I-just-came-in-here-to-kill-time casual gazing

around looking at all the "toy" airplanes hanging from the ceiling.

Jim folded his arms, leaned up against the wall and watched

the guy through heavy-lidded eyes. The young man looked at the S-1,

and then after making a few rather cool remarks about it, he said,

"Is that thing supposed to be scale?" The eyelids crank

up. "You bet it's scale. That airplane is exact. And anyway, who're

you?" "Oh, I'm sorry. I didn't introduce myself. I'm Allan

Lockheed, Jr." Not only do poor beleaguered hobby shop owners

have to put up with so-called scale experts all the time, occasionally

they have to endure practical-joking friends, ex-friends, and, oooh,

it was beauty-full.

Loughead S1 - Plan sheet 1

<click for larger

version>

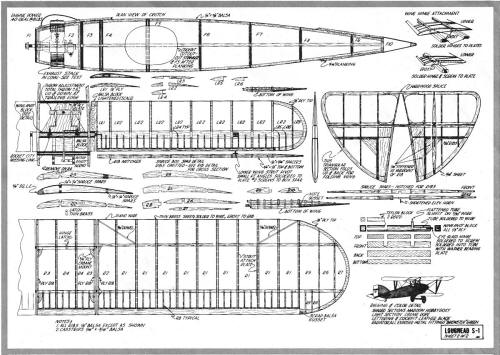

Loughead S1 - Plan sheet 2

<click for larger

version>

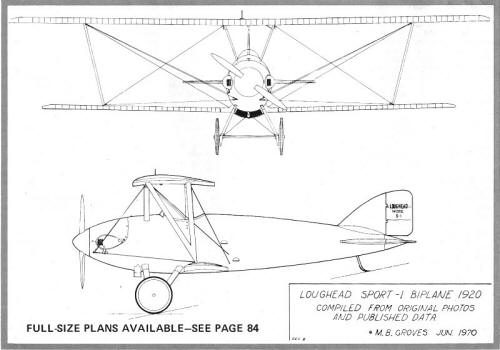

Loughead S1 - 3-view side and front

<click for larger

version>

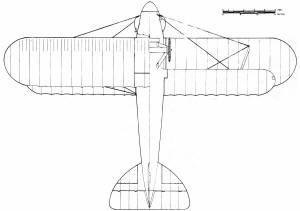

Loughead S1 - 3-view top

<click for larger

version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted November 6, 2010

|