|

The

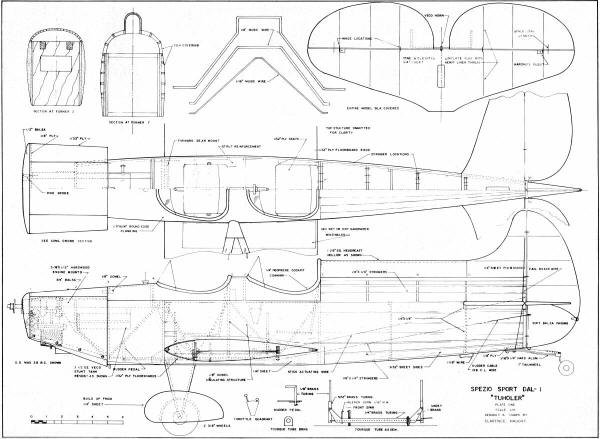

September 1973 edition of American Aircraft Modeler featured a combination

C/L and R/C, 1/6-scale model of the Spezio Sport DAL-1 Tuholer homebuilt

airplane. A 3-line systems is used for C/L so that throttle can

be controlled. Both versions call for hinged, movable ailerons and

rudder, with those surface being staked to a fixed position for

C/L flying.

Spezio Sport Tuholer

Homebuilts always make great Scale subjects. This one is a Control

Line Scale model with good stunting ability for those extra points.

It is also perfect for RC Stand-Off Scale. by Clarence Haught

The selection of a Scale subject for today's competition

is one of the most difficult tasks facing the Scale modeler. Gone

are the days when all that was required was a close resemblance

to a set of questionable three-view drawings, a non-scale glossy

finish, and lots of bent pins and thumbtacks in the cockpit. Often

the meet was won by the only ship able to struggle into the air

and complete a lap or two without the Scale crash bit. To

win in Scale today one needs a model that appears to be a real aircraft

magically shrunken to model proportions. This must be backed by

complete documentation in the form of accurate and detailed drawings,

photographs and specifications.

The Tuholer was chosen as a scale subject for its good

moments and ample wing/tail/ rudder areas.

That's a real good-looking pose. Would you believe a 35 is adequate

power even for stunting? By all means use the throttle for scale

points, realistic takeoff and touch-and-go.

How about that nifty scale tail wheel? It's worth several scale

paints. Cockpit is simple-it needs the full pilot and instruments

treatment if you can avoid weight buildup.

Symmetrical stunt airfoil is evident in this view of the model.

What it costs in lost scale points is easily made up by optional

maneuvers. Ailerons and rudder are fixed for flight unless you

fly it RC.

By visiting the larger meets and reading model magazines it becomes

apparent that a new trend is developing: the scale homebuilt. There

are many good reasons for this. Any aircraft built in the home workshop,

for example, can be duplicated part by part by the modeler if he

so desires. There are usually no elaborate fittings or forgings

to duplicate and similar materials are used in constructing the

model. Another advantage is that authentic scale documentation is

usually available from the original designer! Also on the plus side

are the variations seen on given homebuilt designs such as cowlings,

wheel pants, etc. Be careful on this one, however-you must be able

to document your version. If the variation desired is difficult

to document, then you are better off building a scale model of the

prototype. You may, however, exercise some freedom in paint schemes

and numbers as long as the original design is utilized.

Before selecting the Tuholer as a subject, I researched eight airplanes

in this general category. I settled on the Tuholer for a number

of reasons. My first interest in Control Line flying is stunt and

I wanted a subject with aerobatic capabilities. The Tuholer has

ideal moments and nearly 500 sq. in. of wing area. With an adequate

engine this plane will not be aerobatically disappointing. In fact,

the ship flies like a typical non-flapped stunter, and is smooth

and responsive. I made two scale deviations on the original:

a symmetrical airfoil and an enlarged horizontal stabilizer. The

plan shows the scale stabilizer length, but if you are not interested

in aerobatics, the ship will handle well with the smaller tail surface.

Deviations from scale must be listed in your documentation and will

cost you a few points; they are minor compared to the aerobatic

flight points possible with the slight modifications. While

we're on the subject of scale documentation, the winter 1971 issue

of Air Trails Sport Aircraft is a good source and the October 1966

issue of Sport Aviation, the official publication of the

Experimental Aircraft Association, has a lengthy article on the

Tuholer. Both issues are available and have three-views with dimensions

as well as an excellent cutaway view giving many usable details.

Plans including many photographs are available from designer Tony

Spezio for construction of the real airplane. There are

several features any scale model in this category should include.

In general, adhere to scale rib and stringer locations as well as

proper control hinge locations. Fabric areas should be silk-covered

and finished with enough dope to fill sufficiently, but the fabric

weave should be visible. Sheet metal covered areas should be well

filled with the proper "edges" apparent. Any sheeted areas, such

as leading edges, should be duplicated and trailing edges made as

unobtrusive as possible. The cockpit should have moveable rudder

pedals and sticks that follow control movements. Scale structure

should be visible in cockpit area; instruments, switches and secondary

controls should be properly located and duplicated. Give careful

attention to tail-wheels as many points can be added here. Throttle

control on the engine is well worth the effort, however the added

drag of the third wire will make aerobatics risky unless an engine

in the 40-45 class is used. You will have to be the judge.

Construction The Tuholer is not a beginner's

project so this will not be a glue-stick-A-to-former-B article.

My comments on construction are limited to specific details which

may be of help. The fuselage should be started first and

is simply sheet sides attached to the plywood former and engine

mount assembly. Stringers and sheet fillers complete the sides.

Formers in the after fuselage are built up from 1/8 x 1/4" strip

stock and the sides are joined at the tail post. The fuselage construction

should stop at this stage to allow easy assembly of wings, tail

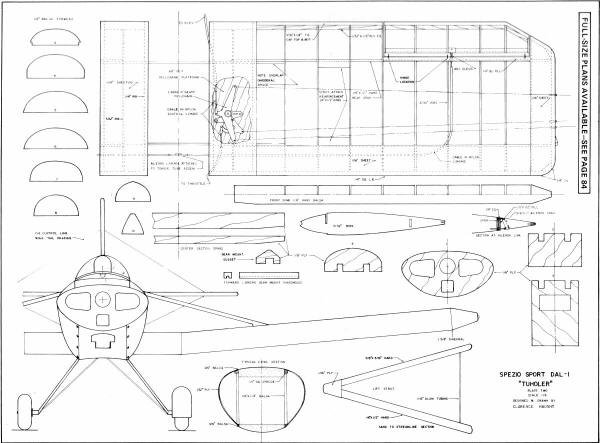

surfaces and landing gear. The wing is built next. The inboard

center section rib spacing is dependent upon actual fuselage width

so this dimension may need to be altered on your plans. The wing

is completely assembled without left upper center section planking

(over bellcrank) and installed as a unit into fuselage. Simply notch

fuselage from the bottom for spars and slip wing upward into fuselage

against the 1/4" sheet filler. Add lower filler sheet and wing installation

is complete. Two suggestions are in order here:

Drill the front spar for landing gear J bolts and notch front spar

to accommodate torque tube prior to assembly; reinforce bellcrank

mount with scrap balsa gussets wherever possible, as this is a highly

stressed area. You may wish to notch the plywood center section

spars for the bell crank mount. The tail surfaces are

made of 1/4" sheet with nylon thread used to simulate ribs. Silk

covering applied over the balsa and simulated ribs will provide

a scale appearance without the delicacy of a built-up surface. You

will note an extra elevator horn on top of the stabilizer as well

as the regular horn below. The upper horn provides correct stick

movement in the cockpit in relation to elevator movement. The bellcrank

is attached to the lower horn by means of a flexible cable in a

nylon tube. Anchor the nylon tube in several places. If threaded

clevises are used for connections, solder them in place after final

adjustment to prevent working due to vibration.

All

cockpit detail and controls should be added at this time. The "backside"

of fabric covering in the cockpit area can be simulated with Silkspan

doped to the balsa sides. 1/32 x 1/16" balsa laid flat will simulate

stringers. Structural tubing is l/S" dowel finished with zinc chromate

Aerogloss. Rudder pedals are soldered up from l/S" brass tubing

and hinged to the 1/32" plywood floorboard. Front and rear pedals

are linked with piano wire to a 1/16 x 1/4 x 3" dural strip pivoted

beneath the floorboard at the rear. At final assembly, 018 control

line cable completes the hookup to the rudder horns. The

torque tube assembly is also made from brass tubing soldered together

and attached to the floorboard before installation as a unit into

the fuselage. Coordinate this assembly step with the landing gear

assembly. Cockpit seats are 1/32" plywood. Don't forget

seat belts. Make the buckles out of sheet aluminum and the webbing

out 1/2" braid from the sewing shop. Commercially available

instruments may be used. I used World Engines instruments in the

rear cockpit only. However, if you purchase instruments, you must

list them in the documentation under "parts not constructed by builder"

and this will cost you points. They can be made using photographic

reproductions of the faces with frames fashioned from bits of metal.

Fuselage construction resumes after all controls and cockpit

details are complete. There are no stringers on the bottom. The

area around the cockpits is metal on the real ship and is made up

of 1/4 x 1/8" round edge planking and finished to simulate a metal

surface. If you mask around the edge of sheet metal areas prior

to building up the finish with filler, you will obtain a slightly

raised edge, which can be carefully beveled to simulate a metal-to-fabric

joint. This should also be done where the side stringers meet the

1/4" sheet filler in the area of the wing leading edge. Cockpit

coaming is 1/4" neoprene tubing with a quarter of its cross section

cut away to allow a good fit to the cockpit edges. Attach with epoxy

glue. Wing struts should be made up and fitted to the model

utilizing round toothpick alignment dowels. They should be finished

separately from the model along with the cowling and attached with

epoxy after the finishing process. The cowling on this ship

attracts more attention then anything else, but it was actually

quite easy to construct. Attach top and bottom balsa blocks to former

No.1. Two 1/8 x 1/4" vertical members hold them in alignment temporarily

as shown in the typical cowling cross section. Slip the cowl in

place and shape the top and bottom blocks. Next add 1/4" sq. spruce

to both edges of the balsa blocks. Allow clearance for the 1/32"

plywood side pieces at the top. Glue plywood side pieces to top

block with epoxy. Wet plywood and pull around former No.1 and down

to bottom block. Secure with masking tape and allow to dry at least

24 hrs. The tape is then removed and the formed plywood cowl sides

are glued in place; four No.3 1/4" metal screws are added to simulate

Dzuz fasteners and help secure cowl sides. A front block and a scoop

are added to complete the cowl. Attach cowling with bike

spokes and one alignment dowel as shown. No cutouts were made for

exhaust or needle valve on the original. The inside of the cowl

was coated with epoxy glue for a sealer. The cowl is removed and

the engine is started and adjusted prior to going to the flight

line. The cowling is replaced prior to flight and the engine is

restarted while you hold the model inverted in stunt fashion. The

exhaust will echo inside the cowl and provides a realistic sound.

There is plenty of air circulation to carry .away the exhaust and

to cool the engine. Some attention should be given the tail-wheel

assembly. Look at some full scale tail-wheel assemblies and try

to du-plicate them. A simple wire sticking out with a wheel attached

will detract greatly from the scale appearance. I used 1/16 x 1/4"

aluminum for "springs" and small copper wire with solder flowed

around it for "clamps." The swivel bearing was adapted from an RC

nylon tail-wheel bracket. Take your time on the finish.

Silk seems to handle best if it is drawn down over a previously

doped and sanded structure and adhered with a brush dipped in thinner

to activate the dope underneath. After water shrinking,

apply enough dope to seal the fabric but not so much that the fabric

effect is lost. Here again it will pay to look at some real aircraft

finishes and try to simulate them. Very few have hand-rubbed glossy

finishes on fabric. However, some homebuilts will, so you may want

to weigh this decision. Flying Be

sure of the center of gravity location. It should be two in. behind

the wing leading edge with the fuel tank full. If the CG is too

far forward, you have takeoff problems on rough fields as the tail

comes right up on takeoff. Since this ship has moveable

ailerons and rudder, they will have to be locked before flight.

I tie the rudder over hard right with rubber bands between the fuselage

lift handle and the rudder horn. Be sure this doesn't bind the elevators.

For initial flights you may wish to set the ailerons to assist in

maintaining the line tension (I use hat pins for this).

You will find the ship easy to fly and, if you have throttle control,

beautiful touch-and-goes are possible. Just set the model up nose

high with a little power and gradually reduce throttle as she settles

in. Prior to flying aerobatics with your Tuholer you will

want to cover your bets by careful preflight checks. First of all,

the flying surfaces must be in perfect alignment with no warps present

in the wing. A warp that will aid in maintaining line tension in

normal flight will work against you in inverted flight, possibly

causing you to lose the airplane due to slack lines. If

your ship weighs over 55 oz., you are getting near the maximum for

stuntability especially with a three-line control setup. The added

drag of that third line really shows up in aerobatics. Use the minimum

wire diameter allowed by the rules and 55 ft. length. A

good strong 40 is necessary for aerobatics. Set it up with about

1½° of offset to the right to insure good line tension. The ailerons

will, of course, have to be secured in the neutral position. I use

a 11 x 5 prop but the ship does fine on a 10 x 6. The longer prop

looks better with such a wide cowling and is nearer scale diameter.

Stunting a scale ship may seem sacrilegious but, if the

model has the capability, why not garner those extra points offered

in the rulebook? These maneuvers consist of loops, wingovers, figure

eights and inverted flight. If you're not an experienced stunt flier,

do the maneuvers you can and let the rest go. I am hesitant in recommending

the vertical wingover, however. This is an extremely simple maneuver,

but I feel it places the model in undue jeopardy. Engine failure

or even hesitation is more critical in this maneuver than the others

because line tension is marginal at best and, if the wind is blowing,

it tends to be worse. Loops and eights are done directly downwind

with line tension aided by the wind. I nverted flight should be

entered downwind with subsequent recovery downwind also. Generally

speaking, inverted flight is safe in moderate wind which shows little

or no effect in normal flight. Figure-eights in scale should

be the type known as lazy eights and not the type shown in the aerobatic

rules. In fact, this maneuver is one of the best training maneuvers

for the beginning stunt flier as it gradually leads him into inverted

flight and overcomes his fear of giving "down" control at the handle.

The maneuver is entered from a shallow dive adding up elevator

until two-thirds of a normal loop is completed. The elevator is

momentarily neutralized resulting in a shallow inverted dive. Down

elevator is then applied to accomplish the "outside" portion of

the maneuver recovering in level upright flight; this results in

a lazy or stretched out horizontal figure-eight. Whenever you fly

aerobatics, be prepared to abort the maneuver at any time and return

to level flight even if it means inverted level flight with a dead

engine. Inverted dead stick landings are hard on rudders, but attempting

to get right side up without sufficient speed, altitude and line

tension usually results in a serious crash. Even if you

can resist aerobatics you'll find the Tuholer one of the greatest

flyers yet to invade the scale circle. Several of my friends have

suggested that the Tuholer would make a nice RC model. I must agree

and plenty of radio space is available in the wing center sections

and under the seats. Either way I think you'll like the Tuholer.

<click for larger version>

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted November 20, 2010

|