As

with most other aspects of aeromodeling, ducted fan propulsion systems

have come a long way since the time you had to build the entire

unit yourself. Modern prefabricated ducted fans are molded glass-filled

nylon or carbon fiber that has been engineered, manufactured, and

optimized in every aspect of strength-to-weight, thrust, and dimension

for the intended application and powerplant. It is like the difference

between early radio controlled

helicopters

that were built on hand-drawn plans and built on a lathe and end

mill, and the models you can buy now that practically fly themselves

right out of the box. If you do, however, relish the thought of

designing and building your own ducted fan or if you just like learning

about how the pioneers developed the science into what it is today,

then this article is for you. helicopters

that were built on hand-drawn plans and built on a lathe and end

mill, and the models you can buy now that practically fly themselves

right out of the box. If you do, however, relish the thought of

designing and building your own ducted fan or if you just like learning

about how the pioneers developed the science into what it is today,

then this article is for you. The ducted fan unit to the

right is E-flite's

EFLDF15 electric motor powered unit. It costs a mere $30 from

Horizon Hobby. Using the purpose-built

BL15 brushless motor ($65) on a 3-cell LiPo, you can expect

1.7 pounds of static thrust at 31,000 rpm. Add another cell

in series and increase the thrust to a whopping 2.8 pounds at 40,000 rpm.

Ducted Fans - Scale-like R/C Planes

By P.E. Norman

Author-experimenter P. E. Norman, son Marcus, friend, 5

R/C ducted fan models. |

Having been an ardent flying scale fan since I built my first model

plane back in 1925, it was with mixed emotions that I watched the

rapid progress in jet-plane development after World War 2, spelling

as it did the beginning of the end of the military prop-plane era.

No longer would there be such a wide choice of interesting new prop-driven

aircraft from which to choose new subjects for my scale activities.

But as the years went by and the post-war skies of Britain

became more and more the domain of jet-planes, these beautiful winged

projectiles soon cast their spell. I determined to build flying

replicas and join the Jet Age myself! This was in the early "Fifties"

when very little work had been carried out with model jets. As far

as I could ascertain, the ducted-fan appeared to offer the most

practical source of power ... especially for my own particular style

of model built very rugged to withstand plenty of wear and tear

as well as frequent contact with trees, buildings and Mother Earth!

Intake and efflux (outlet) sizes were an unknown factor,

but extensive bench tests with tubes and cones of various diameters

and tapers, showed that they would have to be of generous proportions.

Restricting the opening at either end caused a substantial drop

in engine rpm and "blow" from the rear end. So from the start all

of my D/F models featured monocoque fuselage construction to permit

the largest possible size fans to be fitted. Observation of other

D/F craft have confirmed that those equipped with small fans (in

relation to maximum fuselage cross section) usually have marginal

performance. Most seem incapable of ROG fights or of gaining much

height after being launched from shoulder level.

Boulton Paul 121. |

With all my models I have always tried to approach something like

scale speed, so they usually fly fairly fast and are heavier than

the average F/F scale type. To continue the same kind of operation

with D/F models, I would have to squeeze every possible ounce of

thrust from the powerplants. Which led me to the next unknown factor

- the actual fan. My first fan of bent aluminum was discarded at

an early stage of testing when a blade flew off at peak rpm and

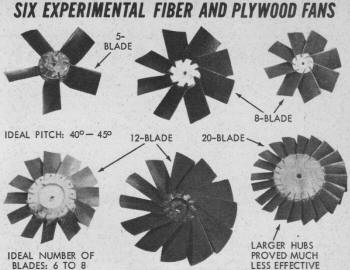

just missed my foot. Fan Design ... Among

the materials I tried for fan blades were 1/16" plywood (quite good),

tufnal, cut-up, plastic bottles (too flexible) and finally fiber.

Fiber turned out to be ideal, so I have used it exclusively with

blade thicknesses varying from 1/32" to 3/32". Fan blades should

be cut slightly oversize and secured in the hub slots with resin

glue and small brads through the hub face. When dry, a disc is bolted

to the front of the fan so surplus portions of the blade tips can

be trimmed off. Blades should be bent gently into a slight camber

and then given several coats of fuel proof dope for protection against

warps and oil soakage. I have tried dozens of different

fan designs, with 3 to 24 blades of various width and pitch setting,

in combination with different hub diameters. Best results have been

with 6 and 8·bladed fans (1" to 1 1/8" width). set at 40· to 45°

pitch in reasonably small hubs. Fan hubs are cut from 3/8" thick

plywood and accurate blade installation obtained by using a simple

jig for aligning hub-slot locations correctly. I make such a jig

from a 1" wide strip of 1/16" aluminum. A hole of the same diameter

as the engine crankshaft is drilled close to one end of the strip,

which is bolted firmly to the plywood hub (already marked with the

blade positions on one face). The strip is bent over at right angles

(so that it rests flat against the circular edge of the hub) and

cut off about 1/2" beyond hub's rear face. A 40° or 45° slot is

cut in the bent-over portion of the strip with a hacksaw and the

hub rotated until the first penciled-in blade location is lined

up with the strip-slot. Then the assembly is secured in a vise and

each hub-slot cut to the desired depth.

A

carefully assembled fan is important, since perfect balance is essential

for maximum fan efficiency. Originally I used "diesel" (compression

ignition) powerplants, but changed to glo-engines when I found the

latter gave much more thrust due to high operating rpm. A large

Volume of air moving through the duct at great speed is desirable

- with as little restriction as possible in the area behind the

fan and at the efflux (rather than a large Volume of air being drawn

into the fan and then being compressed and exhausted through a restricted

efflux). A

carefully assembled fan is important, since perfect balance is essential

for maximum fan efficiency. Originally I used "diesel" (compression

ignition) powerplants, but changed to glo-engines when I found the

latter gave much more thrust due to high operating rpm. A large

Volume of air moving through the duct at great speed is desirable

- with as little restriction as possible in the area behind the

fan and at the efflux (rather than a large Volume of air being drawn

into the fan and then being compressed and exhausted through a restricted

efflux). Fuselage Design ... My first ducted-fuselages,

built almost exclusively of balsa, consisted of 1/8" x 1/4" planking

over 1/8" sheet assembly formers (later removed). Upper and lower

halves were each made in this way then cemented together and covered

with light silk doped in place (after first covering the interior

with similar material). However. this method was prone to soak up

fuel with a consequent reduction in strength and a marked increase

in weight after a few flying sessions. Obviously this wasn't

the solution, so next I tried papier-maché (paper-pulp mixed

with glue) fuselages, but this also suffered from similar defects.

Fiberglass molded bodies proved fairly satisfactory, although they

tended to come out on the heavy side and were likely to fracture

upon a sudden heavy impact. Eventually I turned to 1/32"

plywood, soaked in water to make it flexible (again using 1/8" sheet

assembly formers). Although this is more difficult to form (except

in very simple curves), it proved the best all-round construction

method since it is fairly light and highly resistant to oil soakage.

So all my subsequent D/F models have had bodies of this type. The

fuselage forward of the wing position should always be the strongest

part of a D/F model - and you can afford the extra weight since

nose ballast is usually required anyway. Resin glues (liquid or

powdered) are used, extra strength is obtained in larger models

by using two or three laminations of 1/32" plywood, reinforced by

light nylon or nylon-chiffon attached with the same adhesive. All

hinges, for powerplant, R/C equipment or other items, can be made

from nylon ribbon.

Flying

Surface Design ... Conventional building methods proved

satisfactory for wing panels, stabilizers and fins, although I install

3/16" diameter reed along the wing leading edges and around the

tips as with all my scale models. Full depth mainspars of hard 1/8"

balsa, strengthened by gluing 1/32" plywood on one face, provide

a very tough wing structure. Thin, flat-bottomed sections

should be used for the wings, installed at 1.5° to 3° to the thrust-line.

High set stabs usually require a similar amount of negative incidence.

Wing boxes are best made from 1/16" or 3/32" plywood, with hard

1/4" wide balsa spacers at the edges and the complete boxes securely

bound and glued with nylon thread. Knock-off wing panels

and stabilizer are best, wings being retained by built-in spring

clips, the stabilizer by rubber bands stretched over the top from

hooks set in fin leading and trailing edges. The latter is for high-mounted

stabs. When the stab is lower or on top of the fuselage, separate

knock-off stab panels can be mounted in a similar way to the wing

panels. It's usually best to mount the fin integral with fuselage.

light silk covering, or preferably nylon-chiffon, is ideal.

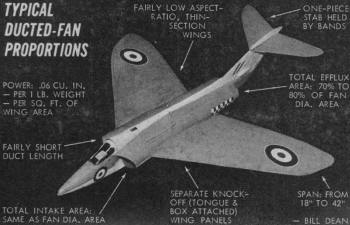

Powerplant

Considerations ... A good guide to the amount of power

required is to aim for .060 cu. in., per 1-lb weight, per sq. ft.

of wing area. This is assuming a well-streamlined clean design with

a fairly low aspect-ratio wing. Keep in mind that long fuselage

ducts have the disadvantages of increased air-friction and weight,

so keep ducts as short as possible. Although air-flow straightener

vanes (mounted at an angle of 30° close behind engine on a streamline

balsa cone) do increase thrust slightly, they also make duct cleaning

difficult. Down-thrust-vanes of 1/32" plywood should be installed

in the extreme end of the duct efflux to permit power flight trimming. Powerplant

Considerations ... A good guide to the amount of power

required is to aim for .060 cu. in., per 1-lb weight, per sq. ft.

of wing area. This is assuming a well-streamlined clean design with

a fairly low aspect-ratio wing. Keep in mind that long fuselage

ducts have the disadvantages of increased air-friction and weight,

so keep ducts as short as possible. Although air-flow straightener

vanes (mounted at an angle of 30° close behind engine on a streamline

balsa cone) do increase thrust slightly, they also make duct cleaning

difficult. Down-thrust-vanes of 1/32" plywood should be installed

in the extreme end of the duct efflux to permit power flight trimming.

Getting down to cases for typical model! powerplant combinations:

18" to 24" wing span suits .049 engines; 24" to 30" span for .09's;

30" to 36" span for .15's and 36" to 42H spans for .19''s. Most

of my D/F flying with American powerplants has been carried out

with Cox and Fox products. Typical fan-diameter/powerplant

combinations are 3" for .049's; 3 3/4" for .09's; 4" to 4 3/8" for

.15's; 4 1/2" to 4 5/8" for .19's. For 3" dia. fans, 6 blades should

be used - 8 blades on anything larger. Both 3" and 3 3/4" fans (1/32"

thick blades) need 40° pitch - while the larger sizes (1/16" thick

blades) can take from 40° to 45° pitch. It's worth while

making up several fans of varying pitch and picking out that best

suited to a particular model, after flying tests. Although there

is quite a bit of work involved in these fans, remember that the

chance of breaking one in a crash (except in a complete write-off)

is very slim. A range of commercial fans of this type are made in

Britain by Veron - some U.S. mail order dealers carry them.

Intake area should be as close to fan-diameter as possible;

efflux area should be from 70% to 80% of the fan-diameter area.

Direct nose intakes or "elephant-ear" intakes (forward of wing)

are far more satisfactory than wing-root intakes. The circular intake

and efflux areas may be changed into elliptical shapes by cutting

1/2" wide strips of thin card and overlapping the ends to form circular

rings, then squashed slightly to provide the desired section patterns.

Combined

plywood engine/wing-tongue/fuel-tank mounting-plates must be absolutely

rigid and well braced to the lower fuselage half to avoid any vibration.

For .049 to .09 engines use 1/8" plywood; for larger motors, 3/16"

plywood. Fan rings of 1/32" plywood (1" wide) should be glued to

inside of duct, with a minimum of fan clearance, to avoid blade

tip losses. Engine, fan and tank must be easily accessible for cleaning

and inspection, since the oily duct interior retains an amazing

amount of dirt and grass picked up during landings. Combined

plywood engine/wing-tongue/fuel-tank mounting-plates must be absolutely

rigid and well braced to the lower fuselage half to avoid any vibration.

For .049 to .09 engines use 1/8" plywood; for larger motors, 3/16"

plywood. Fan rings of 1/32" plywood (1" wide) should be glued to

inside of duct, with a minimum of fan clearance, to avoid blade

tip losses. Engine, fan and tank must be easily accessible for cleaning

and inspection, since the oily duct interior retains an amazing

amount of dirt and grass picked up during landings. It's

a good idea to fit engine exhaust stacks with very light aluminum

shrouds, to prevent dirt from entering the cylinder head. Engine

holding bolts should be locked to guard against vibration. All access

hatches must close flush and hold securely, since a hatch opening

in flight will most certainly result in a spin or dive-in.

Flying Ducted Fans ... Correct balance should

be obtained by adding weight (I use empty cement tubes) to the nose.

Before leaving the workshop, become well acquainted with starting

your engine by means of a cord starter, find the best needle setting

for maximum rpm and check the duration of the fuel tank. A D/F model

without landing gear should push itself slowly across the floor

under full power. In addition, to your usual tool kit, starter

battery, you should take along a spare starter-cord, glo-plugs and

fan. Before starting engine, remove from intake front anything which

might get sucked in and damage the fan or engine. If possible,

fly over reasonably long grass. Try to choose a time when a slight

breeze is blowing as these models tend to have a fast gliding speed.

Aim for a dead-straight glide, without any suggestion of a stall

- correcting any turning tendency by small celluloid or plastic

trim tabs attached to the rudder and one wing tip. Avoid maximum

power for the first few flights, as slight adjustments may be needed

on the downthrust-vanes (to prevent stalling) or to the trim tabs

(to correct too sharp a turning tendency). Types

Built ... Since turning to D/F models, I've built and flown

11 scale and 13 scale-like F/F types - followed by 7 near-scale

R/C types. These divide into four flying-surface configurations,

as follows: #1) Swept-wing; #2) Delta wing; #3) Swept-wing with

swept-stab; and #4) Deltawing with delta-stab. Of these, type #3

models have proved the fastest and most stable, with type #4 following

close behind - they need no dihedral, provided the stabs are set

high. All types have performed well and most models built are still

in good flying shape. Apart from the four general categories

detailed, my D/F experiments have been concerned with three different

series of models. The first set included models from 30'" to 36"

span, usually powered with a .15 engine. My second series consisted

of smaller models of from 23" to 28" span each with an .09 or similar

powerplant. The third series covers most of my present D/F activities

- R/C designs from 32" to 44" span, powered with an engine from

.09 to .35 size.

Scale

Ducted-Fans ... the first F/F scale D/F model I tackled

was the MiG 15 powered by a .11 diesel (driving a 6-blade fan),

It had a span of 36", weighed 27 ounces and was very stable, with

a moderate rate of climb. This was followed by two more MiG 15's,

of slightly smaller size (32" span), but with more powerful .15

diesels. One used conventional balsa construction (like the first

MiG) and weighed 26 ounces; the other had a fiberglass fuselage

and weighed 29 ounces. Both differed from the original MiG in that

they featured integral fins and separate knock-off stab panels,

instead of a single knock-off fin/stab assembly. Scale

Ducted-Fans ... the first F/F scale D/F model I tackled

was the MiG 15 powered by a .11 diesel (driving a 6-blade fan),

It had a span of 36", weighed 27 ounces and was very stable, with

a moderate rate of climb. This was followed by two more MiG 15's,

of slightly smaller size (32" span), but with more powerful .15

diesels. One used conventional balsa construction (like the first

MiG) and weighed 26 ounces; the other had a fiberglass fuselage

and weighed 29 ounces. Both differed from the original MiG in that

they featured integral fins and separate knock-off stab panels,

instead of a single knock-off fin/stab assembly. These two

new models had greatly increased thrust output and really got up

there in a hurry. They were soon followed by a string of similar

proportion .15 diesel powered scale types - including the Boulton

Paul P.111 and P.120 deltas. Ouragon Mystere and the Grumman Cougar.

R/C Ducted Fans ... Some of the most exciting

flying I've ever experienced has been with R/C ducted-fans. They

are beautifully smooth in flight and respond to control immediately.

To date, I have only used rudder, but intend to try multi on future

projects. The present models are fast (about 50 mph). Since they

have little torque or gyroscopic effects they are quite easy to

fly. They climb well and settle easily into a fast, flat glide,

followed by smooth belly landings. Low passes downwind at a height

of 2 to 3 feet with a 50-60 mph groundspeed stir anyone who ever

nibbled cement off his fingertipsl My first D/F type fitted

with R/C was a .09 diesel powered delta-wing/delta-stab aircraft

of 32" span and allup weight of 28 ounces. A 4.5 volt transistorized

receiver was carried in the nose, pencells in the fuselage "spine"

and a very small home-built escapement housed in a fin-blister.

Initially flown in '59, this one took first place in an R/C spot-landing

contest and also made un-assisted ROG fights, using a take-off dolly.

A larger 36" span version of 350 sq. in. wing area was next powered

by a Cox .15 Olympic; she weighed all-up 40-0z. Subsequent

R/C designs have all been swept-wing/swept-stab using a Max .15

then a Fox .15 (34" span, 36 ozs.), Fox .19 (39" span) and Fox .35

Combat (44" span, 3.75 lb) powerplants. The .19 and .35 models develop

enough thrust for easy loops and wing-overs.

Scale-Like

Ducted Fans ... Most of my F/F semi-scales have been based

on well known British, American and Russian jet-fighters. Sometimes

I borrowed features from different types to obtain characteristics

that fitted in with the type of model size/powerplant/fan combinations

I wanted. Scale-Like

Ducted Fans ... Most of my F/F semi-scales have been based

on well known British, American and Russian jet-fighters. Sometimes

I borrowed features from different types to obtain characteristics

that fitted in with the type of model size/powerplant/fan combinations

I wanted. Included among the more interesting semi-scale

D/F types I've turned out is a .15 powered Douglas Skyray delta

of 31" span and 30 ounces weight - built to obtain very large intakes

and efflux openings - with a thinner-than-scale fuselage nose, which

tapers sharply at the point it merges with the large intakes. It

flies at very high speed with a rapid rate of climb, has remarkable

stall recovery-the latter is an outstanding and rewarding feature

of all delta and tailless types. After many .15 powered

models, I decided to tackle a series of smaller designs, with a

view to closer scale speed performance. Although the larger ships

were quite fast, they did not reach 60 mph - which would be the

scale speed of a 36" span model when compared with a 36 ft. span,

700 mph-plus fighter. Since a 24" span model of the same type would

have to obtain only 40 mph for scale speed, I decided to "think

smaller" and this resulted in a delightful delta-wing/delta-stab

D/F of 27.5" span and 21 ounces weight. This model, dubbed

"Javahawk," was a blend of the British Javelin and the American

Skyhawk fighters. Fuselage and duct side profile consisted of a

straight underside and gently curved top to give built-in down-thrust

effect under power. It once turned in 7 minutes on the glide alone!

A lighter version can be trimmed to perform consecutive loops until

the fuel runs out. Both models definitely fly at scale speed!

Then there is a swept-wing/swept-stab job based on the Supermarine

Scimitar. Powered with a .09 diesel, spanning only 27" and weighing

20 ounces, this one has ultra-thin 5% wing panels and is very, very

fast. It belongs to the same "family" which culminated in the 34"

span, .15 powered "Rapier" F/F (or R/C) design - plans of which

are due to appear in a forthcoming American Modeler. In

a report of this type, I've naturally had to gloss over many points

of design and construction. Should you want to get the old drawing

board and start off with a D/F dream-ship of your own the "Rapier"

plans will fill in most of the gaps. But you'd be wiser to build

the "Rapier" first, as it incorporates the experience gained through

thousands of flights logged with more than thirty D/F models during

the past ten years.

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted September 28, 2013

|