|

The 1950

Academy of Model Aviation (AMA) regulations listed four

model engine displacement ranges: Class A: .000-.200 cu. in., Class B:

.201-.300 cu. in., Class C: .301-.500 cu. in., and Class D: .501-.650 cu. in. Notice

that there was no Class ½A or Class ¼A. That jives with this 1950

article in Air Trails magazine where the K&B Torpedo .049 engine is highlighted.

It claims, "Half-A engines started out a short time ago as a mere novelty, but they caught

on fast and every manufacturer was in a hurry to get one on the market." It is hard to imagine

a time when the .049, .020, and .010 engines were not around, but machinery capable of achieving

high production levels of engines with such tight tolerances were not as available. Sadly,

only .049 engines are still manufactured (see Cox and Brodak), although a search on eBay will turn up many vintage examples

for purchase.

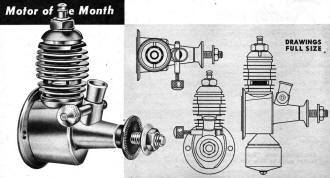

Motor of the Month: K&B Torpedo .049 Engine

K&B hits the top of the Half-A (AA) Class with a worthy addition to

their stable of racing steeds

Not to be outnumbered by the Three Bears, K&B Mfg. Co, has completed its three Torps.

A Torp must be a smaller animal than a bear because it starts at the .049 size and goes down,

including the Torp Junior and the K&B Infant. All three engines look very much alike,

being machined from aluminum bar stock rather than the usual aluminum castings. Special glow

plugs were used in the two smaller engines, but the new .049 has a conventional short plug.

Motor mount dimensions are the same on all three engines.

A top speed of 15,300 rpm was obtained with the glow plug supplied by the manufacturer.

Hot mechanics from the speed circle could probably improve on this by opening the bypass ports

slightly. The large rotary valve and crankshaft opening should be adequate for higher rpm.

Base compression is very high, and this would help to feed fuel at increased speed.

Sport, free flight, and stunt enthusiasts will be impressed with consistent running during

flight. The eight-inch fuel level test is the highest for any small engine, and compares well

with engines in the .030-.049 displacement bracket. This means the engine will continue to

run steady when fuel flow changes due to centrifugal force, changing air pressure at tank

vents, or other disturbances in flight that usually cause an engine to slow down.

The test was started with a 6/3 propeller. After two hours of running, the engine was still

tight and it would overheat when adjusted slightly lean. It showed very little change from

its new condition. However, changing to a 5½/3 plastic propeller produced some fast results.

Speed continued to increase for five minutes, then the engine was thoroughly broken in.

This high-speed break-in did not hurt the engine in any way, as it retained a good compression

seal and still ran well on a large propeller. Both the Baby Torp and the .049 Torpedo have

the rare quality of running well at high speed and still remaining tight enough for slow-speed

use, such as a free flight ship. During the test, starting was very easy whether the engine

was cold or red hot from a hard run.

Half-A engines started out a short time ago as a mere novelty, but they caught on fast

and every manufacturer was in a hurry to get one on the market. As long as it ran well enough

to pull a small airplane customers were satisfied. However, recent tests for AT Motor of the

Month articles show a sudden jump in the performance and design of the A/2 engines. Many of

the tricks used in larger models such as a low stroke bore ratio, special port designs, and

lightweight parts are being used to increase speed and power. Mechanical construction is improving

with such details as pressure die castings, steel bushings, and many hardened steel parts.

It appears that a complete round of new miniature engines has started, and we will probably

hear from most of the leading engine manufacturers in a short time. Half-A classes should

show a big advance during the next flight season.

Torpedo .049 Engine Data

Performance. Bare weight, less tank: 1.37 oz. Propellers - 6/3 wide blade wood plastic,

10,800 rpm; 5/4 wide blade wood, 12,500 rpm; 5 1/2 /3 plastic 13,700 rpm; 5/3 wood, 15,300

r pm. Fuel: any hot blend. Fuel level test: 8" at 12,500 rpm.

Design Data. Displacement: .049 cu. in. Class: A /2. Stroke: 0.380. Bore: 0.406 Stroke-bore

ratto: 0.935. Compression ratio head: 5.8. Compression ratio base: 1.62. Port area intake

.0154 sq. in.; bypass 0.00523 sq. in.; exhaust 0.0370 sq. in. Ignition: Torpedo glow plug

(short).

Construction Features. Bearings - crank shaft: aluminum; crankpin: aluminum: connecting

rod, ball joint; aluminum & brass.

Parts all machined from bar stock - no castings.

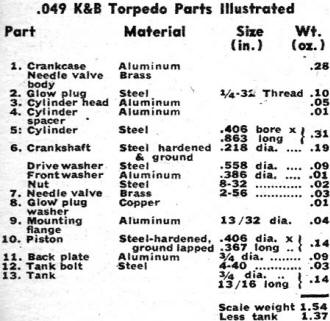

.049 K&B Torpedo Parts Illustrated

IMAGE HERE

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted

|