|

As

electric power is increasing in popularity for model aircraft locomotion

due to significant advances in motor and battery technology, internal

combustion engine use is decreasing - at least as a percentage.

For those modelers who still indulge the often temperamental habits

of those engines, this article from the American Aircraft Modeler's

For the Tenderfoot series is a good primer on how to break in and

adjust them for long life and reliable runs. My own conversion to

electric power has been purely for the sake of convenience; there

is no substitute for the sound and smell of a model airplane engine

screaming away with the fragrance of hot castor oil emanating from

the exhaust port. Gentlemen, Start Your Engines!

Engine starting, operation, break-in, and trouble-shooting

is a matter of technique and practice. Here's how an expert does

it. G. B. Telfair and William M. Johnson

Gentlemen,

start your engines! Each Memorial Day this cry, echoing across the

Indianapolis Speedway, brings a score of racing power plants roaring

into life at the start of the Indy 500. But, on the model airplane

flying field, such is often not the case. The Tenderfoot, who has

just bought his shiny, new model airplane engine, is having his

difficulties getting it to run. Gentlemen,

start your engines! Each Memorial Day this cry, echoing across the

Indianapolis Speedway, brings a score of racing power plants roaring

into life at the start of the Indy 500. But, on the model airplane

flying field, such is often not the case. The Tenderfoot, who has

just bought his shiny, new model airplane engine, is having his

difficulties getting it to run. As frustration sets in,

and the Tenderfoot and his Dad are about to decide that they're

stuck with a lemon, an Old Modeler enters the picture. The Old Modeler

goes through a few motions, flips the propeller a couple of times,

and the previously obstinate engine leaps into life and purrs like

a kitten. "Now, what did he do that I didn't?" wails the

Tenderfoot.

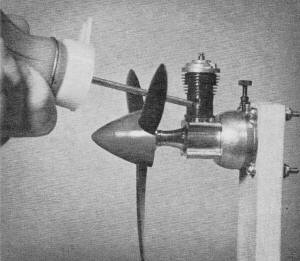

With engine mounted on a board clamped to an outdoor bench,

practice starting and adjusting it before mounting it in

a plane.

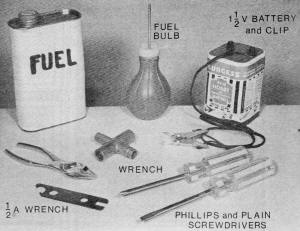

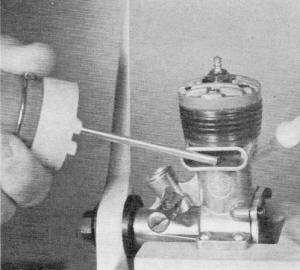

Use fresh sport fuel, new battery, clean glow-plug clip,

and have all the tools for your engine. The wrench is by

Austin Craft.

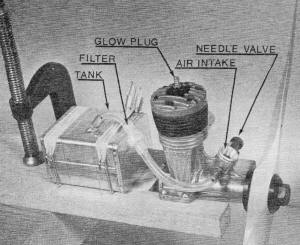

Tank size is chosen for convenience only, but note that

the tank is about even horizontally with the engine's needle

valve.

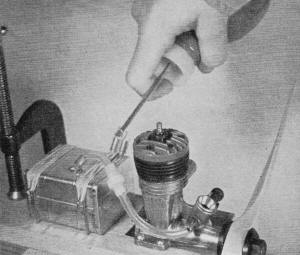

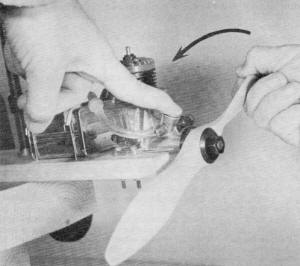

Bolt a radially mounted 049 engine to a sturdy piece of

wood which is then clamped in the work-bench vice. Priming

method shown.

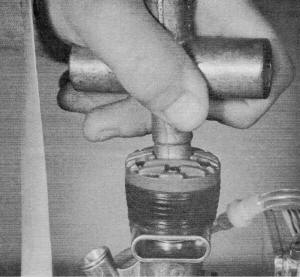

When priming the larger engine, place the prop so that the

piston is at its lowest position, squirt a few drops into

the cylinder.

Choking the engine means closing the intake or carburetor

opening with your finger, while holding and rotating the

prop a full turn.

Opening the needle valve will run your new engine slower

with a rich mixture. It will run cooler and have more lubrication.

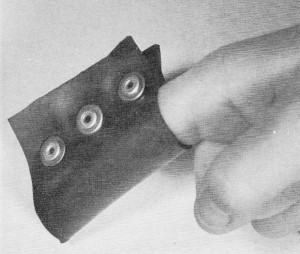

Engines do backfire and fingers can get cut. A simple inner-tube

rubber finger guard is easy to make. Use it on all sizes

of engines.

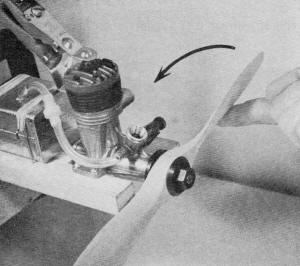

Set the needle valve per article, then clip and flip. With

finger behind prop. pull across forcefully as quickly as

possible each time.

With engine running, adjust needle valve. To run faster

turn valve clockwise. This leans the mixture by reducing

the fuel flow.

Check the plug if the engine won't start. If it lights up,

then both the battery and plug are good, but if not, check

the battery.

Try new plug only if your battery is good. Always use wrench

when installing plug or tightening prop nut. Just get plug

snug. |

In this article, we'll try to give you the answers to his question.

Any experienced modeler can tell you that there's no real difficulty

in operating a model airplane engine. You just have to attend to

some details. Properly cared for, all modern sporting-type engines

will start easily and consistently, will run smoothly, and will

have a long and satisfactory life. So, to get started properly,

study the accompanying photographs as well as this article. We've

based the photos on a popular sport-type engine. However, the principles

are applicable to all conventional model airplane engines.

In addition to the how-to-get-started photos, we've included

ideas on what to do if the engine seems not to want to start. And

we've included a few pointers on operation to assure a long and

useful engine life. If you have a new engine, remember that

all new engines require careful break-in if they are to continue

to give reliable operation. So, please be familiar with the section

"Breaking in the New Engine" before you set out to start it for

the first time. Take it easy, don't overspeed it! There'll be time,

later, to demonstrate its high performance. A few

starting pointers: Priming causes most beginners to stumble.

A couple of turns of the prop with the air inlet choked, plus a

few drops of fuel in the exhaust port is usually all that is necessary.

Some engines may require only the initial choking, while others

may require a juicy exhaust prime. You will need to become familiar

with your particular engine. When you start flipping the

propeller and hear a mild "pop" every flip or so, the engine is

trying to start, so keep cranking! A new engine can be stubborn

and may require quite a bit of cranking before finally catching.

So don't be discouraged if it doesn't fire right away. Many perfectly

good engines have been returned to hobby shops because their inexperienced

owners did not recognize this trait. The experienced modeler's

trick - to tell when the engine is ready to fire - is a useful one.

Don't worry about the propeller being pulled out of your hand; the

explosion force isn't that powerful if you have a firm grip on the

blade. When you feel the light "catch," a few flips should have

the engine off and running. When your engine starts it probably

will run roughly, emitting much blue smoke and raw fuel. That's

because the needle valve is set too far open (too rich). Close the

needle valve slowly (rotate clockwise) and the engine will start

to run smoothly. Disconnect the glow-plug clip. If the engine slows,

the mixture is still too rich, so reattach the clip and close the

needle valve a touch more until the engine runs smoothly with the

glow-plug clip removed. As you close the needle valve further, the

engine will speed up and reach a "peak." Beyond this peak, as the

needle valve is closed further, the engine will slow again as the

mixture be-comes too lean. Don't run the engine at these

over-lean settings, because it will overheat and damage itself.

A well-broken-in engine runs best a a needle-valve setting about

one-half turn richer than the setting for peak rpm on the ground.

In flight, the air stream will provide enough extra air to lean

the engine out to about its maximum speed, When it

wont start! No matter how carefully you have prepared, the time

will come when you crank, and crank, and crank, and nothing happens.

While you're resting your tired arm check a few common causes:

- Are the battery wires loose, at the battery or at the glow-plug

clip? Is the battery run down?

- Are the glow-plug clip contacts clean? Dirt there can prevent

the current from flowing.

- s the fuel line kinked so the fuel won't flow? Soft rubber

tubing often does this. Is the line loose from the engine or

from the fuel tank? Has the fuel line contacted the hot cylinder

and burned a small hole in the tubing wall?

- Is the propeller positioned correctly? Is the propeller

secure on the shaft?

- Are you using the propeller recommended in the engine instructions?

An over-large propeller can be too heavy for the engine to swing.

If your starting preparations and these points show up O.K., then

it's time for serious trouble-shooting. Needle valve set

too lean: A quick, screaming burst, followed by a sudden stop means

that not enough fuel is reaching the engine. All it's doing is using

up the priming fuel. If the fuel line isn't kinked or loose, open

the needle valve another turn and try again after repriming. We've

found a few individual engines that used needle-valve settings quite

different from the manufacturer's recommendations. Dirt

in the fuel supply: If the engine still runs out the prime and quits,

check for dirt clogging the fuel line or the needle valve. If you're

using transparent fuel line, inspect it carefully for specks of

dirt inside, particularly where the tubing joins the needle valve.

These particles can come from several places. An over-aged

fuel bulb may be starting to shed rubber crumbs into the fuel as

you squirt it into the tank. If the fuel tank is an old one, it

probably has dried fuel residue in it, which flakes off when the

new fuel hits it. And dirt may have drifted into your fuel can.

Reputable fuel manufacturers are carefully clean, but if you let

the fuel can sit around with the cap off, dirt will get into it.

Save yourself a great deal of trouble by using a filter between

the fuel tank and the engine. Clean the filter after every flying

session, being careful not to lose the little screen that's inside

and is the heart of the filter. Dirt can be flushed from

the fuel line by squirting a little fuel through it with the fuel

bulb. Or replace the line with new tubing. Then, remove the needle

from the needle valve and attach the fuel bulb directly to the needle

valve inlet. Squirt fuel through the valve to flush out any dirt.

To remove dirt from the fuel tank, re-move the tank from

the test block or the model and flush clean fuel through it. In

the case of a small engine with an integral tank, carefully remove

the tank, following the manufacturer's instructions, and flush it

out with clean fuel. Just be careful that you don't introduce more

dirt than you remove! Loose parts: After

several cycles of the heating and cooling to which a model engine

is subjected, cylinder-head bolts and crankcase bolts and glow plugs

become slightly loose. This looseness can cause the engine to leak

enough to prevent starting. Tighten them up (with the correct screwdriver

or wrench), including the engine-mount bolts, before and during

each flying session. Glow plug troubles:

If the engine shows no inclination to fire, either from the beginning,

or after one of those screaming, too-lean bursts, first check the

glow plug. It may have burned out or have been the victim of vibration.

The easiest check is done by attaching the glow-plug clip and looking

into the exhaust port with the piston down. An orange glow shows

that the plug is O.K. If you're still not sure, remove the plug

and place it across the jaws of the clip as shown in one of the

photos. The plug element should light up (in bright daylight you

may have to shade it to see the glow). If it doesn't glow, select

a new plug, but test it before putting it in the engine. (Funny

thing, the battery might have been dead all along, although new

plugs have been known to be faulty!) If the engine quits

after the glow-plug clip has been removed, the plug may not be holding

its glow in the heat of the combustion chamber. It may be just "tired"

from over age or too much high-speed, high-temperature running.

The only cure is a new plug. Sometimes the glow-plug element,

through use, gets against the plug wall and causes a short circuit.

If this appears to have happened, gently use a straight pin to pry

the element away from the plug wall. This may restore the plug and

save you 50c. Always follow the engine manufacturer's recommendations

for glow plugs. Small engines usually take short plugs; large engines

usually use long plugs. A long plug in a small engine can interfere

with the piston travel, at the least keeping the engine from starting

and, at the worst, damaging the piston. Flooding:

Probably the most common cause of starting difficulties is flooding.

This means that there is so much raw fuel in the engine that the

fuel-air mixture reaching the combustion chamber is much too rich.

This mixture won't burn properly, and also tends to quench the glow

plug. Flooding is caused by over-priming, or a too-open setting

of the needle valve, or both. It can usually be recognized by the

raw fuel being thrown out the engine exhaust and being spit back

through the air inlet when the propeller is flipped. A light

or moderate flooding condition often will clear itself by evaporation

while you're checking the glow plug, fuel lines, etc. So, after

making these preliminary checks, it's a good idea to try a start

with-out any prime, on the chance that there's enough fuel remaining

in the engine for a start. A lightly flooded engine may

emit one loud "bang" and stop when it is cranked. Invariably, the

force of this backfire has loosened the propeller. Remove the glow-plug

clip, reposition the propeller, reattach the glow-plug clip, and

try again. If the engine doesn't respond after a dozen flips, reprime

and try again. If it still won't cooperate, check the glow plug;

the force of the backfire may have damaged it. Heavier flooding

is best cured as follows:

- Disconnect the fuel line and close the needle valve.

- Connect the glow-plug clip.

- Crank until the engine starts. It will run roughly for a

short burst and quit.

- Continue cranking until the engine fires again, runs longer,

smoother, and then stops.

- Reconnect the fuel line, open the needle valve, and proceed

to start as usual.

In cases of very heavy flooding, remove the glow plug and invert

the engine, keeping the inlet low. Rotate the propeller by hand

and fuel will flow out the various openings. Loose

needle valve: If the engine starts well, and runs for a

while, and then starts to slow or run erratically, check the needle

valve. It is probably loose. If the spring clip that retains the

needle is not tight enough, the needle can vibrate open or closed.

Sometimes the spray-bar, into which the needle valve screws, becomes

loose in the air inlet and turns so that its spray hole no longer

points down into the engine. Reposition and tighten these parts,

making sure that the spray hole points directly down the air inlet.

Breaking in the new engine: If you are

starting with a brand-new engine, don't try to get top rpm's from

it until it has had a chance to break in. All you'll accomplish

will be overheating and damage to the engine. This damage will not

show up right away, but it will show up, eventually, in drastically

reduced engine life. There's no trick to breaking in a model

engine. Just run it at a relatively low speed for several tanks

of mild fuel, letting between each run. The first two or should

be only about 30 to 60 seconds. Then, work up through a few runs

to full tankfulls. Control-line modelers often put a new engine

in a trainer after the first couple of test-stand runs, and complete

the break-in program with a rich mixture in flight. The airflow

around the engine keeps it from overheating, As before, let the

engine cool between runs. As the break-in progresses, the

engine performance gradually improves the running characteristics

become smoother and smoother, and the engine becomes easier to start.

You can tell if your engine is properly broken in by practice-flipping

the propeller against the engine compression. If the propeller bounces

back, nice and springy, the engine is broken in properly.

Operating tips: This may sound like a broken

record, but treat your engine right and it'll treat you right. It

never hurts an engine to be run slightly rich. On the other hand,

it can be quickly ruined by over-heating from flight after flight

at high speeds with an over-lean mixture. Don't be fooled by the

way engines are operated in Speed, Rat-Race, Combat, or Navy Carrier

events. The contestants are demanding the most the engine can give

and expect a relatively short life. In Sunday flying, though,

there's no need to beat the engine to pieces. Remember, when the

model is in flight, the engine receives more air than it does on

the ground, so it runs leaner. Therefore, set the needle valve about

one-half turn richer than the setting for peak speed on the ground,

and it won't over-lean in the air. We shouldn't have to

mention it, but every so often someone tries to fly with a nicked

or split wooden propeller. For safe-ty's sake, don't! The prop is

likely to fly apart. Aside from pieces of wood flying like bullets,

the brief, violent vibration that occurs before the engine stops

has been known to rip the engine right out of the model.

Nylon

propellers are popular because of their durability. However, if

the tips become frayed, they should be trimmed and the propeller

rebalanced. Otherwise, the unbalance will rapidly wear the crankshaft

bearing. If you use a "chicken stick" (a short, rubber-padded

wooden stick), don't bat at the propeller with it to start the engine.

The blow can damage the propeller. If the propeller nut

becomes stiff to turn, and you have trouble removing it (the result

of cross threading or crash damage), insert a hardwood stick or

a broken propeller blade through the exhaust port into the combustion

chamber to hold the piston and crankshaft while the nut is turned.

Don't use a screwdriver for this; it will damage the piston and

cylinder liner. When your model is sitting on the ground

between flights, keep a clean cloth over the engine to exclude dirt

and grit. Then, after each flying session, as you clean the model,

clean the engine. Remove the excess oil and accumulated grit and

dust; they have a habit of drifting into the engine's working parts.

Plug the air intake with soft cloths or tissue and encase the engine

in a plastic bag. Properly cared for, your engine will reward you

with many pleasurable flying hours.

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted February 3, 2013

|