|

Multi-cylinder model aircraft engines add an incredible degree of

'wow factor' to any model, whether inline, opposed, or radial. From

a functional perspective, multi-cylinder engines are notable smoother

in operation because when properly configured the pistons are moving

in opposite directions and therefore tend to cancel each other's

mass acceleration. More cylinders gets more vibration cancellation.

Torque effects are the same as for any equivalent displacement engine

as engine speed changes. The other great advantage of a multi-cylinder

engine is better idling characteristics. Producing a multi-cylinder

engine take more than simply coupling two or more engines to the

same thrust line since timing issues, even with glow engines than

have no separate ignition systems, perform better when the entire

engine is designed to coordinate all cylinders. This article covers

many different configurations. Who wouldn't like any one of these

babies sitting on display?

Multi-Cylinder Engines

It is a known fact that vibration all but disappears when

another cylinder is added. In his research and development, the

author also achieved low dependable idle. Explained are the results

obtained from various arrangements-feasible if you can use tools.

By William Woodall

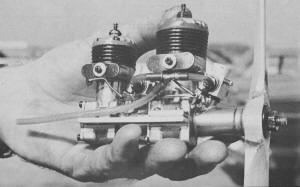

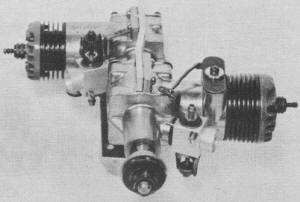

Linked-together engines of different displacements

may be the ideal, Bill believes. This example consists of a McCoy

.35 cylinder in front, with McCoy .19 for rear. Separate crankcases

as well as carburetion.

Photos by Lane Bros. and John Schneider.

A new era for RC flying is here. First is the improved airplane

capable of unbelievable speeds and maneuverability, yet docile enough

to land at reasonable speeds. Second, the excellent proportional

radio equipment now available makes intricate and precise maneuvers

possible. Third, improved RC engines give the airplane performance

and respect far more than once thought possible.

In the field of model engines there are mainly two improvements

to be sought. One - less vibration; two - low, dependable idling.

Like "the jewels of the sea" we have the "jewels" of the model engine

industry at our finger tips just waiting to be developed.

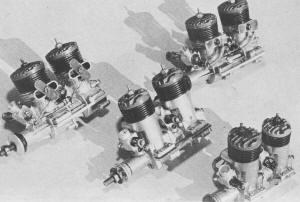

Examples of alternate firing experiments, Mac

.35-.19 (above), and two O.S. 30's (below) which indicate better

idling, linear throttling compared to simultaneous-firing opposed

twins. Separate tubing from bottom of tank to each carburetor a

necessity. There are no starting difficulties; fuel consumption

about equal to equivalent single.

I will endeavor, though crudely, to present a method by which

certain standard single cylinder RC engines can be joined to form

multi-cylinder engines, along with various combinations of displacements

and firing orders. The following classification will indicate those

combinations under consideration.

1) Alternate-firing twin-cylinder engines of equal and unequal

displacement; 2) Simultaneous-firing (opposed) twin-cylinder engines

of equal and unequal displacements; 3) Alternate-firing three-cylinder

engines in-line - that is, one cylinder behind the other - of equal

or unequal displacements.

Two things are to be gained from the end results of joining two

smaller engines together. They are: 1) Less vibration, 2) Lower

dependable idling. One does not gain more power than expected from

equal total displacement as compared to a single engine.

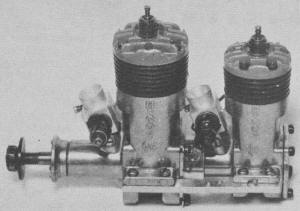

Simultaneous opposed twins, two Max .30's.

Classification 1: Several alternate-firing engines were joined

(each cylinder firing at exactly 180 degrees to the other); in other

words, each cylinder fired once every time the prop made one complete

revolution. The first engine was of equal displacement using two

O.S. Max RC .30's. The next alternate firing engine was of unequal

displacement - a .35 McCoy RC with a .19 McCoy RC in the back position.

Both combinations ran smoothly and idled nicely.

Classification 2: By separating the two alternate-firing engines

and rotating them 180 degrees and re-assembling, I formed two simultaneous-firing

engines - both combinations ran smoothly but, there was an obvious

difference in dependable idling. These engines would not idle as

low as the alternating-firing engines.

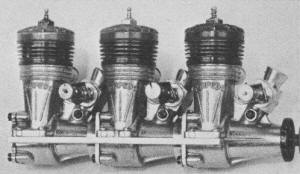

Classification 3: This combination was composed of one K&B

.23 RC and two K&B RC .19's, one behind the other in this order.

The firing order was 1-3-2 cylinders at 120 degrees to each other.

I had to solicit the use of a starter to wind this combination

up. Its "whine" resembles that of a six-cylinder car motor. I see

no real need for this three-cylinder engine at present, but just

wanted to prove to myself that almost unlimited combinations of

engines can be joined together using this method.

Another simultaneous opposed twin, two Max .30's

. These are the same engines used in the assemblies in top photo.

During many hours of flying and bench testing of various combinations

of engines several observations were made in respect to the desired

improvements; they are as follows: 1) Vibration markedly decreased

with both alternating- and simultaneous-firing engines; 2) Dependable

low rpm's in alternate-firing engines is about half that of the

simultaneous-firing engines (these measurements were made with an

electronic tachometer); 3) Linear Throttle - which should be of

particular interest to the rudder-only flyers - where throttle is

elevator.

The alternate firing engine seems to be more promising in the

direction of the "ideal" RC engine. It was also noted that engines

linked together of unequal displacement will tolerate each other

nicely and operate as a unit beautifully. These unequal displacement

combinations may well be the right approach to the "ideal" rather

than the equal displacement combination.

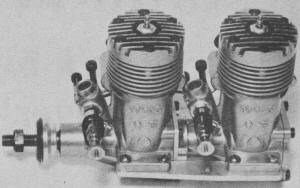

Simultaneous opposed twin, and Mac .35 and .19.

All engines used in these tests were standard RC engines - of

course, their crankcase pressures, etc. were separate. This setup

certainly has its advantage over a single crankcase where both cylinders

are fed from a common crankcase.

The choice of alternate firing engines in the .60 category tested

thus far is two K&B 29's converted for RC operation. Fuel consumption

is about the same as the average single-cylinder engine of equal

displacement. Using an electronic tachometer with the engine on

a testing bench, 12x5 Top Flite prop, 5 per cent nitro-methane in

3:1 methanol and oil fuel, the following rpm's were noted: dependable

idling was 1300 and top speed 10,500. With hotter fuel I feel sure

top rpm could be raised.

Operation: No combination of engines presented any starting idiosyncrasies

- no more than one finds with the single-cylinder engine. The carburetor

adjustment is not difficult-about the same procedure as would be

followed with single-cylinder engines. I do feel that a separate

carburetor for each cylinder has a definite advantage of providing

finer adjustment to each cylinder's need. Separate tubing from bottom

of tank to each carburetor is a necessity - to prevent one cylinder

from starving the other out and consequently causing the engine

to stop.

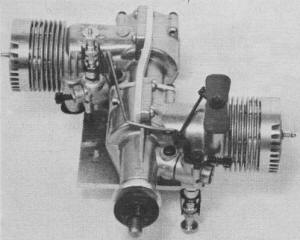

Two K&B .35's (left);

two K&B .29's (upper right); two

McCoy .29's (center); McCoy .35 and

.19 (lower right). Assembly instructions

outlined in text.

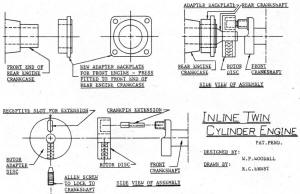

Construction: Three parts are to be made: 1) A new back-plate

for the front engine, which is press fitted on the rear engine's

crankcase (made from hard aluminum); 2) A rotor adapter disc which

fastens to the rear engine's crankshaft (made from cold rolled steel);

3) A small pin pressed into the role made in the crank of the front

engine's shaft (made from drill rod).

The rotor adapter disc is fastened to the crankshaft by counter

sinking a hole at desired position into the shaft. An allen screw

(as shown in sketch) is used for this purpose. The threaded part

of the rear crankshaft is removed flush with the rotor adapter disc.

The rotor adapter has a counter-sink to fit the added pin placed

in the front crank hole which links the two crankshafts. This rotor

adapter disc is so placed that after the crankshaft linkage is made,

each crank will be exactly opposite or 180 degrees to the other.

When these parts are in place the engines may be united and fastened

with four backplate screws. A brace made of 1/8" hard aluminum is

bolted on each side to the normal motor mounts, giving added strength

and new mounting areas. I used only one 4-40 bolt with a lock washer

on either side for mounting to the airplane. The linking and adjusting

of the carburetors and exhaust baffles should be made to make the

carburetors and exhaust baffles open and close the same. This has

a decided effect on the idling characteristics of the engine.

Three K&B .19's confirmed combinations almost

limitless.

Conclusion: My opinion is that the alternate-firing twin-cylinder

engine, equal and unequal displacement combinations, has a definite

advantage over the simultaneous-firing (opposed) engines, only in

better idling, and linear throttle. Vibration tendencies are about

the same.

I have had many hours of pleasure flying these different engines.

All of them have performed well - in the air and on the ground.

I sincerely believe it will be worth your time to construct one

of these combinations and fortunately for those without the necessary

equipment or time, Champion Products, 5620 New Peachtree Rd., Chamblee,

Ga. is now tooling to produce the K&B Twin-29 RC.

Inline Twin Cylinder Engine Mechanical Drawing.

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted May 2, 2015

|